Are you gearing up for an interview for a Scrap Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Scrap Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

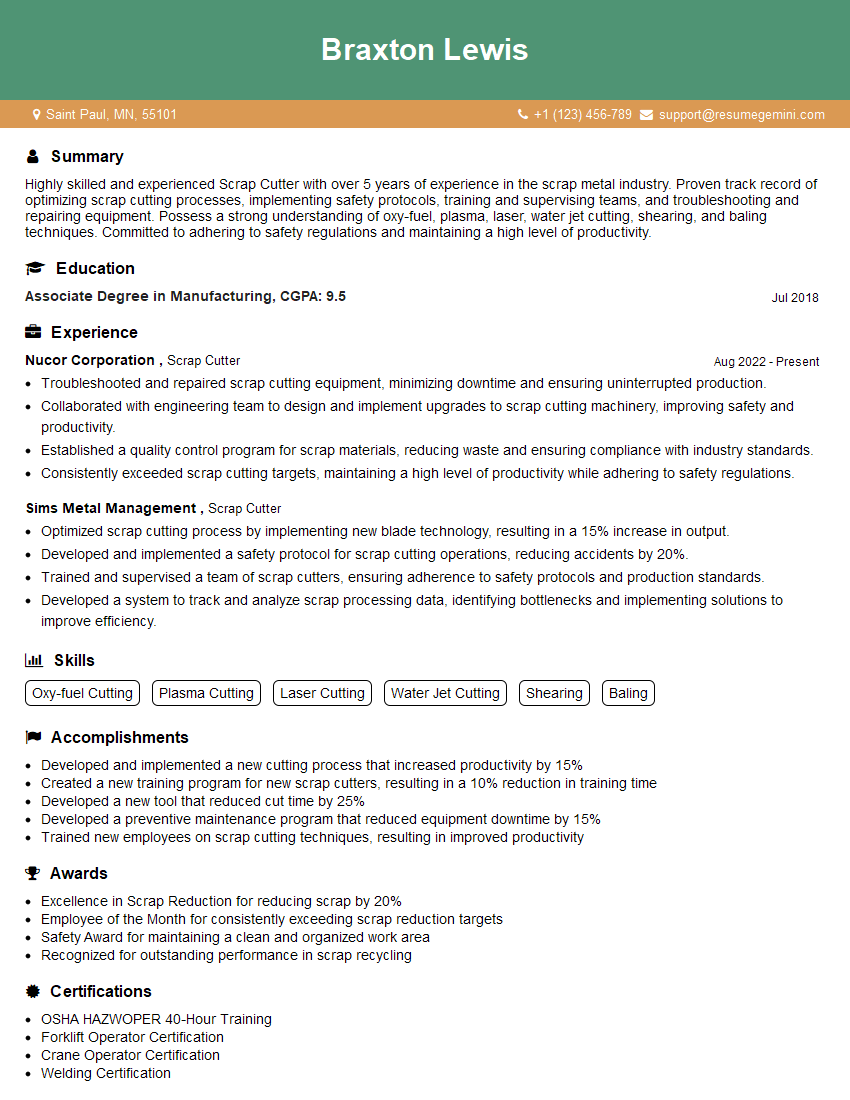

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scrap Cutter

1. What are the different types of scrap materials that you are familiar with?

In my previous role, I’ve worked with a wide range of scrap materials, including ferrous and non-ferrous metals, plastics, paper, and cardboard.

2. What is the importance of segregating different types of scrap materials?

Benefits of Segregation:

- Increased revenue potential: Different scrap materials have different values, and segregating them allows for more accurate pricing and higher returns.

- Reduced contamination: Mixing different types of scrap can contaminate the materials, reducing their value or making them unusable.

- Improved safety: Segregating hazardous materials, such as batteries or chemicals, ensures proper handling and disposal.

Methods of Segregation:

- Visual inspection: Identifying different materials based on their appearance.

- Magnetic separation: Using magnets to separate ferrous metals from non-ferrous metals.

- Density separation: Using liquids or air streams to separate materials based on their density.

3. What are the safety precautions that should be taken when handling scrap materials?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and respirators when necessary.

- Be aware of sharp edges and protruding objects.

- Follow proper lifting techniques to avoid injuries.

- Handle hazardous materials with care and dispose of them properly.

- Maintain a clean and organized work area.

4. What is the process of scrap metal recycling?

- Collection: Scrap metal is collected from various sources, such as junkyards, demolition sites, and manufacturing facilities.

- Processing: The scrap metal is sorted, shredded, and processed to remove contaminants and prepare it for recycling.

- Melting: The processed scrap metal is melted in a furnace to remove impurities and create molten metal.

- Refining: The molten metal is refined to remove any remaining impurities and produce high-quality metal.

- Manufacturing: The refined metal is used to manufacture new products, such as steel beams, car parts, and appliances.

5. What are the different types of scrap metal cutting equipment?

- Shear: A shear uses a blade to cut scrap metal into smaller pieces.

- Baler: A baler compresses scrap metal into bales for easier handling and transportation.

- Torch: A torch uses a high-temperature flame to cut through thick metal.

- Plasma cutter: A plasma cutter uses a plasma arc to cut through metal.

- Water jet cutter: A water jet cutter uses a high-pressure stream of water to cut through metal.

6. What are the factors to consider when selecting scrap metal cutting equipment?

- Type of scrap metal to be cut

- Thickness of the scrap metal

- Volume of scrap metal to be cut

- Budget

- Space availability

7. How do you maintain scrap metal cutting equipment?

- Regular cleaning and inspection

- Lubrication of moving parts

- Replacement of worn or damaged parts

- Calibration and adjustment as needed

- Following manufacturer’s maintenance guidelines

8. What are the challenges faced in scrap metal cutting?

- Dealing with sharp edges and heavy materials

- Ensuring safety and following proper procedures

- Optimizing cutting efficiency for different types of scrap metal

- Maintaining equipment and ensuring smooth operations

- Staying updated with industry best practices and regulations

9. How do you stay updated with the latest advancements in scrap metal cutting technology?

- Attending industry conferences and exhibitions

- Reading trade publications and technical articles

- Networking with other professionals in the field

- Seeking training and certifications from manufacturers

- Exploring online resources and forums

10. How do you ensure quality control in your scrap metal cutting work?

- Establishing clear cutting standards and specifications

- Regularly inspecting cut materials to meet quality requirements

- Calibrating and maintaining cutting equipment to ensure precision

- Documenting cutting processes and results for traceability

- Implementing quality control measures throughout the cutting operation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scrap Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scrap Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Scrap Cutter is responsible for cutting scrap metal into smaller pieces using a variety of tools. This role requires physical strength, attention to detail, and the ability to work safely. The following are some of the key job responsibilities:

1. Cutting Scrap Metal

The primary responsibility of a Scrap Cutter is to cut scrap metal into smaller pieces. This may involve using a variety of tools, such as shears, saws, or torches.

- Operate a variety of cutting equipment to cut scrap metal into smaller pieces.

- Use shears, saws, or torches to cut metal to specified dimensions

- Ensure that all cuts are made in a safe and efficient manner

2. Sorting and Grading Scrap Metal

In addition to cutting scrap metal, Scrap Cutters are also responsible for sorting and grading it. This involves identifying different types of metal and separating them into different grades. The most common types of scrap metal include ferrous and non-ferrous metals.

- Sort and grade ferrous and non-ferrous scrap metals

- Identify and separate different grades of scrap metal

- Maintain a clean and organized work area

3. Bale and Package Scrap Metal

Once scrap metal has been sorted and graded, it is often baled or packaged into bundles. This makes it easier to transport and store. Scrap Cutters are responsible for operating balers and packaging machines.

- Operate balers and packaging machines to prepare scrap metal for shipment

- Ensure that all materials are securely packaged and loaded onto trucks

- Maintain a safe and efficient work environment

4. Maintaining Equipment

Scrap Cutters are also responsible for maintaining their equipment. This includes cleaning, lubricating, and inspecting tools and machinery. They also need to be able to troubleshoot and repair minor problems.

- Clean, lubricate, and inspect tools and machinery

- Troubleshoot and repair minor problems

- Follow all safety regulations and procedures

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success.

1. Research the Company and the Position

One of the best ways to prepare for an interview is to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to tailor your answers to the specific requirements of the job.

- Visit the company’s website and social media pages

- Read articles about the company and the industry

- Talk to people who work at the company, if possible

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can do so confidently and concisely.

- Write down your answers to common interview questions

- Practice answering these questions out loud

- Get feedback from a friend or family member

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This will show the interviewer that you are punctual and respectful of their time.

- Choose appropriate business attire

- Make sure your clothes are clean and pressed

- Arrive on time or early for your interview

4. Be Yourself and Be Enthusiastic

It is important to be yourself during an interview. The interviewer wants to get to know the real you, not a fake version of yourself. Be confident and enthusiastic about the position and the company. This will show the interviewer that you are genuinely interested in the job.

- Be honest and authentic in your answers

- Show your enthusiasm for the position and the company

- Ask questions and participate in the conversation

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Scrap Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!