Are you gearing up for an interview for a Scalper Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Scalper Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

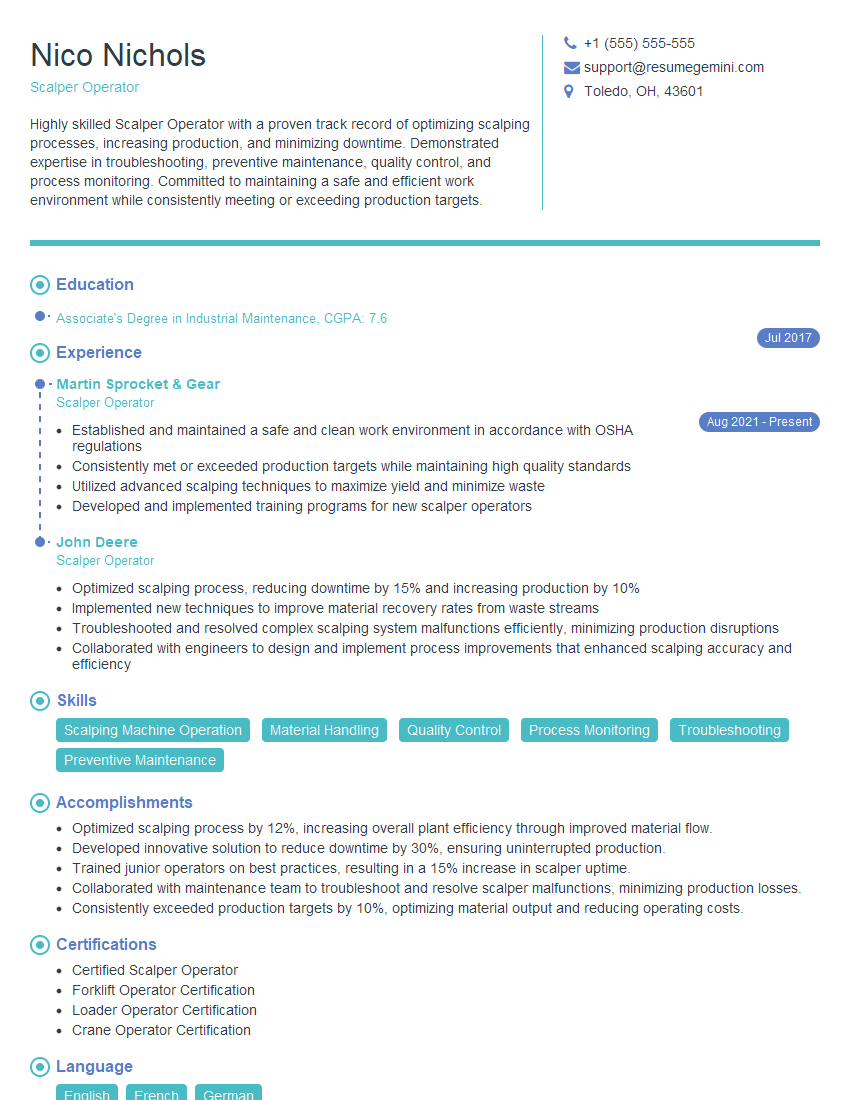

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scalper Operator

1. How do you calibrate the scalper blades to ensure accurate cuts?

To calibrate the scalper blades accurately, I follow these steps:

- Check for any loose or worn components.

- Set the blade gap using feeler gauges or a digital caliper.

- Align the blades and make sure they are parallel to each other.

- Run a test cut on a scrap piece to verify accuracy.

- Fine-tune the calibration as needed based on the desired cut quality.

2. Explain the factors that affect the scalper’s cutting efficiency.

The scalper’s cutting efficiency is influenced by several factors, including:

- Blade sharpness: Dull blades result in poor cutting quality.

- Blade gap: The gap between the blades affects the thickness of the cut.

- Feed rate: The speed at which the material is fed through the scalper.

- Material type: Different materials have varying hardness and require different blade types.

- Blade alignment: Misaligned blades can cause uneven cuts.

3. How do you handle scalper malfunctions or breakdowns?

When faced with a scalper malfunction or breakdown, I take the following actions:

- Safety first: Ensure the machine is powered off and lockout/tagout procedures are followed.

- Identify the issue: Inspect the scalper for any obvious damage or loose components.

- Troubleshoot the problem: Use technical documentation or consult with experienced personnel to diagnose the issue.

- Repair or replace: Perform necessary repairs or replace faulty parts following manufacturer’s guidelines.

- Test and verify: Run a test cut to ensure the scalper is functioning properly after repairs.

4. Describe how you optimize the scalper settings for different material thicknesses.

To optimize the scalper settings for varying material thicknesses, I follow these steps:

- Blade gap adjustment: Adjust the blade gap according to the desired cut thickness.

- Feed rate modification: Set the feed rate to match the material thickness to achieve efficient cutting.

- Blade angle adjustment: For thick materials, slightly inclining the blades can improve cutting performance.

- Blade selection: Use appropriate blade types designed for cutting specific material thicknesses.

- Test and refinement: Run пробны cuts to fine-tune the settings and ensure optimal cutting quality.

5. How do you work with downstream equipment, such as conveyors or other processing machines, to ensure smooth operation?

To ensure smooth collaboration with downstream equipment, i take the following measures:

- Communication: I communicate with operators of downstream equipment to establish clear expectations.

- Flow optimization: I adjust the scalper’s output to match the capacity of downstream equipment.

- Material handling: I ensure proper material transfer to prevent interruptions.

- Maintenance coordination: I schedule maintenance activities of the scalper and downstream equipment simultaneously to minimize downtime.

- Problem-solving: I collaborate with other operators to quickly resolve any issues that may arise.

6. How do you ensure the safety of yourself and others while operating the scalper?

To prioritize safety during scalper operation, I adhere to the following measures:

- Proper training: I have received comprehensive training on the safe operation of the scalper.

- PPE usage: I wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Lockout/tagout procedures: I follow established procedures to isolate the scalper during maintenance or repairs.

- Material handling: I use proper techniques to lift and handle materials, preventing injuries.

- Emergency preparedness: I am familiar with emergency protocols and know how to respond to potential hazards.

7. Describe your experience in maintaining and inspecting the scalper to identify potential issues.

I have extensive experience in maintaining and inspecting scalpers to proactively identify potential issues. My maintenance routine includes:

- Regular inspections: I perform daily inspections to check for any loose parts, worn components, or signs of damage.

- Blade sharpening: I sharpen or replace the scalper blades regularly to ensure optimal cutting performance.

- Lubrication: I lubricate moving parts according to the manufacturer’s specifications to prevent wear and tear.

- Alignment checks: I check and adjust the alignment of the blades and other components as needed.

- Documentation: I maintain a detailed maintenance log to record inspections, repairs, and any potential issues identified.

8. How do you stay up-to-date with advancements in scalper technology and industry best practices?

To stay abreast of advancements in scalper technology and industry best practices, I engage in the following activities:

- Industry events: I attend industry conferences, exhibitions, and workshops to learn about new technologies.

- Technical publications: I read trade magazines and journals to stay informed about the latest industry trends.

- Manufacturer updates: I subscribe to manufacturer newsletters and attend webinars to learn about product updates and best practices.

- Networking: I connect with other scalper operators and industry professionals to exchange knowledge and experiences.

- Continuous learning: I actively seek opportunities for professional development and training to enhance my skills.

9. Explain how you would improve the efficiency of a scalping operation in a given scenario.

To improve the efficiency of a scalping operation in a given scenario, I would consider the following strategies:

- Process optimization: Analyze the current scalping process and identify areas for improvement, such as reducing material handling time or optimizing feed rates.

- Equipment enhancements: Evaluate the possibility of upgrading or retrofitting the scalper with newer technologies that can enhance productivity.

- Workflow integration: Explore opportunities to integrate the scalper with other equipment or processes to create a more streamlined operation.

- Personnel training: Provide additional training to operators on best practices for scalper operation to improve efficiency and reduce downtime.

- Data analysis: Collect and analyze data from the scalping process to identify trends and areas for improvement.

10. Describe your approach to troubleshooting and resolving scalper-related quality issues.

My approach to troubleshooting and resolving scalper-related quality issues involves the following steps:

- Problem identification: I carefully inspect the material produced by the scalper to identify specific quality defects.

- Cause analysis: I examine the scalper and its components, including blades, settings, and materials, to determine the potential causes of the defects.

- Solution implementation: Based on the identified cause, I make necessary adjustments to the scalper’s settings, maintenance schedule, or operating procedures.

- Verification: I run test cuts to verify that the quality issue has been resolved and the scalper is producing material within acceptable specifications.

- Continuous improvement: I document the troubleshooting process and share lessons learned to prevent similar issues in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scalper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scalper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scalper Operators perform a crucial role in manufacturing processes, primarily in the paper industry. Their responsibilities encompass a wide range of tasks necessary for the efficient and safe operation of scalping equipment.

1. Scalping Operation

Operate scalping equipment to remove oversized particles, contaminants, and impurities from raw materials.

- Control the flow of material through the scalping screen.

- Monitor and adjust machine settings to optimize separation efficiency.

2. Material Handling

Handle raw materials and finished products, ensuring proper storage and handling.

- Load and unload raw materials from designated areas.

- Transport finished products to designated storage areas.

3. Equipment Maintenance

Perform routine maintenance and minor repairs on scalping equipment.

- Inspect and clean equipment regularly.

- Troubleshoot and resolve minor malfunctions.

4. Safety and Compliance

Adhere to all safety regulations and procedures related to scalping operations.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips

To prepare for an interview for a Scalper Operator position, the following tips and strategies can be highly beneficial.

1. Research the Company and Industry

Familiarize yourself with the company’s profile, their products or services, and the specific industry they operate in. This knowledge will enable you to speak intelligently about your understanding of the industry and its trends.

- Visit the company’s website to gain insights into their operations and areas of expertise.

- Read industry-specific publications and articles to stay updated on the latest advancements and best practices.

2. Practice Your Responses to Common Interview Questions

Prepare thoughtful and concise answers to common interview questions related to your skills, experience, and motivations. Anticipating potential questions will boost your confidence and allow you to present yourself effectively.

- Prepare examples to demonstrate your abilities in material handling, equipment maintenance, and safety compliance.

- Explain your understanding of scalping equipment and its role in the manufacturing process.

3. Highlight Your Safety Commitment

Emphasize your commitment to safety and your understanding of the safety protocols and regulations in the manufacturing industry. This is a crucial aspect for Scalper Operators, and demonstrating your dedication to safety will set you apart.

- Share examples of how you have implemented safety measures in previous roles.

- Express your willingness to actively participate in safety initiatives and training programs.

4. Ask Informed Questions

During the interview, ask thoughtful questions to demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more about the opportunity.

- Inquire about the company’s growth plans and future projects.

- Ask about the potential for professional development and advancement within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Scalper Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.