Feeling lost in a sea of interview questions? Landed that dream interview for Scale Clerk but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Scale Clerk interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

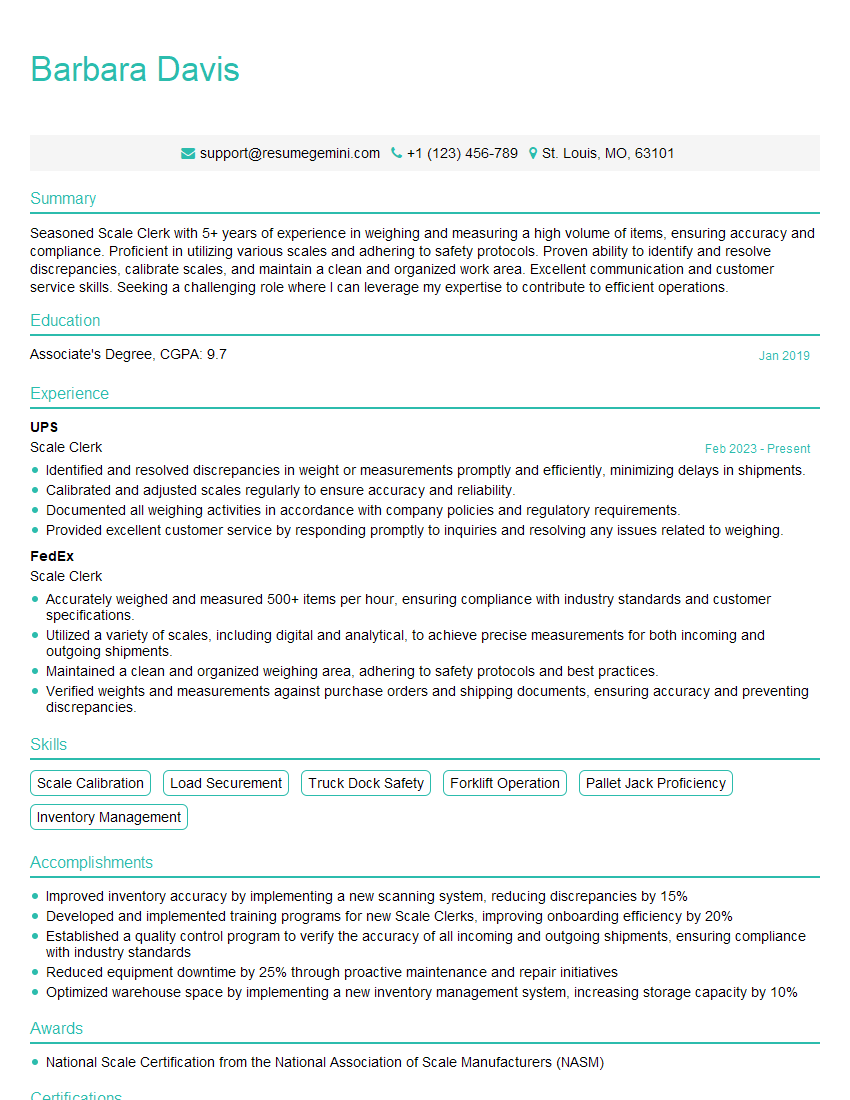

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scale Clerk

1. Explain the process of weighing and recording the weight of products?

The process of weighing and recording the weight of products involves several steps:

- Preparing the scale: Ensure the scale is calibrated, clean, and level.

- Placing the product on the scale: Carefully place the product on the center of the weighing platform.

- Reading the weight: Observe the weight displayed on the scale.

- Recording the weight: Write down the weight in the appropriate record, such as a logbook, invoice, or delivery note.

- Verifying the weight: Double-check the weight for accuracy by reweighing or using a different scale if necessary.

2. How do you ensure accuracy when measuring the weight of products?

Calibration

- Regularly calibrate the scale using certified weights.

- Follow the manufacturer’s calibration procedures.

Verification

- Verify the scale’s accuracy by weighing known weights.

- Cross-check measurements with a second scale.

Environmental factors

- Ensure the weighing area is free from vibrations and drafts.

- Consider temperature fluctuations that may affect the scale’s accuracy.

Proper handling

- Handle products and weighing equipment carefully to avoid damage.

- Clean the scale regularly to remove any debris or buildup.

Training and supervision

- Provide training to staff on proper weighing techniques.

- Supervise weighing operations to ensure compliance with procedures.

3. Describe the different types of scales used for weighing products and their applications?

- Mechanical scales: Use springs or levers to measure weight, suitable for basic weighing needs.

- Electronic scales: Utilize load cells to convert weight into an electrical signal, providing more precise measurements.

- Digital scales: Display weight digitally, offering ease of use and portability.

- Crane scales: Designed for weighing heavy loads suspended from a crane.

- Platform scales: Large platforms for weighing bulky or oversized items.

- Counting scales: Determine the number of pieces in a sample by weighing them.

- Checkweighers: Compare the weight of products to preset limits, ensuring accuracy.

4. How do you handle discrepancies in product weight and resolve them?

- Verify the discrepancy: Reweigh the product using the same scale or a different scale to confirm the discrepancy.

- Check the packaging: Inspect the packaging for any damage or leaks that may affect the weight.

- Review the product description: Ensure the expected weight matches the product being weighed.

- Calibrate the scale: Verify the scale’s calibration to rule out any errors.

- Document and report: Record the discrepancy and any corrective actions taken.

- Follow up: Monitor the situation to prevent similar discrepancies in the future.

5. How do you maintain and troubleshoot common issues with scales?

Maintenance

- Regular cleaning to remove debris and dust.

- Periodic calibration to ensure accuracy.

- Visual inspections for any damage or wear.

- Following manufacturer’s maintenance guidelines.

Troubleshooting

- Inaccurate readings: Check calibration, environmental factors, and proper use.

- Drifting readings: Verify stability, check for vibrations, and ensure the scale is level.

- Scale not responding: Inspect power supply, connections, and battery.

- Damaged scale: Contact the manufacturer for repair or replacement.

6. What safety precautions should be followed when using scales?

- Use the scale on a stable and level surface.

- Handle heavy objects carefully to prevent injury.

- Do not overload the scale beyond its capacity.

- Avoid placing hot objects directly on the weighing platform.

- Keep the scale clean and free from debris.

- Follow manufacturer’s safety instructions.

7. Explain how you would calibrate a scale?

Using calibration weights

- Gather certified calibration weights.

- Follow the manufacturer’s calibration procedure.

- Place the calibration weight on the scale and record the reading.

- Adjust the scale as per the instructions until it reads the correct weight.

Using a calibration kit

- Obtain a calibration kit specifically designed for the scale.

- Follow the instructions provided with the kit.

- Connect the kit to the scale and initiate the calibration process.

- Verify the scale’s accuracy by weighing known weights.

8. Describe the process of checking the zero point of a scale?

- Ensure the scale is empty.

- Press the “Zero” or “Tare” button.

- Verify that the scale displays zero or a very low reading.

- If necessary, adjust the zero point according to the manufacturer’s instructions.

- Re-check the zero point after placing a small object on the scale and then removing it.

9. How would you calculate the average weight of a set of products?

To calculate the average weight of a set of products:

- Weigh each product individually: Record the weight of each product in a set.

- Add the weights together: Sum up all the individual weights.

- Divide by the number of products: Determine the total number of products in the set.

- The result: The average weight is the sum divided by the number of products. For example, if you have 5 products with weights 10kg, 12kg, 8kg, 9kg, and 11kg, the average weight would be: (10 + 12 + 8 + 9 + 11) / 5 = 10kg

10. What techniques would you use to ensure the accuracy of your measurements?

- Calibrate the scale regularly.

- Check the zero point before each use.

- Handle the scale carefully to prevent damage.

- Use the appropriate scale for the weight range being measured.

- Read the weight carefully and record it accurately.

- Verify the weight by re-weighing or using a different scale.

- Follow the manufacturer’s instructions for use and maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scale Clerk.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scale Clerk‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Scale Clerk, you will play a vital role in ensuring accurate and efficient weighing and processing of materials at our organization. Your key responsibilities include:

1. Weighing and Recording Data

Operate scales to accurately weigh and record the weight of incoming and outgoing materials, ensuring compliance with established weight standards.

- Ensure precise measurements using appropriate scales and calibration procedures.

- Document weight data accurately in designated systems or logbooks.

2. Material Handling and Inspection

Handle materials and inspect them for any visible damage or discrepancies prior to weighing, verifying weight specifications against purchase orders or invoices.

- Communicate any discrepancies or damage to supervisors promptly.

- Maintain a clean and organized work area to ensure operational efficiency.

3. Equipment Maintenance and Calibration

Perform routine maintenance and calibration of weighing equipment to ensure accuracy and compliance with industry standards, following established protocols.

- Identify potential equipment malfunctions and report any issues promptly.

4. Inventory Management

Assist in inventory management by tracking material movements, maintaining inventory records, and verifying stock levels against weight records.

- Prepare and reconcile weight reports to support inventory audits and financial reconciliations.

Interview Tips

To ace your interview for the Scale Clerk position, consider the following tips and hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s background, values, and industry practices. This demonstrates your interest and knowledge of the field.

- Visit the company’s website and social media platforms.

- Read industry publications and articles to gain insights into current trends and best practices.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in weighing operations, equipment maintenance, and inventory management. Share specific examples that showcase your accuracy and efficiency.

- Quantify your accomplishments, using metrics or data to demonstrate your impact.

- Be prepared to discuss your experience in following industry regulations and safety protocols.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your qualifications. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Example question: Describe a time you faced a discrepancy in weighing data. How did you handle the situation?

4. Ask Insightful Questions

Prepare thoughtful questions to ask the interviewer. This shows your engagement and interest in the position and organization.

- Example question: Can you describe the company’s approach to quality control and accuracy in weighing operations?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Scale Clerk interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!