Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Scale Shooter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

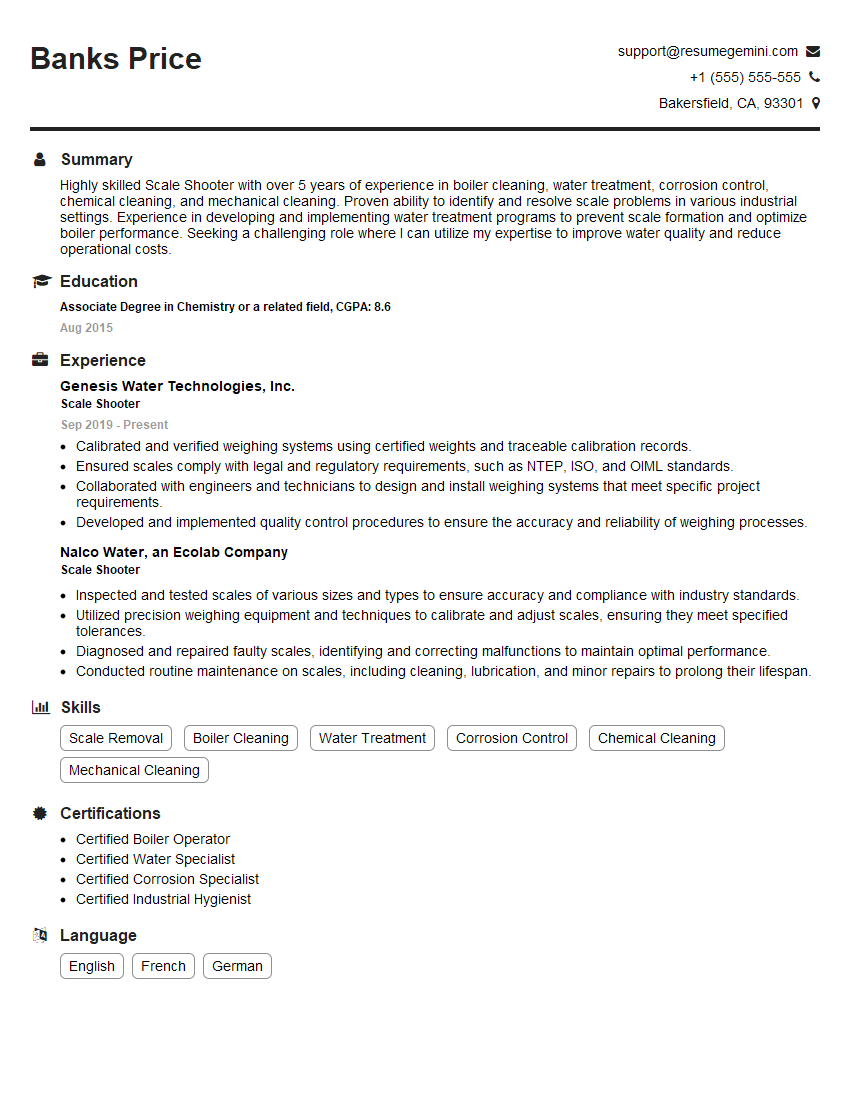

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scale Shooter

1. Describe your experience with using different types of scale equipment?

– Experience with a variety of scale equipment, including digital scales, mechanical scales, and bench scales – Knowledge of the different features and benefits of each type of scale – Ability to calibrate and maintain scales according to manufacturer’s specifications

2. How do you ensure that the scales you use are accurate and calibrated?

Calibration Procedure

- Follow manufacturer’s calibration instructions

- Use certified weights to calibrate the scale

- Document the calibration process

Accuracy Checks

- Regularly check the scale’s accuracy using known weights

- Investigate any discrepancies and make necessary adjustments

3. What are the different types of scales used in industrial settings, and what are their specific applications?

- Bench Scales: Used for weighing small objects, typically up to 500 lbs

- Floor Scales: Used for weighing large objects, typically over 500 lbs

- Crane Scales: Used for weighing suspended loads

- Conveyor Scales: Used for weighing materials on a conveyor belt

- Tank and Hopper Scales: Used for weighing liquids and solids in tanks and hoppers

4. What are the safety precautions that must be taken when using scales?

- Ensure that the scale is properly calibrated and maintained

- Do not overload the scale

- Handle heavy objects carefully

- Wear appropriate safety gear

- Follow all manufacturer’s instructions

5. What are some common problems you have encountered with scales and how did you resolve them?

- Inaccurate readings: Calibrate the scale or check for faulty components

- Overloading: Reduce the weight on the scale or use a larger scale

- Mechanical failures: Contact the manufacturer or a qualified technician

- Electrical problems: Check power supply and connections or contact an electrician

6. How do you stay up-to-date on the latest advancements in scale technology?

- Attend industry conferences and workshops

- Read trade publications and online resources

- Network with other scale professionals

7. What is your understanding of scale calibration, and why is it important?

Calibration

- Adjusting a scale to ensure its accuracy

- Involves using certified weights to set the scale’s zero point and sensitivity

Importance

- Ensures accurate weighing results

- Complies with industry regulations and quality standards

- Prevents costly errors and product loss

8. How do you troubleshoot a scale that is not functioning properly?

- Check power supply: Ensure the scale is connected to a power source

- Inspect connections: Verify that all electrical connections are secure

- Check load cell: Examine the load cell for any damage or loose connections

- Calibrate the scale: Recalibrate the scale using certified weights

- Contact the manufacturer or a qualified technician: If the issue persists, contact a professional for assistance

9. What are the different types of scale indicators, and what are their advantages and disadvantages?

- Mechanical Indicators: Analog dials, easy to read, limited functionality

- Digital Indicators: Electronic displays, precise, versatile

- Remote Indicators: Wireless or wired, allow viewing from a distance

10. Describe your experience with scale maintenance and repair.

- Regular cleaning and inspection of scales

- Replacement of worn or damaged parts

- Calibration and adjustment of scales as needed

- Troubleshooting and resolving scale malfunctions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scale Shooter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scale Shooter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scale Shooters are responsible for removing scale buildup from equipment and surfaces within industrial settings, typically in power plants and manufacturing facilities.

1. Scale Removal

The primary responsibility of a Scale Shooter is to remove scale buildup from various equipment and surfaces. Scale, which is a hard mineral deposit, can accumulate on heat exchangers, boilers, condensers, pumps, and piping.

- Use high-pressure water jets, chemical cleaning agents, and mechanical tools to remove scale buildup.

- Operate specialized equipment, such as hydro-blasting units and descaling machines.

- Ensure proper disposal of removed scale.

2. Equipment Maintenance

In addition to scale removal, Scale Shooters are often responsible for maintaining the equipment they use.

- Inspect and clean equipment regularly to prevent scale buildup.

- Perform minor repairs and adjustments to equipment as needed.

- Maintain accurate records of equipment maintenance and repairs.

3. Safety and Compliance

Scale Shooters must adhere to strict safety protocols and industry regulations to ensure their own safety and the safety of others.

- Wear appropriate personal protective equipment (PPE), including respirators, gloves, and safety glasses.

- Follow established safety procedures for handling chemicals and operating equipment.

- Stay informed about industry regulations and best practices.

4. Communication and Teamwork

Scale Shooters often work as part of a team and must be able to communicate effectively with other team members as well as with supervisors and clients.

- Communicate with supervisors to discuss work assignments and progress.

- Collaborate with other team members to ensure efficient and effective scale removal.

- Provide clear and concise reports to clients on the status of scale removal projects.

Interview Tips

To ace an interview for a Scale Shooter position, candidates should be prepared to demonstrate their skills and experience in scale removal, equipment maintenance, and safety compliance.

1. Research the Company and Industry

Familiarize yourself with the company you are applying to, its industry, and the specific requirements of the Scale Shooter role. This will help you understand the company’s needs and tailor your answers accordingly.

- Visit the company’s website to learn about their business, values, and recent projects.

- Research the industry to understand the common challenges and best practices in scale removal.

- Review the job description carefully to identify the key skills and qualifications required for the position.

2. Highlight Your Skills and Experience

Emphasize your skills and experience in scale removal, equipment maintenance, and safety compliance. Use specific examples from your past work experience to demonstrate your abilities.

- Quantify your accomplishments whenever possible. For example, instead of saying “I removed scale buildup from equipment,” say “I removed over 100 tons of scale buildup from equipment in a single year, resulting in a significant increase in equipment efficiency.”

- Be prepared to discuss your experience with different types of scale removal equipment and chemical cleaning agents.

3. Emphasize Safety and Compliance

Safety is paramount in the role of a Scale Shooter. Highlight your understanding of industry regulations and your commitment to following safe work practices.

- Describe your experience in wearing and maintaining PPE.

- Discuss your knowledge of lockout/tagout procedures.

- Explain how you stay informed about industry regulations and best practices.

4. Practice Your Communication Skills

Scale Shooters must be able to communicate effectively with a variety of stakeholders. Practice your communication skills by rehearsing your answers to common interview questions.

- Prepare an elevator pitch that summarizes your skills and experience.

- Practice answering questions about your experience with different types of scale removal equipment.

- Rehearse your responses to questions about safety and compliance.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Scale Shooter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Scale Shooter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.