Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sanforizing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

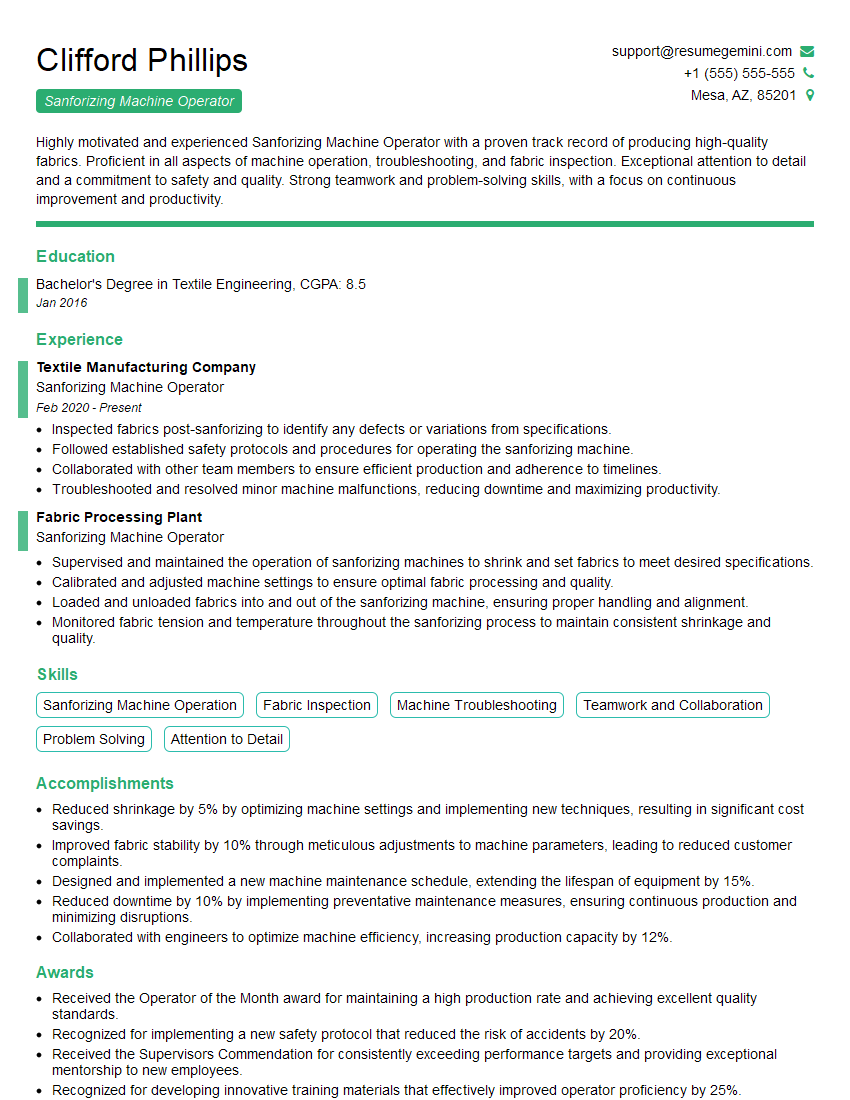

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sanforizing Machine Operator

1. Can you describe the key responsibilities of a Sanforizing Machine Operator?

- Operate the Sanforizing machine to shrink and finish woven cotton fabric.

- Set up and adjust the machine according to the fabric specifications.

- Monitor the machine during operation and make necessary adjustments to ensure fabric quality.

- Inspect the finished fabric for defects and take corrective action.

- Maintain the machine and perform minor repairs as needed.

2. What are the different types of Sanforizing machines and their key features?

a) Tensionless Sanforizing Machine

- No tension is applied to the fabric during the shrinking process.

- Suitable for delicate fabrics that can’t withstand high tension.

b) Pin-Type Sanforizing Machine

- Fabric is pinned to a series of pins before entering the shrinking chamber.

- Provides better control over fabric shrinkage and prevents distortion.

c) Jet-Type Sanforizing Machine

- Uses high-pressure jets of water to shrink the fabric.

- Suitable for heavy fabrics such as canvas and denim.

3. What is the ideal temperature and moisture level required for Sanforizing?

- Temperature: 200-250 degrees Fahrenheit (93-121 degrees Celsius)

- Moisture level: 80-90%

- These conditions help the fabric shrink evenly and prevent damage.

4. How do you adjust the Sanforizing machine to achieve the desired shrinkage?

- Adjust the speed of the shrinkage chamber to increase or decrease the exposure time to heat and moisture.

- Adjust the tension rollers to control the fabric tension and prevent puckering or stretching.

- Modify the steam pressure or water temperature to alter the intensity of the shrinking process.

5. What are the common defects that can occur during Sanforizing and how do you rectify them?

- Reduce the fabric tension or adjust the steam pressure.

- Increase the fabric tension or reduce the shrinkage time.

- Check the tension rollers and ensure uniform pressure across the fabric.

- Investigate the cause of damage (e.g., excessive heat, moisture, or mechanical issues) and take corrective action.

a) Puckering

b) Stretching

c) Shrinkage variation

d) Fabric damage

6. How do you ensure the quality of finished fabric after Sanforizing?

- Inspect the fabric for defects (e.g., shrinkage variation, discoloration, or contamination).

- Measure the shrinkage percentage to ensure compliance with specifications.

- Conduct regular maintenance checks to keep the machine in good condition and prevent breakdowns.

- Maintain accurate records of machine settings and finished fabric quality.

7. What safety precautions should be followed while operating a Sanforizing machine?

- Wear proper safety gear such as gloves, mask, and protective clothing.

- Keep work area clean and free of hazards (e.g., tripping hazards, slippery floors, or exposed wires).

- Lock out and tag out the machine before performing maintenance or repairs.

- Never touch or adjust the machine while it’s in operation.

- Follow all safety protocols and report any potential hazards or accidents promptly.

8. What maintenance tasks do you perform on the Sanforizing machine to keep it in good working order?

- Regularly clean and lubricate all moving parts.

- Inspect and replace belts, gaskets, or other components as needed.

- Check the steam pressure and water system for leaks or malfunctions.

- Calibrate the sensors and ensure accurate readings.

- Follow manufacturer’s guidelines for maintenance and repairs.

9. How do you troubleshoot common Sanforizing machine problems?

- Check tension rollers, steam pressure, and fabric specifications.

- Inspect steam lines, pressure valves, and cooling systems.

- Investigate the source of contamination (e.g., lubricants, cleaning agents, or foreign objects).

- Check the foundation, belts, and bearings for any issues.

a) Fabric shrinkage variation

b) Machine overheating

c) Fabric contamination

d) Machine vibration

10. How do you stay updated with the latest advancements in Sanforizing technology?

- Attend industry conferences and trade shows.

- Read technical articles and journals.

- Consult with machinery manufacturers and experts.

- Participate in online forums and discussions.

- Continuously seek opportunities for professional development and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sanforizing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sanforizing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sanforizing Machine Operator is responsible for operating and maintaining a sanforizing machine, a specialized piece of equipment used in textile finishing to stabilize and shrink fabrics.

1. Machine Operation

The primary responsibility of a Sanforizing Machine Operator is to operate the sanforizing machine efficiently and safely.

- Load and unload fabric rolls onto the machine.

- Adjust machine settings such as tension, temperature, and speed.

- Monitor the machine during operation and make necessary adjustments.

2. Fabric Handling

Sanforizing Machine Operators are also responsible for handling fabrics before and after processing.

- Inspect fabrics for defects and prepare them for sanforizing.

- Properly store finished fabrics and maintain inventory.

- Identify and resolve any fabric-related issues during the sanforizing process.

3. Machine Maintenance

To ensure optimal machine performance, Sanforizing Machine Operators are tasked with basic maintenance and troubleshooting.

- Perform regular cleaning and lubrication of the machine.

- Identify and resolve minor machine malfunctions.

- Report any major maintenance issues to supervisors.

4. Quality Control

Sanforizing Machine Operators are responsible for maintaining the quality of finished fabrics.

- Inspect fabrics after sanforizing to ensure compliance with specifications.

- Identify and correct any quality issues that arise during processing.

- Work closely with quality control personnel to maintain high standards.

Interview Tips

To ace the interview for a Sanforizing Machine Operator position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and understanding of the company you’re applying to and the textile industry in general.

- Visit the company website and learn about their products, services, and mission.

- Read industry publications and articles to stay up-to-date on trends and best practices.

2. Practice Machine Operation Knowledge

Highlight your proficiency in operating sanforizing machines.

- Describe your experience with different types of sanforizing machines.

- Explain the principles of sanforizing and how you ensure fabric stability and shrinkage.

3. Emphasize Fabric Handling Expertise

Showcase your skills in handling and inspecting fabrics.

- Discuss your methods for identifying and resolving fabric defects.

- Explain your knowledge of different fabric types and their handling requirements.

4. Highlight Maintenance and Troubleshooting Abilities

Emphasize your competence in maintaining and troubleshooting sanforizing machines.

- Describe your experience in performing routine maintenance tasks.

- Give examples of how you have resolved common machine malfunctions.

5. Prepare Questions for the Interviewers

Asking thoughtful questions demonstrates your engagement and interest in the role.

- Inquire about the company’s production process and quality standards.

- Ask about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sanforizing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!