Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Scale Model Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Scale Model Maker so you can tailor your answers to impress potential employers.

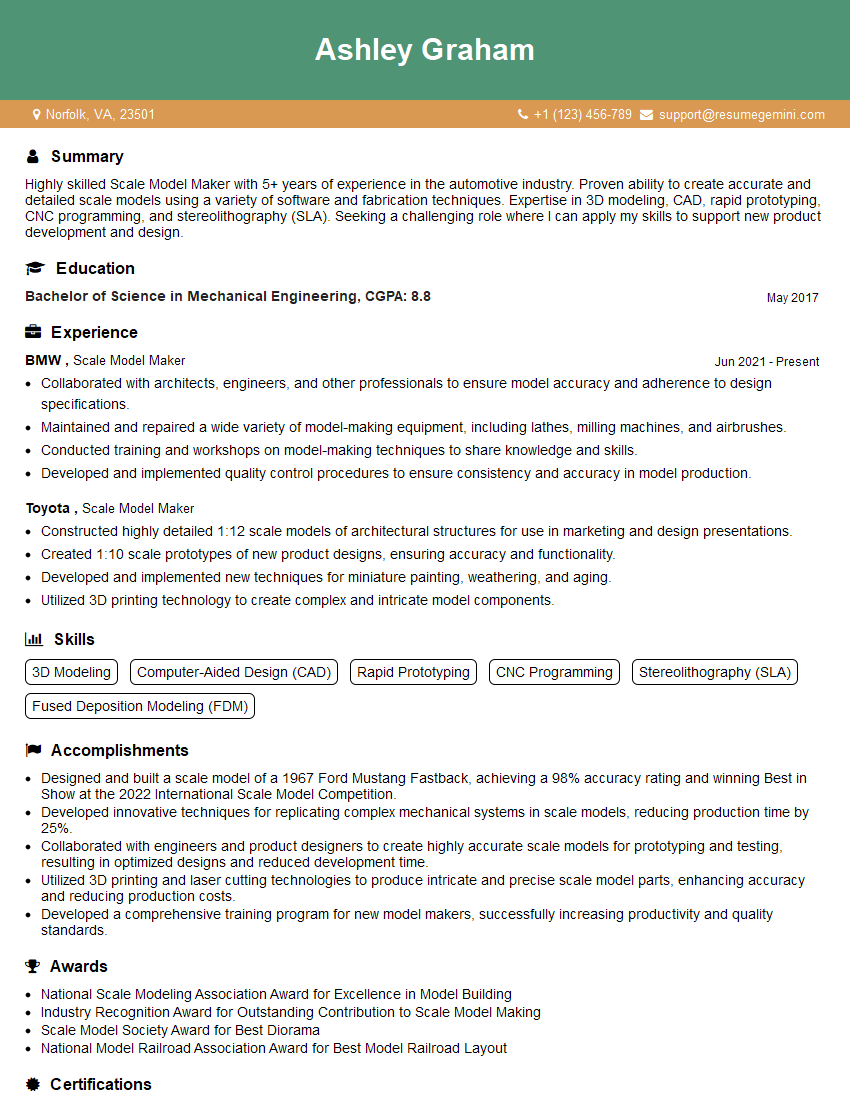

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scale Model Maker

1. What are the different types of scales used in scale modeling?

There are various types of scales used in scale modeling, including:

- Architectural scales: Used for architectural drawings and models, such as 1:50, 1:100, and 1:200.

- Metric scales: Based on the metric system, such as 1:10, 1:25, and 1:100.

- Imperial scales: Based on the imperial system, such as 1:12, 1:24, and 1:35.

- Railroad scales: Used for model trains and railroads, such as N scale (1:160), HO scale (1:87), and O scale (1:48).

- Plastic model scales: Commonly used for plastic model kits, such as 1:25, 1:32, and 1:48.

2. What are the key considerations when choosing the right materials for scale models?

When selecting materials for scale models, several key considerations must be taken into account:

- Accuracy: The materials should accurately represent the textures and characteristics of the real-life subject.

- Durability: The materials should be able to withstand handling, aging, and any potential environmental factors.

- Workability: The materials should be easy to cut, shape, and assemble.

- Availability: The materials should be readily available and cost-effective.

- Safety: The materials should not pose any health or environmental hazards.

3. What are the different techniques used to create realistic weathering effects on scale models?

Various techniques can be employed to achieve realistic weathering effects on scale models:

- Dry brushing: Applying dry paint with a brush to create subtle highlights and shadows.

- Washes: Using thinned paint to create streaks and stains, adding depth and realism.

- Chipping: Removing paint to simulate damage and wear.

- Fading: Exposing the model to sunlight or using paint to create the effect of fading.

- Rusting: Applying rust-colored pigments or paints to create the appearance of corrosion.

4. How do you ensure accuracy and precision in your scale models?

To ensure accuracy and precision in my scale models, I adhere to the following practices:

- Thorough research: Conducting extensive research on the subject of the model to ensure that all details are accurate.

- Use of blueprints and reference photos: Relying on detailed blueprints and high-quality reference photos for guidance.

- Precise measurements: Using precision measuring tools and calipers to ensure that dimensions are exact.

- Attention to detail: Paying meticulous attention to every detail of the model, including small and intricate features.

- Quality control: Regularly checking the model’s accuracy and precision throughout the building process.

5. Describe your experience with using different types of adhesives in scale modeling.

Cyanoacrylate Adhesives

- Excellent for bonding small and delicate parts quickly.

- Requires precise application and can produce fumes.

Epoxy Adhesives

- Strong and durable bond, ideal for large or heavy parts.

- Requires mixing and can have a longer curing time.

Polyurethane Adhesives

- Flexible and gap-filling, suitable for bonding dissimilar materials.

- Can expand during curing, so proper clamping is necessary.

6. How do you handle the assembly and painting of complex scale models?

When assembling and painting complex scale models, I follow these steps:

- Sub-assembly: Dividing the model into smaller, manageable sub-assemblies for easier handling.

- Dry-fitting: Test-fitting parts without glue to ensure proper fit and alignment.

- Gluing: Using appropriate adhesives and techniques to secure the parts securely.

- Priming: Applying a primer to provide a uniform surface for painting.

- Base coating: Applying a base coat of paint that matches the overall color scheme.

- Detail painting: Using fine brushes and techniques to add details, highlights, and weathering.

7. What are the best practices for storing and preserving scale models?

To ensure the longevity and preservation of scale models, I follow these best practices:

- Climate Control: Storing models in a controlled environment with stable temperature and humidity.

- Protection from Dust: Using display cases or boxes to protect models from dust and dirt.

- Avoid Direct Sunlight: Keeping models away from direct sunlight to prevent fading and damage.

- Handle with Care: Using gloves or clean hands when handling models to minimize risk of damage.

- Regular Inspection: Periodically inspecting models for any signs of wear or deterioration.

8. How do you stay updated on the latest techniques and materials used in scale modeling?

To stay updated on the latest techniques and materials, I take the following steps:

- Attend Workshops and Conventions: Participating in industry events to learn from experts and discover new products.

- Subscribe to Magazines and Journals: Reading publications dedicated to scale modeling for the latest news and articles.

- Follow Online Forums and Communities: Engaging with online communities to share knowledge and learn from others.

- Experiment with New Materials: Testing and experimenting with different materials and techniques to improve my skills.

9. What are your favorite scale modeling projects that you have worked on?

Some of my favorite scale modeling projects include:

- 1/35 scale Sherman tank: Creating a highly detailed model with intricate weathering and diorama setting.

- 1/24 scale Porsche 911: Building a realistic sports car model with custom paintwork and aftermarket parts.

- 1/72 scale aircraft carrier: Constructing a large and complex model with multiple components and intricate details.

10. How do you manage your time effectively when working on multiple scale modeling projects?

To manage my time effectively when working on multiple projects, I follow these strategies:

- Prioritizing Projects: Identifying the most important or urgent projects to focus on.

- Setting Realistic Deadlines: Establishing achievable deadlines to avoid overwhelming myself.

- Breaking Down Projects: Dividing large projects into smaller, manageable tasks.

- Scheduling Time Blocks: Allocating specific time slots for working on each project.

- Taking Breaks: Taking regular breaks to maintain focus and prevent burnout.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scale Model Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scale Model Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scale Model Makers are responsible for building and assembling scale models, often using a variety of materials and techniques. These models are used in a variety of industries, including architecture, engineering, and manufacturing. Some of the key responsibilities of a Scale Model Maker include:

1. Building and Assembling Models

Scale Model Makers are responsible for building and assembling scale models of objects, such as buildings, vehicles, and aircraft. They use a variety of materials and techniques to create these models, including wood, plastic, metal, and clay.

- Using blueprints and drawings to create accurate models

- Selecting and using the appropriate materials and techniques for each model

- Assembling models with precision and accuracy

2. Detailing and Finishing Models

Once the models are assembled, Scale Model Makers are responsible for detailing and finishing them. This may involve adding paint, decals, and other details to make the models more realistic. They also need to ensure that the models are durable and can withstand handling and display.

- Painting models to create realistic finishes

- Adding decals and other details to enhance realism

- Applying protective coatings to models to ensure durability

3. Maintaining Equipment and Tools

Scale Model Makers also need to maintain their equipment and tools. This may involve cleaning and calibrating tools, as well as replacing parts as needed. They also need to keep their work area clean and organized in order to ensure safety and efficiency.

- Cleaning and calibrating tools and equipment

- Replacing parts as needed

- Maintaining a clean and organized work area

4. Following Safety Procedures

Scale Model Makers need to follow safety procedures in order to protect themselves and others from injury. This may involve wearing personal protective equipment, such as gloves and safety glasses, and using tools and equipment properly. They also need to be aware of the hazards associated with working with different materials and chemicals.

- Wearing personal protective equipment

- Using tools and equipment properly

- Being aware of the hazards associated with working with different materials and chemicals

Interview Tips

Preparing for an interview for a Scale Model Maker position can be daunting, but there are several things you can do to increase your chances of success.

1. Research the Company and Position

Before the interview, take the time to research the company and the position you’re applying for. This will help you understand the company’s culture, the specific requirements of the position, and the types of questions you’re likely to be asked.

- Visit the company’s website

- Read the job description carefully

- Look for news articles and press releases about the company

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method (Situation, Task, Action, Result) to answer questions

- Highlight your skills and experience that are relevant to the position

- Be prepared to talk about your portfolio and any relevant projects you’ve worked on

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of the interview shows that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture and values

- Ask about the specific responsibilities of the position

- Ask about the company’s plans for the future

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you respect their time and that you’re serious about the position.

- Wear clean, pressed clothes

- Arrive 10-15 minutes early for your interview

- Bring a portfolio or examples of your work to show the interviewer

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Scale Model Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Scale Model Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.