Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Scaffold Erector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Scaffold Erector so you can tailor your answers to impress potential employers.

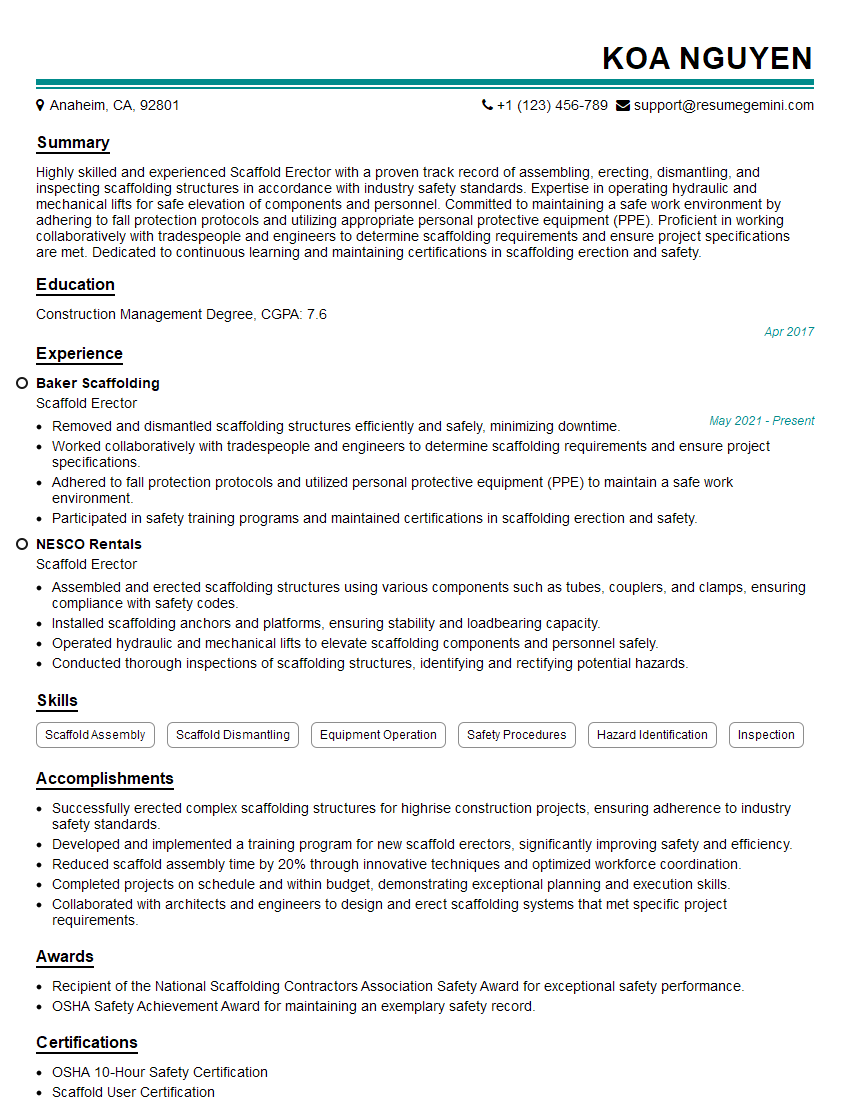

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scaffold Erector

1. Explain the different types of scaffolding systems you have worked with and their applications?

- Tube and coupler scaffolds: These are the most common type of scaffold, and they are made up of metal tubes and couplers. They are versatile and can be used for a variety of applications, including construction, maintenance, and repair.

- Frame scaffolds: These scaffolds are made up of prefabricated frames, which are then assembled on site. They are strong and durable, and they can be used for a variety of applications, including construction, maintenance, and repair.

- System scaffolds: These scaffolds are made up of modular components, which can be assembled in a variety of configurations. They are versatile and easy to erect, and they can be used for a variety of applications, including construction, maintenance, and repair.

- Suspended scaffolds: These scaffolds are suspended from a structure, and they are used for working at heights. They are safe and efficient, and they can be used for a variety of applications, including construction, maintenance, and repair.

2. Describe the safety regulations and best practices that you follow when erecting scaffolding?

Safety regulations

- Always wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and sturdy shoes.

- Inspect the scaffolding before each use to make sure it is in good condition.

- Do not overload the scaffolding.

- Do not work on scaffolding during bad weather, such as high winds or rain.

- Be aware of your surroundings and be careful not to bump into anything or anyone.

Best practices

- Use the proper tools and equipment for the job.

- Follow the manufacturer’s instructions for erecting and dismantling the scaffolding.

- Work with a partner or team to ensure safety.

- Take breaks as needed to avoid fatigue.

3. How do you ensure the stability and safety of scaffolding structures?

- By using the proper materials and equipment.

- By following the manufacturer’s instructions for erecting and dismantling the scaffolding.

- By inspecting the scaffolding before each use to make sure it is in good condition.

- By using proper bracing and tie-ins.

- By avoiding overloading the scaffolding.

- By working with a partner or team to ensure safety.

4. Describe the different types of loads that scaffolding can support and how you calculate the load capacity of a scaffold?

- Dead loads: These are the loads that are constantly applied to the scaffolding, such as the weight of the scaffold itself, the weight of the workers, and the weight of the materials being used.

- Live loads: These are the loads that are applied to the scaffolding for a short period of time, such as the weight of workers moving around or the weight of materials being lifted.

- Wind loads: These are the loads that are applied to the scaffolding by the wind.

- Snow loads: These are the loads that are applied to the scaffolding by the snow. To calculate the load capacity of a scaffold, you need to add up all of the dead loads, live loads, wind loads, and snow loads. The total load should not exceed the capacity of the scaffold.

5. How do you inspect scaffolding to ensure it is safe for use?

- Visual inspection: This involves looking at the scaffolding to check for any damage or defects.

- Load test: This involves applying a load to the scaffolding to test its strength and stability.

- Tagging: This involves placing a tag on the scaffolding to indicate that it has been inspected and is safe for use.

6. What are the common hazards associated with scaffolding and how do you mitigate them?

- Falls: This is the most common hazard associated with scaffolding. It can be mitigated by using proper fall protection equipment, such as harnesses and lanyards.

- Collapse: This can be caused by overloading the scaffolding, using damaged or defective materials, or not properly erecting the scaffolding. It can be mitigated by following the manufacturer’s instructions for erecting and dismantling the scaffolding and by using proper bracing and tie-ins.

- Electrocution: This can be caused by contact with electrical wires. It can be mitigated by being aware of the location of electrical wires and by using proper insulation.

- Struck-by: This can be caused by being struck by falling objects or materials. It can be mitigated by wearing proper head protection and by being aware of your surroundings.

7. What are the different methods of dismantling scaffolding and which method is most appropriate for a given situation?

- Top-down method: This involves dismantling the scaffolding from the top down. It is the most common method and it is used when the scaffolding is not too tall.

- Bottom-up method: This involves dismantling the scaffolding from the bottom up. It is used when the scaffolding is very tall.

- Combination method: This involves a combination of the top-down and bottom-up methods. It is used when the scaffolding is of moderate height. The best method for dismantling scaffolding depends on the height of the scaffolding and the situation.

8. What are the different types of scaffolding accessories and how are they used?

- Guardrails: These are used to protect workers from falls.

- Toe boards: These are used to prevent objects from falling off the scaffolding.

- Midrails: These are used to provide additional support for guardrails.

- Planks: These are used to provide a working surface for workers.

- Ladders: These are used to access the scaffolding.

- Braces: These are used to provide additional stability for the scaffolding.

- Tie-ins: These are used to connect the scaffolding to the structure it is being used on.

9. What are the different types of scaffolding training and certification programs available and which ones are most recognized in the industry?

- OSHA 30-hour Scaffolding Training: This is a basic training program that covers the OSHA scaffolding standards.

- OSHA 10-hour Scaffolding Training: This is a more advanced training program that covers the OSHA scaffolding standards in more depth.

- Certified Scaffold Erector (CSE): This is a certification program that is offered by the Scaffold Industry Association (SIA).

- Certified Scaffold Inspector (CSI): This is a certification program that is offered by the SIA. The most recognized scaffolding training and certification programs in the industry are the OSHA 30-hour Scaffolding Training and the Certified Scaffold Erector (CSE) program.

10. What are the career advancement opportunities for scaffold erectors?

- Foreman: A foreman is responsible for supervising a crew of scaffold erectors.

- Superintendent: A superintendent is responsible for managing a scaffolding company.

- Safety manager: A safety manager is responsible for developing and implementing safety programs for a scaffolding company.

- Trainer: A trainer is responsible for training scaffold erectors.

- Business owner: Some scaffold erectors start their own scaffolding companies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scaffold Erector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scaffold Erector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scaffold Erector positions require individuals to possess a range of specialized skills to ensure the safety and efficiency of construction projects involving scaffold systems. Their primary responsibilities include the assembly, alteration, maintenance, and dismantling of scaffolding structures. These structures provide safe access and work platforms for other tradespeople working at heights, ensuring their safety and enabling efficient project completion.

1. Scaffold Assembly

Assembling scaffolding involves adhering to blueprints and work orders to construct safe and stable structures. Scaffold erectors must follow industry standards and regulations to ensure the integrity of the scaffolding, which bears the weight of workers, materials, and equipment.

- Interpreting blueprints and work orders to determine the type and quantity of scaffolding required.

- Selecting and assembling the appropriate scaffolding components, such as poles, beams, braces, and platforms.

- Ensuring that all components are securely connected and properly aligned.

- Inspecting and testing the assembled scaffolding to ensure it meets safety standards.

2. Scaffold Alteration

As construction projects progress, changes may necessitate modifications to the scaffolding. Scaffold erectors must possess the adaptability to alter existing structures to accommodate new requirements while maintaining safety.

- Assessing the need for scaffold alterations based on changes in project scope or worksite conditions.

- Disassembling or relocating scaffold components as necessary to accommodate modifications.

- Reassembling and reinforcing the scaffolding to meet the new requirements.

- Ensuring that altered scaffolding complies with safety regulations and provides a safe work environment.

3. Scaffold Maintenance

Regular maintenance is crucial to ensure the ongoing safety and stability of scaffolding. Scaffold erectors are responsible for inspecting, cleaning, and repairing scaffold structures to identify and address any potential hazards.

- Conducting regular visual inspections of scaffolding to identify any damage or deterioration.

- Cleaning and removing debris from scaffolding surfaces to prevent slips and falls.

- Repairing or replacing damaged components promptly to maintain the integrity of the scaffolding.

- Applying rust-resistant coatings or treatments to protect the scaffolding from corrosion.

4. Scaffold Dismantling

Once construction work is complete, scaffolding must be safely dismantled. Scaffold erectors follow a systematic process to disassemble the structure without compromising safety.

- Disassembling the scaffolding in reverse order of assembly, ensuring stability throughout the process.

- Separating and storing scaffolding components for future use or disposal.

- Inspecting the worksite to ensure that no scaffolding materials or debris remain.

- Following proper waste disposal procedures for any discarded scaffolding components.

Interview Tips

Preparing for a Scaffold Erector interview requires a combination of technical knowledge and presentation skills. Candidates who take the time to research the industry, practice their answers, and demonstrate their enthusiasm for the role will increase their chances of making a positive impression.

1. Research the Industry

Familiarize yourself with the latest industry standards, safety regulations, and best practices related to scaffolding. Researching reputable sources, such as OSHA, ANSI, and industry publications, will demonstrate your knowledge and commitment to safety.

- Review OSHA regulations for scaffolding, including Subpart L of 29 CFR 1926.

- Study ANSI/ASSE A10.8 and ANSI/SIA A92.6 for comprehensive scaffolding safety guidelines.

- Stay up-to-date on industry trends and innovations by reading trade publications and attending industry events.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses that highlight your skills and experience. Practice delivering your answers clearly and concisely, using specific examples to support your points.

- Describe your experience in assembling, altering, maintaining, and dismantling scaffolding structures.

- Explain how you ensure the safety and stability of scaffolding systems.

- Provide examples of how you have dealt with challenges or unexpected situations on the job.

3. Demonstrate Your Enthusiasm

Conveying your passion for scaffolding and your commitment to safety will set you apart. Share examples of your dedication to professional development, such as obtaining certifications or attending training programs.

- Discuss your reasons for pursuing a career as a Scaffold Erector.

- Explain why you are passionate about safety and maintaining high standards in your work.

- Describe any personal or professional experiences that have reinforced your commitment to safety.

4. Prepare Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions that demonstrate your understanding of the role and the company’s values.

- Inquire about the company’s safety policies and procedures.

- Ask about the specific projects or clients that the company focuses on.

- Express your interest in opportunities for professional development and advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Scaffold Erector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Scaffold Erector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.