Are you gearing up for a career in Scrap Iron Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Scrap Iron Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

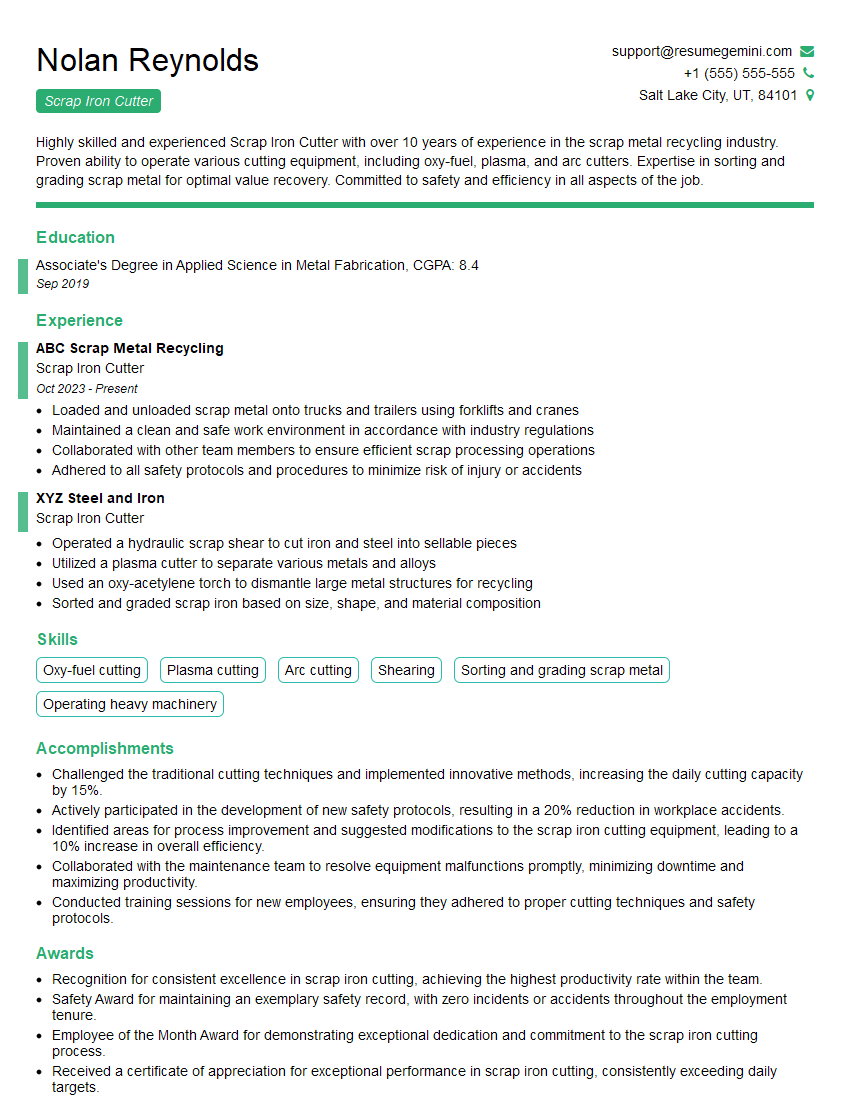

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scrap Iron Cutter

1. What are the different types of scrap iron cutters and how do they work?

- Shears: Shears are used to cut straight lines in scrap iron. They are typically powered by hydraulics or electricity and can be either manual or automatic.

- Car balers: Car balers are used to compress scrap iron into bales. They are typically powered by hydraulics and can be either manual or automatic.

- Shredders: Shredders are used to break scrap iron into small pieces. They can be either single-stage or two-stage and are typically powered by electricity.

2. What are the safety precautions that need to be taken when operating a scrap iron cutter?

Personal Protective Equipment

- Wear proper eye protection, such as safety glasses or goggles, to protect your eyes from flying debris.

- Wear earplugs or ear muffs to protect your hearing from loud noise.

- Wear gloves to protect your hands from cuts and abrasions.

Machine Safety

- Make sure the machine is properly grounded to prevent electrical shock.

- Never operate the machine if it is damaged.

- Keep the work area clean and free of debris.

3. What are the different types of scrap iron that can be cut?

- Ferrous scrap: Ferrous scrap is iron or steel that contains iron oxide. It is the most common type of scrap iron and can be recycled into new steel.

- Non-ferrous scrap: Non-ferrous scrap is iron or steel that does not contain iron oxide. It includes metals such as aluminum, copper, and brass.

4. What are the different applications for scrap iron?

- Ferrous scrap: Ferrous scrap can be recycled into new steel, which is used in a variety of applications, including construction, automotive manufacturing, and shipbuilding.

- Non-ferrous scrap: Non-ferrous scrap can be recycled into new non-ferrous metals, which are used in a variety of applications, including electrical wiring, plumbing, and jewelry.

5. What are the environmental benefits of recycling scrap iron?

- Reduces air pollution: Recycling scrap iron reduces the amount of air pollution caused by mining and smelting new iron ore.

- Reduces water pollution: Recycling scrap iron reduces the amount of water pollution caused by mining and smelting new iron ore.

- Reduces greenhouse gas emissions: Recycling scrap iron reduces the amount of greenhouse gas emissions caused by mining and smelting new iron ore.

6. What are the economic benefits of recycling scrap iron?

- Creates jobs: The scrap iron recycling industry creates jobs in a variety of fields, including collection, processing, and manufacturing.

- Saves money: Recycling scrap iron saves money by reducing the need to mine and smelt new iron ore.

- Generates revenue: Scrap iron can be sold to recyclers for a profit.

7. What are some of the challenges associated with recycling scrap iron?

- Collection: Collecting scrap iron can be difficult, especially in rural areas.

- Processing: Processing scrap iron can be energy-intensive and can generate pollutants.

- Market fluctuations: The price of scrap iron can fluctuate, which can make it difficult for recyclers to make a profit.

8. What are some of the emerging technologies that are being used to recycle scrap iron?

- Artificial intelligence (AI): AI is being used to develop new methods for sorting and processing scrap iron.

- Blockchain: Blockchain is being used to create transparent and efficient supply chains for scrap iron.

- Internet of Things (IoT): IoT is being used to track and monitor scrap iron recycling operations.

9. What are some of the trends that are shaping the future of scrap iron recycling?

- Increasing demand for recycled materials: The demand for recycled materials is increasing as companies become more aware of the environmental and economic benefits of recycling.

- Technological advancements: Technological advancements are making it easier and more efficient to recycle scrap iron.

- Increased government support: Governments are increasingly supporting scrap iron recycling through policies and incentives.

10. What are some of the challenges that the scrap iron recycling industry is facing?

- Fluctuating prices: The price of scrap iron can fluctuate, which can make it difficult for recyclers to make a profit.

- Competition from overseas markets: Scrap iron recyclers in the United States face competition from overseas markets, where the cost of labor is lower.

- Environmental regulations: Environmental regulations can make it difficult and expensive to recycle scrap iron.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scrap Iron Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scrap Iron Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scrap Iron Cutters are responsible for cutting and preparing scrap iron for recycling or reuse. They use specialized equipment to cut iron into smaller pieces or into specific shapes. Some of their key job responsibilities include:

1. Cutting Iron

Using plasma cutters or oxy-acetylene torches to cut iron into smaller pieces or into specific shapes.

2. Sorting and Grading Scrap Iron

Inspecting and sorting scrap iron to determine its grade and value. They may also use magnets to separate ferrous (magnetic) and non-ferrous (non-magnetic) metals.

3. Loading and Unloading Scrap Iron

Using forklifts or cranes to load and unload scrap iron from trucks, trailers, or other storage areas.

4. Maintaining Equipment

Performing basic maintenance and repairs on cutting equipment, such as plasma cutters and oxy-acetylene torches.

5. Complying with Safety Regulations

Adhering to all safety regulations and using proper safety equipment, such as gloves, eye protection, and respirators.

Interview Tips

To help you ace your interview for a Scrap Iron Cutter position, here are some tips and preparation hacks:

1. Research the Company

Before the interview, take some time to research the company you’re applying to. This will help you understand their business, their values, and their specific needs for the Scrap Iron Cutter role.

2. Highlight Relevant Skills

In your resume and during the interview, emphasize the skills and experience that are most relevant to the job. For example, highlight your experience with cutting iron using plasma cutters or oxy-acetylene torches, your ability to sort and grade scrap iron, and your knowledge of safety regulations.

3. Be Prepared to Discuss Safety

Safety is a top priority in the scrap metal industry. Be prepared to discuss your understanding of safety regulations and your experience with using safety equipment, such as gloves, eye protection, and respirators.

4. Prepare Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. Prepare a few questions about the company, the job, or the industry. This is also an opportunity to clarify any information you may have missed or to get more details about the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Scrap Iron Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Scrap Iron Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.