Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sausage Stringer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sausage Stringer so you can tailor your answers to impress potential employers.

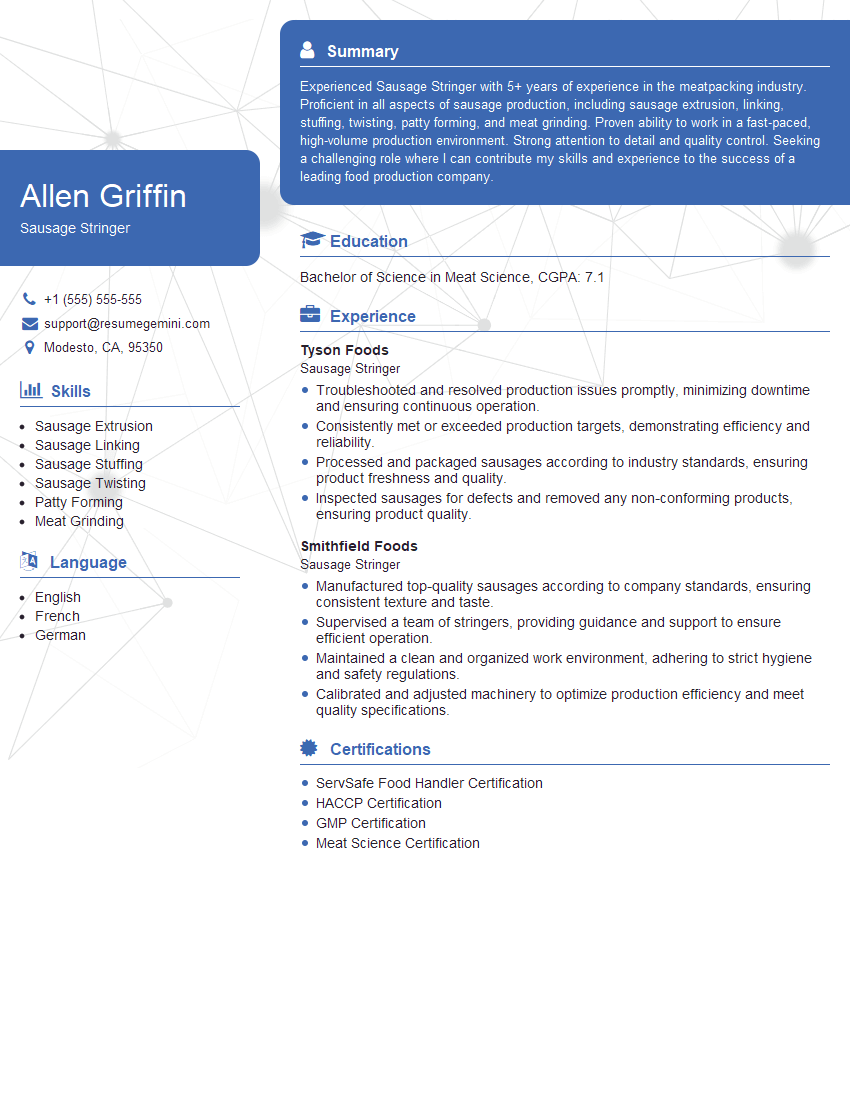

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sausage Stringer

1. Describe the process of sausage stringing in detail.

- Preparing the sausage mixture: The first step involves mixing and grinding the meat, spices, and seasonings to create the sausage mixture.

- Extruding the mixture: The prepared mixture is then fed into an extruder that forces it through a narrow nozzle, forming the sausage casings.

- Linking the sausages: As the mixture is extruded, it passes through a linker that twists and forms individual sausages.

- Hanging and drying: The linked sausages are hung in a controlled environment to allow them to dry and develop their desired texture and flavor.

2. Explain the different types of sausage stringing machines and their applications.

Semi-automatic machines

- Manually load the mixture into the machine.

- Suitable for small-scale production or operations with limited space.

Fully automatic machines

- Automate the entire stringing process.

- Higher production rates and consistency.

3. What factors should be considered when selecting sausage casings?

- Type of sausage: Different sausages require specific casings based on their size, texture, and desired presentation.

- Permeability: The casing should allow for appropriate moisture retention or release to achieve the desired texture.

- Strength and elasticity: The casing should be strong enough to handle the filling and stringing process without tearing.

4. How do you ensure the quality and consistency of sausages during stringing?

- Properly calibrated machines: Ensure accurate filling and linking.

- Monitoring ingredient ratios and temperature: Maintain consistent product quality.

- Visual inspection: Regularly check sausages for defects or inconsistencies.

- Adhering to hygiene protocols: Prevent contamination and maintain food safety.

5. Describe the troubleshooting techniques for common sausage stringing issues.

- Uneven filling: Check the extruder nozzle for clogs or obstructions.

- Broken casings: Inspect the casings for damage or weakness, and adjust the machine settings accordingly.

- Incorrect linking: Ensure the linker is properly adjusted and lubricated.

- Sausage too dry: Adjust the hydration level of the mixture or consider using casings with higher permeability.

6. What are the safety precautions that must be followed while operating sausage stringing machines?

- Wear appropriate protective gear: Gloves, hair nets, and non-slip shoes.

- Keep hands away from moving parts: Prevent injuries during operation.

- Ensure proper machine guarding: Protect operators from potential hazards.

- Follow lockout/tagout procedures: Prevent accidental machine activation during maintenance.

7. How do you maintain and clean sausage stringing machines to ensure optimal performance?

- Regular cleaning: Remove any food residue or debris after each use.

- Lubrication: Apply lubricant to moving parts as per manufacturer’s recommendations.

- Calibration: Ensure machine settings are accurate to maintain consistent product quality.

- Preventive maintenance: Schedule regular inspections and repairs to prevent breakdowns.

8. Describe the different types of sausage stuffing horns and their uses.

- Plain horns: For filling straight sausages with no bends.

- Curved horns: For filling sausages with angles or curves.

- Funnel horns: For filling large-diameter sausages or products with specific shapes.

9. How do you determine the correct stuffing pressure for different types of sausages?

- Sausage texture: Firmer sausages require higher pressure.

- Casing type: Delicate casings require lower pressure to prevent breakage.

- Machine specifications: Follow manufacturer’s guidelines for optimal pressure settings.

10. What are the common mistakes to avoid when stuffing sausages?

- Overstuffing: Can cause casings to burst.

- Understuffing: Can result in loose and uneven sausages.

- Air pockets: Can create voids within the sausage, affecting texture and shelf life.

- Improper tying: Can lead to sausages falling apart during cooking.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sausage Stringer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sausage Stringer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sausage Stringers are responsible for operating a sausage stringing machine to fill and link sausages. They ensure that the machine is operating correctly and make adjustments as needed. Additionally, they monitor the quality of the sausages and make sure that they meet company standards.

1. Preparing the Machine

Sausage Stringers start their day by preparing the sausage stringing machine. This involves cleaning the machine, attaching the necessary nozzles, and setting the correct operating parameters.

2. Operating the Machine

Once the machine is prepared, Sausage Stringers begin operating it. They load the sausage meat into the hopper and start the machine. They monitor the machine’s operation and make adjustments as needed to ensure that the sausages are being filled and linked correctly.

3. Monitoring Sausage Quality

Sausage Stringers are responsible for monitoring the quality of the sausages being produced. They check the sausages for defects, such as tears or uneven filling. They also check the weight and size of the sausages to ensure that they meet company standards.

4. Cleaning and Sanitation

Sausage Stringers are responsible for cleaning and sanitizing the sausage stringing machine and work area. They clean the machine after each use and sanitize it regularly to prevent the growth of bacteria.

Interview Tips

Preparing for an interview for a Sausage Stringer position can be daunting, but following these tips can help you ace the interview and land the job.

1. Research the Company and the Position

Before the interview, take some time to research the company you are applying to and the Sausage Stringer position. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked during an interview for a Sausage Stringer position. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the Sausage Stringer position. Emphasize your ability to operate a sausage stringing machine, monitor sausage quality, and clean and sanitize the work area.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the job and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sausage Stringer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!