Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sanitation Worker, Hosing Machinery position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

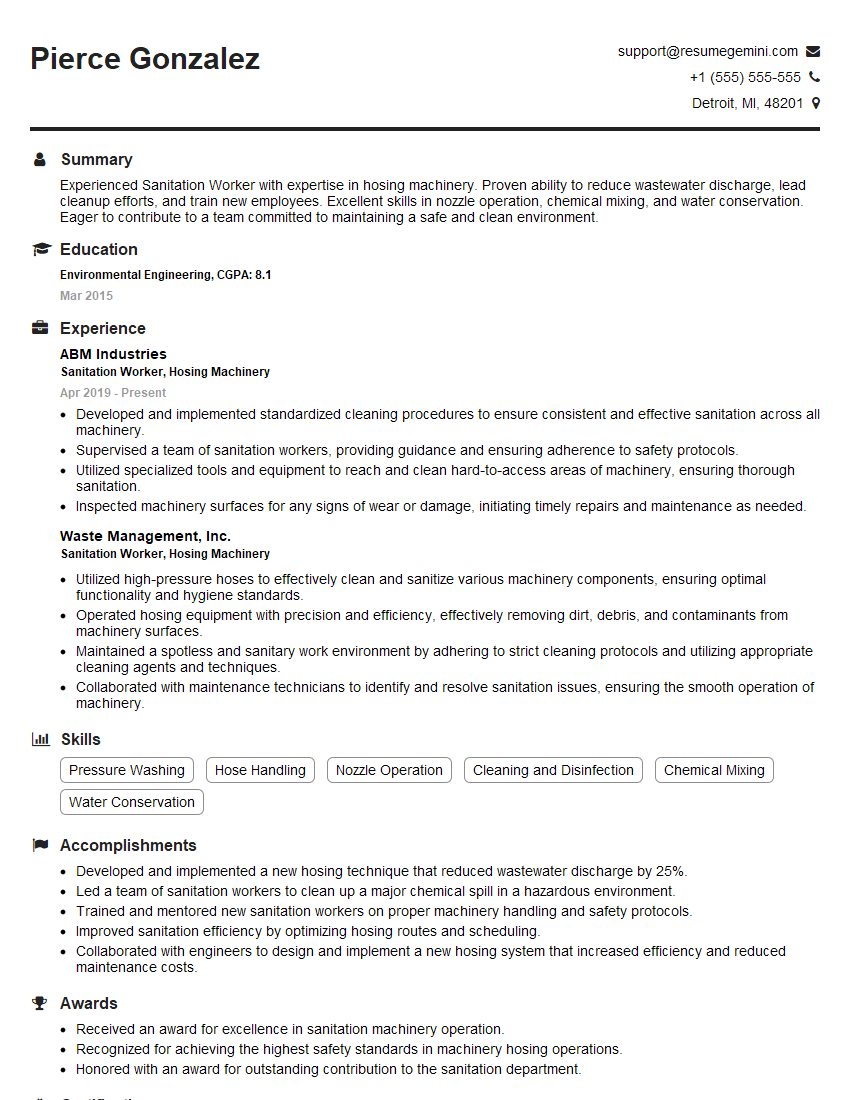

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sanitation Worker, Hosing Machinery

1. Which types of cleaning agents are commonly used to remove debris and dirt from surfaces during sanitation operations, and what are their respective strengths and weaknesses?

- Acids: Acids are effective in removing mineral deposits, rust, and hard water stains. However, they can be corrosive and damage some surfaces like marble or granite.

- Bases: Bases are good for removing organic matter, such as grease, oil, and food residue. They can be caustic and irritate skin or eyes.

- Detergents: Detergents are surfactants that break down dirt and grease, making them easier to remove. They are generally mild and safe for most surfaces.

- Solvents: Solvents are used to dissolve and remove stubborn stains, such as paint or adhesives. However, they can be flammable and toxic.

2. Besides cleaning and disinfecting, what other important safety protocols should be followed when using hosing machinery, including personal protective equipment (PPE) and proper handling techniques?

When using hosing machinery, it’s essential to follow safety protocols to prevent injuries and accidents. These protocols include:

PPE

- Wearing appropriate PPE such as gloves, safety glasses, and protective clothing to avoid exposure to chemicals and debris.

- Using respirators when working in areas with hazardous fumes or dust.

Proper Handling Techniques

- Inspecting the hose and machinery before use to ensure they are in good working condition.

- Operating the machinery according to the manufacturer’s instructions.

- Never pointing the hose at people or electrical equipment.

- Using the correct nozzle for the task and adjusting the water pressure accordingly.

- Being aware of surroundings and potential hazards like slippery surfaces or obstacles.

3. Describe the key components of a hosing machinery system and explain their functions.

- Water Source: The water source can be a tap, reservoir, or water tank. It provides the water supply for the system.

- Pump: The pump generates the water pressure necessary for hosing. It can be powered by electricity, gasoline, or diesel.

- Hose: The hose is a flexible tube that carries the water from the pump to the nozzle.

- Nozzle: The nozzle controls the water flow and spray pattern. Different nozzles are available for various cleaning tasks.

- Accessories: Accessories like brushes, wands, and extensions can enhance the functionality of the system for specific cleaning applications.

4. Explain the importance of proper maintenance and inspection of hosing machinery to ensure optimal performance and safety.

- Regular maintenance extends the equipment’s lifespan and prevents breakdowns during operation.

- Inspections identify potential issues like leaks, blockages, or worn components, allowing for timely repairs or replacements.

- Well-maintained machinery operates efficiently, saving on water and energy consumption.

- Proper maintenance reduces the risk of accidents and injuries caused by malfunctioning equipment.

- Scheduled inspections and maintenance ensure compliance with safety regulations and industry standards.

5. How do you prioritize and organize your cleaning tasks to ensure that critical areas are addressed efficiently while maintaining overall cleanliness?

- Prioritize Areas: Identify areas that require immediate attention based on hygiene standards and foot traffic.

- Create a Cleaning Plan: Establish a schedule that allocates specific tasks to each day or shift.

- Break Down Tasks: Divide large cleaning areas into smaller sections for efficient coverage.

- Use the Right Tools: Select appropriate cleaning agents and equipment for each surface and task.

- Delegate Responsibilities: If working in a team, assign tasks to team members based on their skills and experience.

- Regular Monitoring: Conduct regular inspections to ensure that all areas are cleaned to the required standards.

6. What strategies do you employ to minimize water usage while effectively cleaning and disinfecting surfaces?

- Use Nozzles Efficiently: Choose nozzles that optimize water flow and reduce overspray.

- Adjust Water Pressure: Adjust the water pressure to the appropriate level for the task, avoiding excessive use.

- Target Cleaning: Focus on cleaning specific areas rather than hosing down entire surfaces.

- Use Dry Cleaning Methods: Consider using dry cleaning methods like vacuuming or sweeping for areas where hosing is not necessary.

- Maintain Equipment: Keep hoses and nozzles in good condition to prevent leaks and wastage.

7. How do you handle and dispose of chemicals and cleaning agents safely and in compliance with environmental regulations?

- Read Safety Data Sheets (SDS): Familiarize yourself with the SDS of each chemical to understand its hazards and proper handling.

- Wear PPE: Use appropriate PPE, including gloves, safety glasses, and respirators when handling chemicals.

- Follow Dilution Instructions: Dilute chemicals according to the manufacturer’s instructions to avoid overconcentration.

- Use Spill Kits: Keep spill kits readily available to contain and clean up any spills promptly.

- Proper Disposal: Dispose of used chemicals and cleaning agents at designated waste disposal facilities.

8. What techniques do you use to clean hard-to-reach areas during sanitation operations?

- Use Extension Poles: Attach extension poles to brushes or nozzles to reach high or awkward areas.

- Use Specialized Nozzles: Choose nozzles with angled or rotating heads to clean hard-to-reach corners and crevices.

- Manual Cleaning: Use brushes, sponges, or cloths for detailed cleaning of intricate areas.

- Consider Alternative Methods: Explore using steam cleaners or dry ice blasting for deep cleaning in hard-to-reach spaces.

- Inspect Regularly: Conduct regular inspections to identify areas that require special attention during cleaning.

9. How do you ensure the proper storage and maintenance of sanitation equipment and supplies to maintain their functionality and longevity?

- Designated Storage Area: Establish a dedicated storage area for equipment and supplies to prevent clutter and damage.

- Regular Cleaning: Clean and disinfect equipment regularly to prevent contamination and ensure optimal performance.

- Inspections: Conduct regular inspections to identify any damages or maintenance needs.

- Proper Storage: Store equipment and supplies in a dry, well-ventilated area to prevent rust and corrosion.

- Follow Manufacturer’s Instructions: Refer to the manufacturer’s instructions for specific storage and maintenance guidelines.

10. How do you stay updated on the latest advancements and best practices in sanitation techniques and equipment?

- Attend Industry Events: Participate in conferences, workshops, and trade shows to learn about new technologies and techniques.

- Read Industry Publications: Subscribe to industry magazines and journals to stay informed about best practices and advancements.

- Seek Training Opportunities: Attend training sessions or workshops offered by equipment manufacturers or industry organizations.

- Network with Colleagues: Connect with other professionals in the field to exchange knowledge and ideas.

- Research Online: Explore online resources, such as industry websites and forums, to access up-to-date information.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sanitation Worker, Hosing Machinery.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sanitation Worker, Hosing Machinery‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sanitation Workers, Hosing Machinery, play a vital role in maintaining cleanliness and hygiene in various settings. Their primary duties involve:

1. Machinery Operation

Skilfully operate industrial-grade hosing machinery to clean and sanitize equipment, facilities, and vehicles.

- Adjust water pressure, nozzle settings, and chemical concentrations to achieve optimal cleaning results.

- Follow safety protocols and proper handling techniques to prevent injuries and damage to equipment.

2. Cleaning and Sanitation

Perform deep cleaning tasks using high-powered water jets and specialized detergents.

- Remove dirt, debris, grease, and other contaminants from surfaces and equipment.

- Sanitize surfaces to eliminate bacteria, viruses, and other microorganisms.

3. Equipment and Waste Management

Maintain and inspect hosing machinery to ensure optimal performance.

- Handle and dispose of wastewater and hazardous materials in accordance with environmental regulations.

- Keep work areas clean and organized, ensuring compliance with safety and hygiene standards.

4. Physical Labor

Exert physical effort to operate heavy equipment and perform cleaning tasks.

- Lift and move heavy objects, operate handheld tools, and engage in extended periods of standing and walking.

- Endure exposure to various environmental conditions, including extreme temperatures and loud noises.

Interview Tips

To ace the interview for a Sanitation Worker, Hosing Machinery position, candidates should demonstrate their familiarity with the role, enthusiasm for the work, and ability to perform physical tasks effectively. Here are some tips:

1. Research the Role and Industry

Thoroughly research the position and the company to gain a clear understanding of the job requirements and company culture.

- Review the job description and identify key responsibilities and skills.

- Visit the company’s website and learn about their values, mission, and industry standing.

2. Highlight Relevant Experience

Emphasize your previous experience operating hosing machinery or performing similar cleaning and sanitation tasks.

- Quantify your accomplishments and provide specific examples of how you contributed to maintaining cleanliness and hygiene.

- Explain how your skills and abilities align with the job requirements.

3. Demonstrate Physical Capabilities

Convincingly demonstrate your physical capabilities and willingness to perform physically demanding tasks.

- Discuss your experience in lifting heavy objects, operating machinery, and working in strenuous conditions.

- Convey your ability to work independently and as part of a team.

4. Emphasize Safety and Compliance

Showcase your commitment to safety and compliance with environmental regulations.

- Highlight your knowledge of safety protocols and best practices for handling hazardous materials.

- Explain your understanding of environmental regulations and your willingness to adhere to them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sanitation Worker, Hosing Machinery interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!