Feeling lost in a sea of interview questions? Landed that dream interview for Saw Repairer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Saw Repairer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

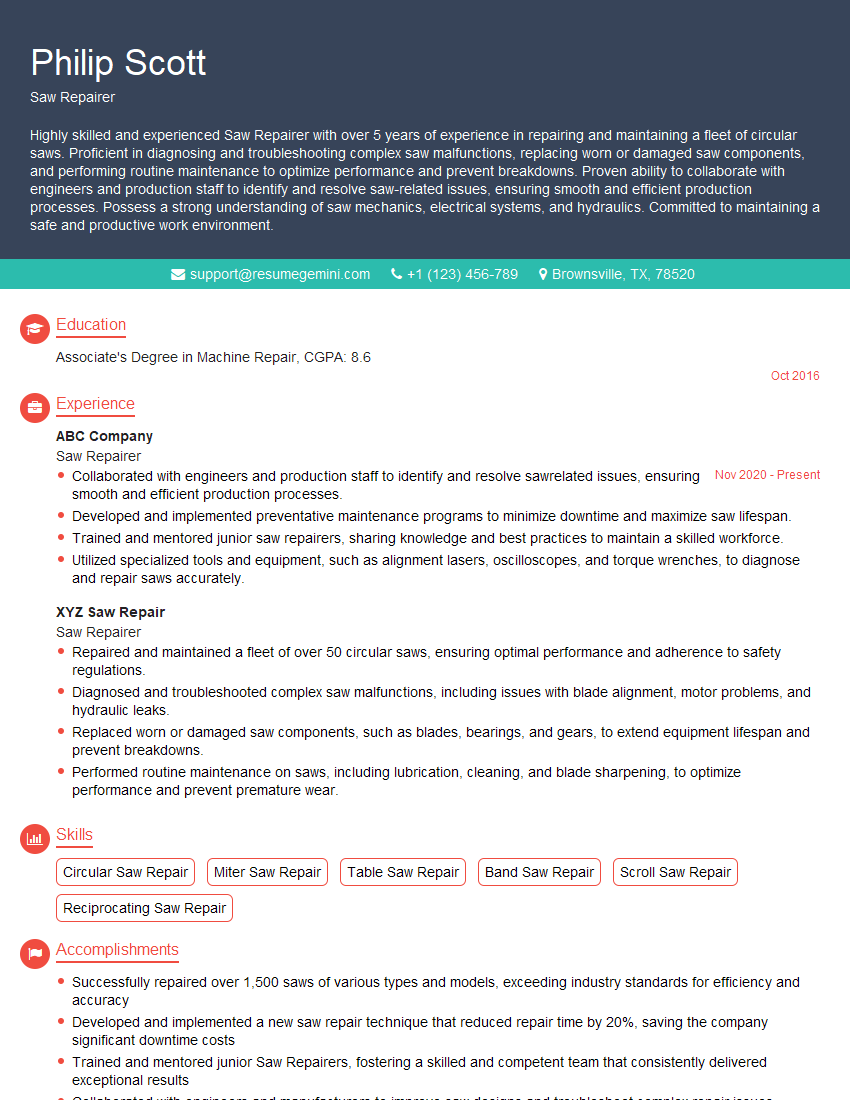

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Saw Repairer

1. What are the common types of saw blades and their uses?

There are various types of saw blades, each designed for specific cutting applications. Some common types include:

- Circular saw blades: Used for crosscutting, ripping, and miter cuts in wood, plastic, and metal.

- Bandsaw blades: Flexible blades used for cutting curves and irregular shapes in wood and metal.

- Reciprocating saw blades: Straight blades used for cutting through various materials, including wood, metal, and drywall.

- Jigsaw blades: Thin, narrow blades used for making precise cuts and intricate designs in wood, metal, and plastic.

- Chain saw blades: Toothed blades used for cutting trees and other large pieces of wood.

2. Explain the safety precautions you take when repairing and servicing saws.

Personal Protective Equipment

- Wear appropriate PPE, such as safety glasses, gloves, and earplugs.

- Use proper lifting techniques to avoid injuries.

Work Environment

- Ensure a well-lit and ventilated work area.

- Keep tools and equipment organized and in good condition.

Electrical Safety

- Disconnect the saw from the power source before servicing.

- Use caution when handling electrical components.

Blade Handling

- Wear cut-resistant gloves when handling saw blades.

- Dispose of used blades properly.

3. Describe the process of diagnosing and troubleshooting common saw problems.

Process of Troubleshooting Common Saw Problems:

- Identify the problem: Observe the symptoms and gather relevant information.

- Inspect the saw: Check for loose parts, damaged components, or other potential causes.

- Test the saw: Safely run the saw to isolate the issue.

- Consult manuals or technical resources: Refer to documentation for specific troubleshooting steps.

- Replace or repair components: Identify and replace or repair faulty components as needed.

- Reassemble and test: Reassemble the saw and test it to ensure proper function.

4. What are the key maintenance tasks for saws?

- Regular cleaning and lubrication of moving parts.

- Sharpening or replacing saw blades as needed.

- Inspecting electrical components and connections.

- Testing safety features, such as blade guards.

- Adhering to manufacturer’s maintenance schedule.

5. What are the different types of saw sharpening techniques?

- Manual sharpening using a file: Requires skill and practice to achieve precision.

- Machine sharpening: Uses specialized machines to sharpen blades quickly and accurately.

- Laser sharpening: Employs laser technology for high-precision sharpening.

- Diamond sharpening: Utilizes diamond abrasive wheels for exceptional sharpness and durability.

6. How do you ensure the accuracy and precision of saw cuts?

- Use a sharp saw blade and adjust it properly.

- Secure the workpiece firmly using clamps or a vise.

- Follow marked guidelines or use a straight edge for precise cuts.

- Calibrate the saw regelmäßig and check for any alignment issues.

- Take your time and concentrate on maintaining a steady hand.

7. What are the safety features found on modern saws?

- Blade guards: Prevent accidental contact with the blade.

- Kickback prevention devices: Minimize the risk of the saw being thrown backward.

- Anti-lock brakes: Help prevent the saw from continuing to spin after the trigger is released.

- Line-of-sight barriers: Block the view of the blade from certain angles, reducing the risk of injury.

- Emergency stop buttons: Allow for quick shut-off in case of an accident.

8. How do you handle and store saw blades safely?

Handling:

- Wear cut-resistant gloves.

- Handle blades by the center hole to avoid touching the sharp edges.

Storage:

- Store blades in a dry, protected location.

- Use blade guards or covers to prevent damage to the blades and protect against accidental cuts.

9. What are the environmental considerations related to saw repair and maintenance?

- Proper disposal of used blades: Follow local regulations and consider recycling programs.

- Use of environmentally friendly lubricants: Opt for biodegradable or non-toxic lubricants to minimize environmental impact.

- Energy efficiency: Utilize energy-efficient saws and tools to reduce energy consumption.

- Noise reduction: Use saws with low noise levels or employ noise-dampening measures to minimize noise pollution.

10. What are the latest advancements in saw technology?

- Laser-guided saws: Enhanced precision and accuracy using laser technology.

- Cordless saws: Greater portability and convenience.

- Smart saws: Integrated sensors and connectivity for enhanced safety and control.

- Self-sharpening blades: Extended blade life and reduced maintenance.

- Variable speed saws: Optimized cutting performance for different materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Saw Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Saw Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Saw Repairers hold the paramount responsibility of maintaining and repairing an array of saws, ensuring optimal performance and safe operation within diverse industries, including woodworking, manufacturing, and construction. Their expertise encompasses:

1. Saw Maintenance and Repair

Performing routine maintenance on saws to prevent breakdowns and extend their lifespan. This includes tasks like changing blades, adjusting tension, and lubricating moving parts.

- Conducting thorough inspections to identify potential issues and address them promptly.

- Disassembling and reassembling saws to replace worn or damaged components.

2. Troubleshooting and Diagnostics

Troubleshooting and diagnosing complex saw malfunctions, employing specialized tools and techniques to pinpoint the root cause of the issue.

- Analyzing operating parameters, studying schematics, and performing tests to isolate the fault.

- Using diagnostic software to identify electrical or mechanical problems.

3. Precision Adjustments and Calibration

Making precise adjustments and calibrations to ensure saws meet specific operational requirements.

- Setting blade angles, fences, and other components to achieve desired cutting accuracy.

- Calibrating saws using specialized tools to ensure precise measurements and cuts.

4. Safety Compliance and Training

Upholding strict safety protocols and providing training to ensure the safe operation of saws.

- Conducting safety inspections, implementing lockout/tagout procedures, and adhering to OSHA regulations.

- Providing training on proper saw operation, maintenance, and safety measures to employees.

Interview Tips

To ace your Saw Repairer interview, consider these preparation tips:

1. Research the Industry and Company

Demonstrate your understanding of the saw repair industry and the specific company you’re applying to. Familiarize yourself with their products, services, and reputation.

- Visit the company’s website, read industry publications, and connect with professionals in the field.

- Research industry trends and advancements to show your knowledge of the latest technologies.

2. Highlight Relevant Experience and Skills

Emphasize your experience in saw repair, maintenance, and troubleshooting. Quantify your accomplishments whenever possible using specific examples.

- Describe the types of saws you’ve worked on and the repairs you’ve performed.

- Mention any certifications or training you possess, such as OSHA or manufacturer-specific certifications.

3. Prepare for Technical Questions

Expect questions that assess your technical knowledge of saws and repair techniques. Practice answering questions about saw components, troubleshooting procedures, and safety protocols.

- Review common saw repair scenarios and how you would approach each issue.

- Be prepared to discuss specific tools and diagnostic equipment used in saw repair.

4. Show Your Safety Consciousness

Saw repairers must prioritize safety. Demonstrate your commitment to safety by highlighting your knowledge of OSHA regulations, lockout/tagout procedures, and proper saw handling techniques.

- Describe your approach to ensuring a safe work environment and preventing accidents.

- Share examples of how you’ve implemented safety measures in previous roles.

5. Be Enthusiastic and Professional

Convey your passion for saw repair and your eagerness to join the team. Maintain a professional demeanor, ask thoughtful questions, and follow up promptly after the interview.

- Express your interest in the company’s mission and how your skills align with their goals.

- Thank the interviewer for their time and reiterate your interest in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Saw Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Saw Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.