Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Scalping Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

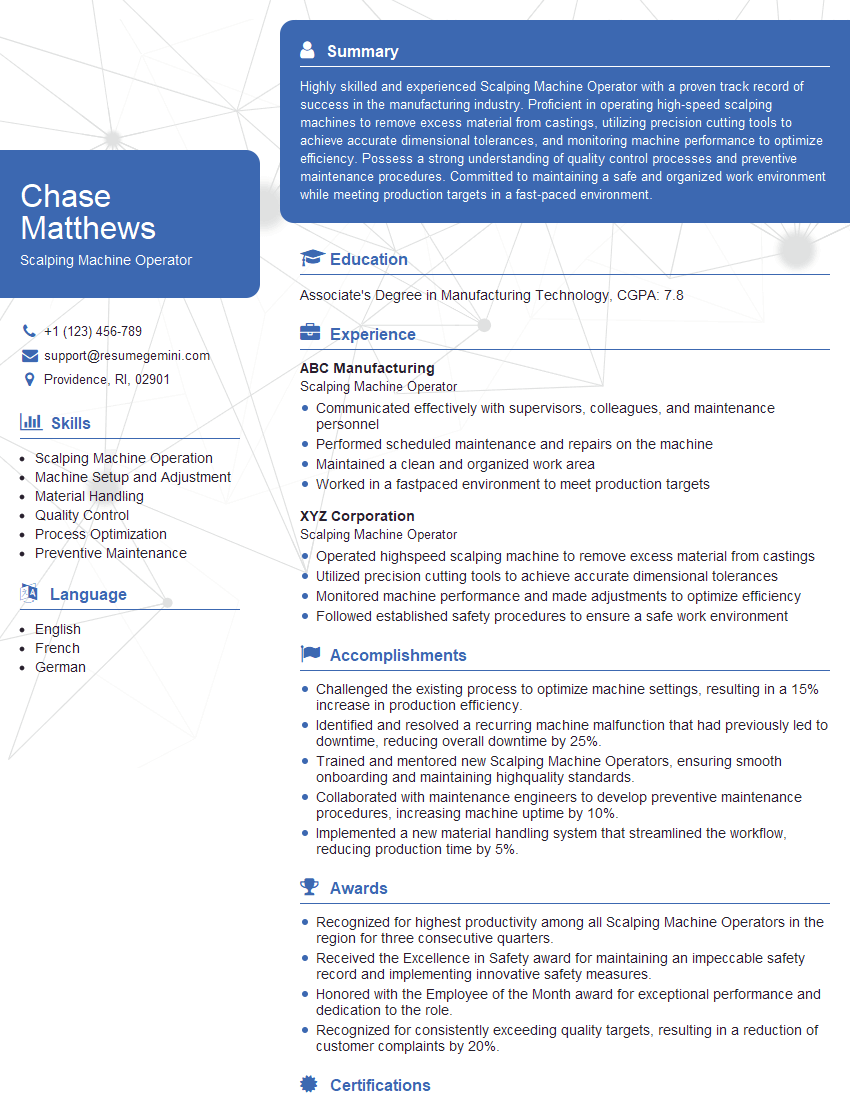

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scalping Machine Operator

1. How do you ensure the accuracy and precision of the scalping machine?

- Regularly calibrate the machine according to manufacturer specifications.

- Use precise cutting tools and blades.

- Visually inspect the machine and its components for any signs of wear or damage.

2. Describe the different types of scalping machines and their applications.

- Single-head scalpers: Used for light-duty scalping, such as removing the surface layer of wood or plastic.

- Multi-head scalpers: Used for heavy-duty scalping, such as removing bark from logs or large pieces of wood.

- Rotary scalpers: Used for precision scalping, such as creating smooth surfaces on metal or plastic parts.

3. What are the safety protocols you follow when operating a scalping machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure the machine is properly grounded and in good working order before starting it.

- Never place your hands or other body parts near the cutting blade while the machine is in operation.

- Keep the work area clear of debris and obstacles.

4. How do you troubleshoot common problems that may arise while operating a scalping machine?

- Machine not starting: Check the power source, wiring, and fuses.

- Inaccurate cutting: Check the cutting tool for sharpness and alignment.

- Excessive vibration: Check the machine’s balance and ensure it is properly mounted.

- Overheating: Allow the machine to cool down and check for any blockages or obstructions.

5. What is the importance of maintaining a clean and well-lubricated scalping machine?

- Reduces wear and tear on the machine’s components.

- Improves the accuracy and precision of the cutting process.

- Extends the lifespan of the machine.

- Prevents the buildup of sawdust and debris, which can cause overheating and other problems.

6. How do you calculate the cutting speed and feed rate for different types of materials being scalped?

- Refer to manufacturer’s specifications for recommended cutting speeds and feed rates.

- Consider the material’s hardness, thickness, and desired finish.

- Make adjustments to the cutting speed and feed rate based on the machine’s capabilities.

- Use a trial-and-error approach to determine the optimal settings for each material.

7. What are the different blade types used in scalping machines and how do you select the appropriate blade for the job?

- High-speed steel (HSS) blades: Used for cutting softer materials, such as wood, plastic, and rubber.

- Carbide-tipped blades: Used for cutting harder materials, such as metal and concrete.

- Diamond-tipped blades: Used for cutting very hard materials, such as ceramics and stone.

- Select the blade based on the material being cut, the desired finish, and the cutting speed required.

8. How do you handle and store scalping machine blades to ensure their longevity and sharpness?

- Store the blades in a dry and protected place when not in use.

- Use blade covers or sheaths to protect the blades from damage.

- Clean the blades regularly to remove sawdust and debris.

- Sharpen the blades periodically to maintain their cutting edge.

9. What is the role of coolant in scalping operations and how do you select the appropriate coolant for different materials?

- Coolant reduces heat and friction during the cutting process.

- It improves the tool’s life and the surface finish of the workpiece.

- Select the coolant based on the material being cut, the cutting speed, and the desired finish.

- Common coolants include water-based solutions, oil-based solutions, and synthetic coolants.

10. How do you determine the proper depth of cut for a scalping operation?

- Consider the material thickness and the desired finish.

- Start with a shallow cut and gradually increase the depth until the desired result is achieved.

- Use a depth gauge or other measuring tool to ensure accurate cutting.

- Avoid excessive cutting depth, as this can damage the material or the scalping machine.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scalping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scalping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Scalping Machine Operator is responsible for operating and maintaining a scalping machine, a device that removes the outermost layer of a product, such as fruits, vegetables, or wood. This role plays a crucial part in the production process and requires proficiency in machinery operation, safety protocols, and quality control.

1. Machine Operation and Maintenance

Operate the scalping machine efficiently, ensuring smooth and consistent production.

- Set up and calibrate the machine according to product specifications and process requirements.

- Monitor machine operation, make adjustments, and perform routine maintenance to prevent breakdowns.

2. Product Handling and Quality Control

Inspect incoming raw materials and ensure they meet quality standards.

- Remove impurities, foreign objects, and damaged products from the product stream.

- Maintain high levels of product quality by adhering to established specifications and process guidelines.

3. Productivity and Efficiency

Maximize productivity by optimizing machine settings and minimizing downtime.

- Follow established production schedules and targets, ensuring timely delivery of products.

- Identify and implement process improvements to enhance efficiency and reduce waste.

4. Safety and Compliance

Adhere to all safety regulations and guidelines.

- Wear appropriate safety gear and follow established safety protocols.

- Maintain a clean and organized work area to prevent accidents and ensure compliance.

Interview Tips

To ace an interview for a Scalping Machine Operator position, it’s crucial to prepare thoroughly and showcase your skills and qualifications. Here are some tips to help you succeed:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and operations. Research the specific role and its responsibilities to demonstrate your interest and knowledge.

- Visit the company website and social media pages to gather information about their culture and values.

- Review industry publications and articles to stay updated on relevant trends and technologies.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses that highlight your skills and experience. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Example Outline: Tell me about a time when you had to troubleshoot a problem with a machine.

Situation: Describe the situation and the problem you encountered. Task: Explain the steps you took to diagnose the issue. Action: Discuss the specific actions you performed to resolve the problem. Result: Quantify the outcome of your actions and emphasize the positive impact.

3. Emphasize Safety and Quality Control

In this role, safety and quality control are paramount. Highlight your commitment to adhering to safety protocols and maintaining high product quality.

- Provide examples of how you have implemented safety measures in previous roles.

- Explain how you ensure product quality by monitoring and inspecting products throughout the process.

4. Be Punctual and Professional

Punctuality and professionalism are highly valued in industrial settings. Arrive on time for your interview and dress appropriately.

- Show enthusiasm and a positive attitude during the interview.

- Be respectful of the interviewer’s time and ask thoughtful questions to demonstrate your interest.

Next Step:

Now that you’re armed with the knowledge of Scalping Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Scalping Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini