Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sausage Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

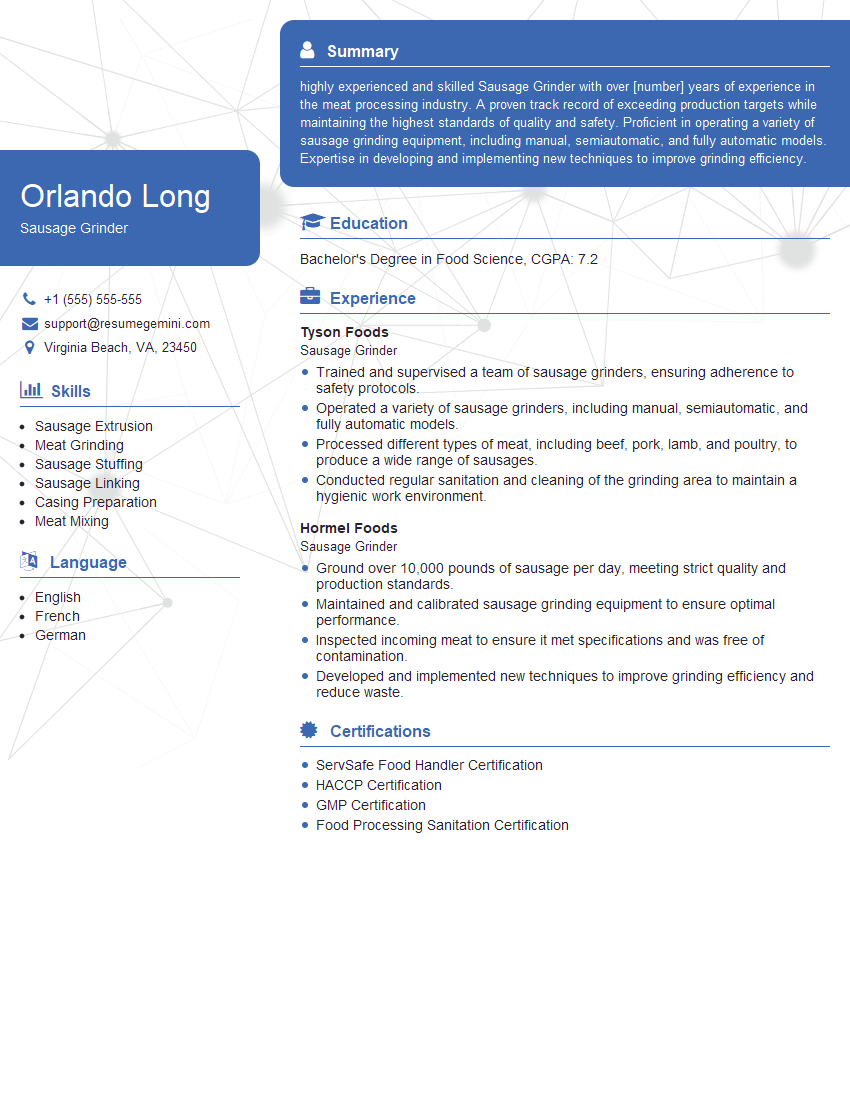

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sausage Grinder

1. How do you ensure the efficiency of the grinding process to minimize waste and maximize yield?

- Regularly calibrate and maintain the grinder to ensure precise cuts and consistent particle size.

- Use sharp blades to prevent tearing and ensure clean cuts, resulting in less waste.

- Optimize the grinding speed and feed rate to achieve the desired texture and minimize the generation of fines.

- Employ a pre-grinding stage to break down larger pieces and improve the efficiency of the main grinding process.

- Monitor the temperature of the meat during grinding to prevent it from becoming too warm, which can lead to increased waste and reduced product quality.

2. What sanitation and hygiene practices do you follow to ensure the safety and quality of the ground product?

subheading of the answer

- Thoroughly clean and sanitize all equipment, surfaces, and utensils before and after use to prevent cross-contamination.

- Maintain proper hand hygiene by washing hands frequently and using gloves when handling meat.

- Implement HACCP principles to identify and control potential hazards throughout the grinding process.

- Use food-grade lubricants and cleaning solutions specifically designed for use in food processing environments.

- Regularly monitor the temperature of the meat and the grinding environment to prevent bacterial growth.

subheading of the answer

- Follow established sanitation protocols and industry best practices to ensure the production of safe and hygienic ground meat products.

- Undergo regular training and certification to stay updated on the latest food safety regulations and best practices.

- Promote a culture of food safety awareness and responsibility among all staff members involved in the grinding process.

3. How do you handle different types of meat and adjust the grinding process accordingly?

- Adjust the grinding plate size and blade configuration to suit the texture and fat content of the meat.

- Consider the temperature of the meat and adjust the grinding speed to prevent smearing or excessive heat generation.

- Use specialized grinding attachments for specific types of meat, such as a coarse plate for grinding beef or a fine plate for grinding fish.

- Experiment with different grinding techniques to achieve the desired consistency and texture for each type of meat.

- Consult with chefs or food technologists to determine the optimal grinding parameters for various meat products.

4. How do you troubleshoot common problems that may arise during the grinding process?

- Identify the source of the problem by observing the grinding process and examining the equipment.

- Check for dull blades, improper plate alignment, or blockages in the grinder.

- Adjust the grinding parameters, such as speed, feed rate, or blade sharpness, to resolve the issue.

- Clean and sanitize the grinder thoroughly to remove any debris or contaminants that may be causing problems.

- Consult with a supervisor or maintenance technician if the problem persists or is beyond your capabilities.

5. How do you ensure the accuracy and consistency of the ground product?

- Calibrate the grinder regularly using standard weights and measures to ensure accurate grinding.

- Monitor the grind size throughout the process using a particle size analyzer or visual inspection.

- Adjust the grinding parameters as needed to maintain consistency in the ground product.

- Document the grinding process and parameters to ensure repeatability and traceability.

- Implement quality control measures to verify the accuracy and consistency of the final product.

6. What maintenance procedures do you perform on the grinding equipment to ensure its optimal performance?

- Regularly clean and sanitize all parts of the grinder, including the hopper, auger, plates, and blades.

- Inspect the blades for sharpness and replace them when necessary to ensure efficient cutting.

- Lubricate moving parts according to the manufacturer’s recommendations to minimize friction and wear.

- Check the alignment of the grinding plates and adjust them as needed to prevent uneven grinding.

- Perform preventive maintenance tasks, such as belt tensioning and bearing replacement, to extend the life of the equipment.

7. How do you stay updated on the latest advancements in grinding technology and best practices?

- Attend industry conferences and exhibitions to learn about new equipment and technologies.

- Read trade publications and technical journals to stay informed about the latest research and advancements.

- Network with other professionals in the field to exchange knowledge and ideas.

- Participate in training programs offered by equipment manufacturers or industry organizations.

- Seek opportunities to collaborate with food technologists and researchers to gain insights into emerging trends and best practices.

8. How do you handle and resolve customer complaints related to the quality of the ground product?

- Listen attentively to the customer’s complaint and gather all relevant information.

- Investigate the issue thoroughly to identify the root cause of the problem.

- Communicate the findings to the customer in a clear and empathetic manner.

- Take appropriate action to resolve the issue, such as adjusting the grinding parameters or replacing defective parts.

- Follow up with the customer to ensure their satisfaction and build trust.

9. How do you prioritize and manage multiple tasks in a fast-paced grinding environment?

- Assess the urgency and importance of each task to determine the order of priority.

- Break down complex tasks into smaller, more manageable steps to make them less overwhelming.

- Delegate tasks to other team members when necessary to avoid bottlenecks.

- Utilize time management techniques, such as the Pomodoro Technique, to stay focused and avoid distractions.

- Communicate effectively with colleagues to coordinate and avoid overlapping tasks.

10. How do you contribute to the overall efficiency and productivity of the grinding operation?

- Optimize the grinding process to minimize waste and maximize yield.

- Identify and implement process improvements to increase efficiency and productivity.

- Train and mentor new employees to ensure a skilled and knowledgeable workforce.

- Maintain a clean and organized work area to reduce downtime and promote efficiency.

- Collaborate with other departments to streamline processes and improve communication.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sausage Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sausage Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Sausage Grinder is responsible for a vital role in the production process, ensuring the efficient and consistent grinding of meat and other ingredients for sausage production. The core job responsibilities include:

1. Grinding Meat and Ingredients

Using industrial-grade sausage grinders, the primary task of the Sausage Grinder is to grind meat and other ingredients such as spices, herbs, and seasonings to create the desired sausage texture.

- Operate and maintain sausage grinders, ensuring optimal performance and safety.

- Adjust grinder settings to achieve the desired sausage texture and consistency.

2. Monitoring Production Process

To maintain quality standards, the Sausage Grinder monitors the production process to ensure that the grinding meets specifications and standards.

- Monitor the grinding process to prevent blockages or jams in the grinder.

- Check the consistency and texture of the ground sausage against established standards.

3. Equipment Maintenance and Sanitation

For efficient and hygienic operations, the Sausage Grinder is responsible for maintaining and cleaning the sausage grinders and related equipment.

- Clean and sanitize sausage grinders, work surfaces, and tools to meet safety and hygiene standards.

- Perform routine maintenance and repairs on sausage grinders to ensure optimal performance.

4. Quality Control

The Sausage Grinder plays a crucial role in ensuring the quality of the sausage products by adhering to established quality standards and specifications.

- Check the ground sausage for foreign objects, defects, or contamination.

- Report any quality issues or concerns to the supervisor promptly.

Interview Tips

Preparing for a Sausage Grinder interview can increase your chances of success. Here are some essential interview tips to help you ace the interview:

1. Research the Company and Role

Take the time to research the company’s history, values, and the specific responsibilities of the Sausage Grinder role. This knowledge demonstrates your interest and preparation.

- Visit the company website and read about their products, services, and industry reputation.

- Review the job description thoroughly and identify the key skills and qualifications required.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the job requirements. Quantify your accomplishments and provide specific examples to demonstrate your abilities.

- Mention your experience operating and maintaining sausage grinders or similar equipment.

- Highlight your knowledge of sausage production processes and quality control standards.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation for the role. Practice your answers to ensure clarity and conciseness.

- Prepare answers to questions about your experience in grinding meat and other ingredients.

- Practice describing your understanding of sausage production processes and quality control measures.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows respect for the interviewer and the company.

- Choose clean and pressed clothing that is appropriate for an industrial setting.

- Plan your route and allow ample time for travel to ensure you arrive punctually.

Next Step:

Now that you’re armed with the knowledge of Sausage Grinder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sausage Grinder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini