Are you gearing up for an interview for a Saw Superintendent position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Saw Superintendent and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

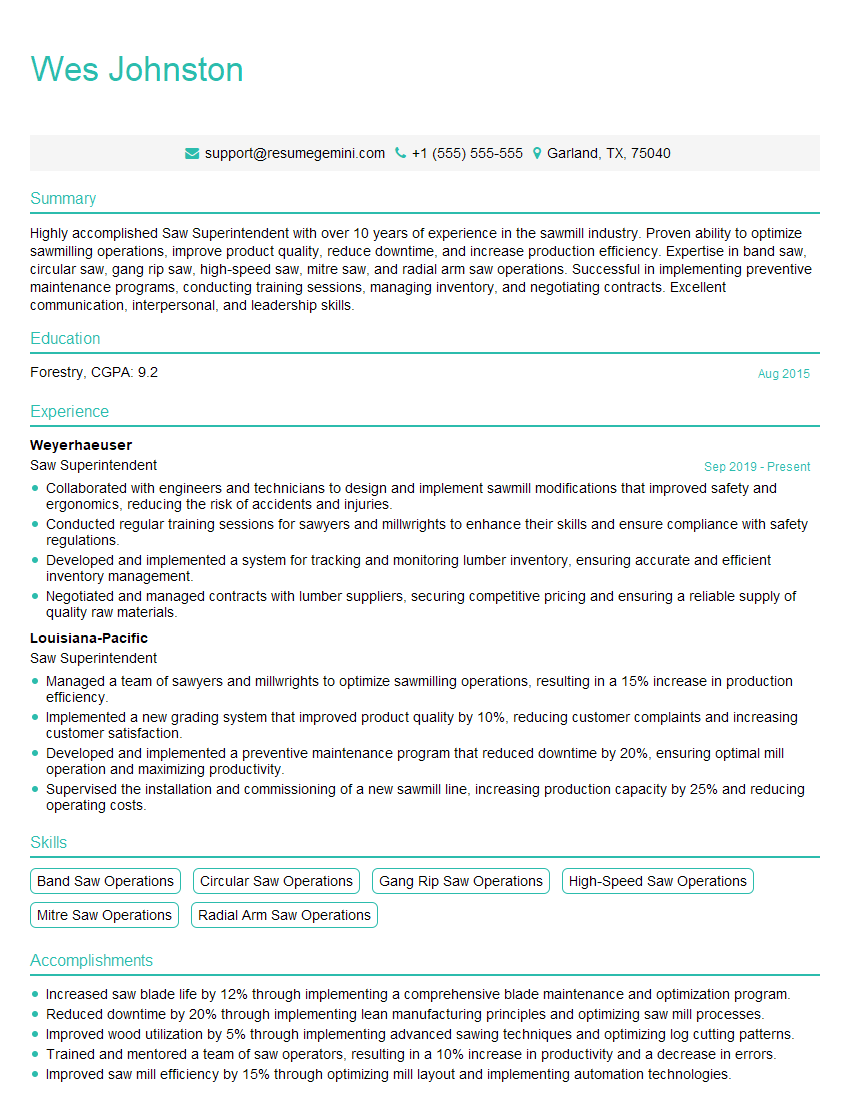

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Saw Superintendent

1. What are the key performance indicators (KPIs) you would use to measure the success of a sawmilling operation?

- Production efficiency: This measures the amount of lumber produced per unit of time. It is important to track this KPI to ensure that the mill is operating at peak efficiency.

- Product quality: This measures the quality of the lumber produced. It is important to track this KPI to ensure that the mill is producing lumber that meets the customer’s specifications.

- Customer satisfaction: This measures the satisfaction of the mill’s customers. It is important to track this KPI to ensure that the mill is meeting the needs of its customers.

- Safety: This measures the safety of the mill’s operations. It is important to track this KPI to ensure that the mill is operating in a safe and efficient manner.

- Cost efficiency: This measures the cost of producing lumber. It is important to track this KPI to ensure that the mill is operating in a cost-effective manner.

2. What are the different types of saws that are commonly used in sawmills?

- Band saws: These saws are made of a long, thin blade that is stretched over two wheels. They are used to cut large logs into smaller pieces.

- Circular saws: These saws are made of a circular blade that is mounted on a shaft. They are used to cut lumber into smaller pieces.

- Gang saws: These saws are made of a series of blades that are mounted on a frame. They are used to cut lumber into multiple pieces at the same time.

- Trim saws: These saws are used to trim the ends of lumber.

3. What are the different types of lumber that are produced in sawmills?

- Softwood lumber: This type of lumber is made from softwood trees, such as pine, fir, and spruce. It is used for a variety of purposes, such as framing, siding, and furniture.

- Hardwood lumber: This type of lumber is made from hardwood trees, such as oak, maple, and cherry. It is used for a variety of purposes, such as flooring, furniture, and cabinetry.

4. What are the different processes involved in sawmilling?

- Log yard operations: This involves the handling and storage of logs.

- Sawing operations: This involves the cutting of logs into lumber.

- Drying operations: This involves the drying of lumber.

- Finishing operations: This involves the finishing of lumber, such as planing, sanding, and staining.

5. What are the different factors that can affect the quality of lumber?

- Log quality: The quality of the lumber produced is dependent on the quality of the logs used.

- Sawing process: The sawing process can affect the quality of the lumber produced. Factors such as the sharpness of the saw blades and the speed of the saw can affect the quality of the cut.

- Drying process: The drying process can affect the quality of the lumber produced. Factors such as the temperature and humidity of the drying kiln can affect the quality of the lumber.

- Finishing process: The finishing process can affect the quality of the lumber produced. Factors such as the type of finish used and the quality of the application can affect the quality of the lumber.

6. What are the different safety hazards that can be present in a sawmill?

- Falling logs: Logs can fall from the log deck or from the sawyer’s carriage. This can cause serious injury or death.

- Moving machinery: Sawmills contain a lot of moving machinery, such as saws, conveyors, and log loaders. This machinery can crush or cut workers.

- Electrical hazards: Sawmills use a lot of electricity to power their machinery. This can create electrical hazards, such as shocks and burns.

- Noise: Sawmills can be very noisy. This can damage workers’ hearing and make it difficult to communicate.

7. What are the different ways to reduce the risk of accidents in a sawmill?

- Proper training: Workers should be properly trained on how to operate machinery and how to work safely in a sawmill.

- Proper safety equipment: Workers should wear proper safety equipment, such as hard hats, safety glasses, and earplugs.

- Regular inspections: Sawmills should be regularly inspected for safety hazards. Any hazards that are identified should be corrected immediately.

- Emergency procedures: Sawmills should have emergency procedures in place in case of an accident. These procedures should be communicated to all workers.

8. What are the different types of maintenance that are required for sawmill equipment?

- Preventive maintenance: This type of maintenance is performed on a regular basis to prevent equipment failures.

- Predictive maintenance: This type of maintenance uses data to predict when equipment is likely to fail. This allows maintenance to be performed before the equipment fails.

- Corrective maintenance: This type of maintenance is performed to repair equipment that has failed.

9. What are the different types of conveyors that are used in sawmills?

- Belt conveyors: These conveyors use a belt to transport materials.

- Chain conveyors: These conveyors use a chain to transport materials.

- Screw conveyors: These conveyors use a screw to transport materials.

- Roller conveyors: These conveyors use rollers to transport materials.

10. What are the different types of dust collection systems that are used in sawmills?

- Cyclone collectors: These collectors use centrifugal force to separate dust from air.

- Bag filters: These collectors use filters to separate dust from air.

- Wet scrubbers: These collectors use water to scrub dust from air.

- Electrostatic precipitators: These collectors use an electrical charge to separate dust from air.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Saw Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Saw Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Saw Superintendent, you will lead a team of saw operators and oversee all aspects of the sawmill operation. Your primary goal is to ensure the efficient and safe production of high-quality lumber while maximizing productivity and profitability. Some key responsibilities include:

1. Production Management

Managing all aspects of the sawmill production process, including planning, scheduling, and optimizing saw patterns to maximize lumber yield and minimize waste.

- Overseeing saw operators and ensuring they are following best practices to produce high-quality lumber.

- Coordinating with other departments, such as logging and lumber handling, to ensure a smooth and efficient operation.

2. Quality Control

Establishing and maintaining quality standards for lumber products. Inspecting lumber for defects and ensuring it meets customer specifications.

- Working with quality control personnel to identify and correct any quality issues.

- Implementing quality improvement programs to continuously enhance the overall quality of lumber.

3. Safety Management

Enforcing safety regulations and protocols to ensure the well-being of employees. Conducting safety training and awareness programs for saw operators.

- Investigating accidents and incidents to identify root causes and implement corrective actions.

- Maintaining a safe and clean work environment to prevent accidents and injuries.

4. Equipment Maintenance

Overseeing the maintenance and calibration of all sawmill equipment. Identifying and prioritizing maintenance needs to prevent breakdowns and minimize downtime.

- Working with maintenance personnel to schedule and perform equipment repairs and replacements.

- Keeping up-to-date on technological advancements and recommending equipment upgrades to enhance efficiency and productivity.

Interview Tips

To ace your interview for a Saw Superintendent position, it’s crucial to prepare thoroughly and demonstrate your knowledge and skills.

1. Research the Company and Position

Thoroughly research the company’s website, industry publications, and social media profiles to understand their operations, culture, and specific requirements for the Saw Superintendent role.

- This will help you tailor your answers to the interviewer’s questions and show that you’re genuinely interested in the position.

- Prepare specific examples from your previous experience that highlight your relevant skills and accomplishments.

2. Practice Common Interview Questions

Anticipate likely interview questions and practice answering them concisely and effectively. Some common questions for Saw Superintendent interviews include:

- “Describe your experience in managing a sawmill operation and optimizing productivity.”

- “How do you handle safety concerns and ensure compliance with regulations?”

- “Tell us about a time when you implemented a successful quality improvement program.”

- “How do you stay up-to-date with the latest sawmilling technologies and advancements?”

- “What are your plans for improving sawmill efficiency and profitability?”

3. Highlight Your Leadership and Management Skills

Saw Superintendents are responsible for leading and managing a team of saw operators. Emphasize your ability to inspire, motivate, and collaborate with others.

- Describe your approach to team management and how you foster a positive and productive work environment.

- Provide specific examples of how you’ve resolved conflicts, provided constructive feedback, and recognized employee achievements.

4. Demonstrate Your Technical Expertise

Saw Superintendents need a deep understanding of sawmill equipment, processes, and industry best practices. Showcase your technical expertise and how it has benefited your previous employers.

- Discuss your experience with different types of sawmilling equipment and how you optimize their performance.

- Explain your knowledge of lumber grading and quality control procedures.

- Share any experience you have with implementing new technologies or automation in a sawmill setting.

Next Step:

Now that you’re armed with the knowledge of Saw Superintendent interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Saw Superintendent positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini