Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Scrap Piler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

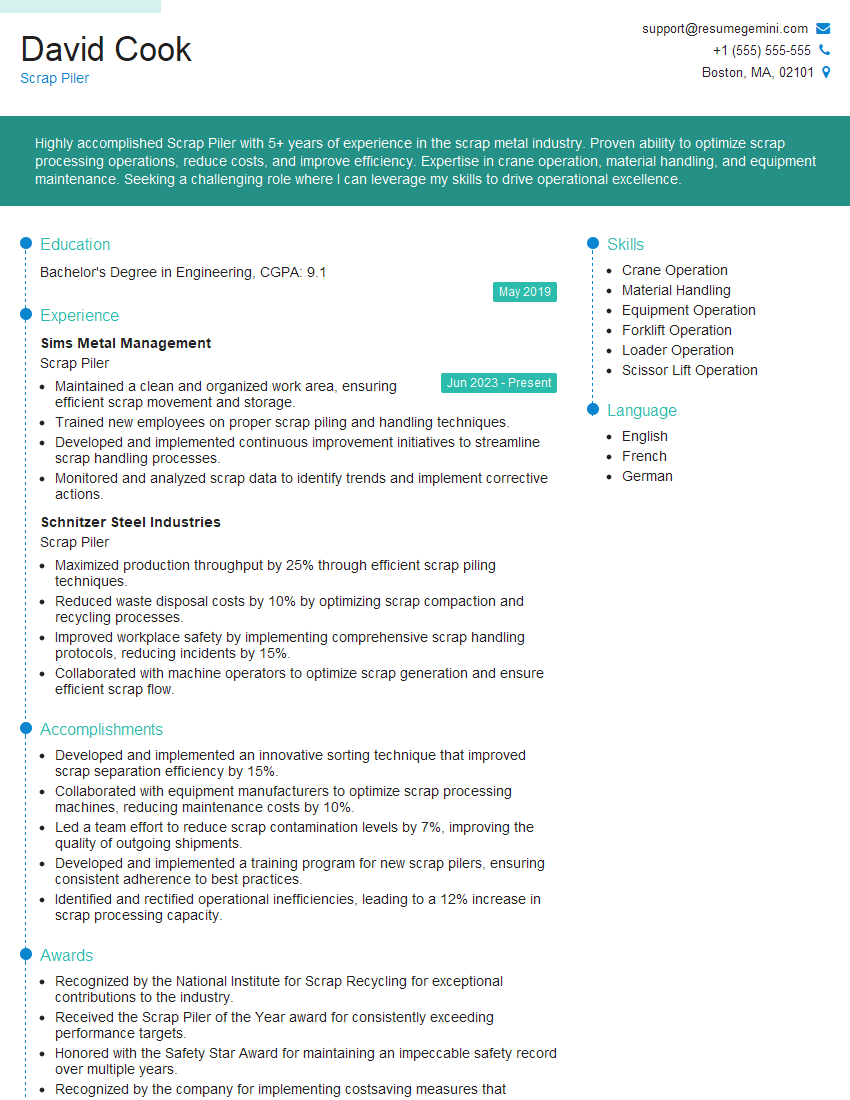

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scrap Piler

1. What are the different methods of scrap piling?

There are several methods of scrap piling, including:

- Manual Piling: Scrap is piled by hand.

- Mechanical Piling: Scrap is piled using machinery such as cranes, excavators, and magnets.

- Automated Piling: Scrap is piled using automated systems that use sensors and robotics.

2. What are the safety measures that need to be taken when piling scrap?

General Safety Measures

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats.

- Be aware of your surroundings and potential hazards.

- Follow safe work practices.

Specific Safety Measures

- Manual Piling: Use proper lifting techniques and avoid overexertion.

- Mechanical Piling: Operate machinery safely and follow manufacturer’s instructions.

- Automated Piling: Ensure systems are properly maintained and programmed.

3. What are the factors that affect the stability of a scrap pile?

The stability of a scrap pile is affected by several factors, including:

- Shape and Height: Taller and thinner piles are less stable than shorter and wider piles.

- Material Type: Different scrap materials have different densities and friction coefficients, affecting stability.

- Moisture Content: Wet scrap is more slippery and less stable than dry scrap.

4. What are the different types of scrap and how do they affect the piling process?

Different types of scrap include ferrous (steel) and non-ferrous (aluminum, copper) metals, as well as plastics, paper, and wood. Each type has unique properties that affect piling, such as:

- Ferrous Metals: Heavy and dense, requiring stronger structures for piling.

- Non-Ferrous Metals: Lighter and less dense, allowing for taller piles.

- Plastics: Bulky and lightweight, requiring special techniques for compaction.

5. What are the latest technologies and advancements in scrap piling?

Recent advancements in scrap piling include:

- Automated Pile Management Systems: Use sensors and software to monitor and optimize pile stability.

- Remote Control Scrap Piling Equipment: Allows operators to control machinery from a safe distance.

- 3D Scanning and Modeling: Creates detailed models of scrap piles for planning and analysis.

6. How do you ensure the quality and accuracy of the scrap piles?

To ensure quality and accuracy, I follow these steps:

- Proper Sorting and Segregation: Separate different types of scrap materials to maintain purity and value.

- Regular Inspections: Conduct routine inspections of scrap piles to check for stability, contamination, and potential hazards.

- Weight Measurement and Tracking: Use calibrated scales to accurately measure scrap weight and track inventory levels.

7. What are the environmental regulations and safety standards that apply to scrap piling?

The following regulations and standards apply to scrap piling:

- OSHA Regulations: Establish safety standards for workers handling and storing scrap materials.

- EPA Regulations: Regulate the storage and disposal of hazardous materials that may be present in scrap.

- Local and State Regulations: Vary depending on location and may include specific requirements for piling and storage.

8. How do you optimize the use of space when piling scrap?

To optimize space utilization, I employ the following techniques:

- Vertical Piling: Maximize height by creating tall and stable piles.

- Compact Storage: Use techniques such as shredding and baling to reduce the volume of scrap.

- Efficient Yard Layout: Plan the layout of the scrap yard to allow for easy access and movement of equipment.

9. How do you handle and dispose of contaminated scrap?

Contaminated scrap is handled and disposed of according to specific regulations:

- Identifying Contamination: Inspect and test scrap for potential contaminants.

- Segregating Contaminated Scrap: Isolate contaminated scrap from non-contaminated materials.

- Proper Disposal: Follow established procedures for disposing of hazardous or contaminated scrap through licensed waste management companies.

10. How do you stay updated on best practices and advancements in scrap piling?

To stay updated, I engage in the following activities:

- Industry Conferences and Trade Shows: Attend events to learn about new technologies and practices.

- Reading Trade Publications and Journals: Stay informed about industry news and best practices.

- Networking with Peers: Share knowledge and experiences with other scrap professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scrap Piler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scrap Piler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A scrap piler is responsible for safely and efficiently piling scrap metal in a scrapyard or recycling facility. Key job responsibilities include:

1. Operating Equipment

Scrap pilers operate various types of equipment to move and pile scrap metal, such as cranes, forklifts, and bulldozers. They must be able to operate this equipment safely and efficiently to ensure the smooth flow of operations.

2. Managing Scrap Material

Scrap pilers are responsible for managing the flow of scrap metal through the facility. This includes sorting and segregating scrap metal according to type, grade, and size. They must also keep track of the inventory of scrap metal and maintain accurate records.

3. Maintaining Safety Standards

Scrap pilers work in a hazardous environment, so they must follow all safety rules and regulations. They must wear appropriate personal protective equipment (PPE) and be aware of potential hazards such as falling objects, moving equipment, and sharp edges.

4. Customer Service

Scrap pilers may interact with customers who are dropping off or picking up scrap metal. They must be able to provide good customer service and answer any questions that customers may have.

Interview Tips

To ace an interview for a scrap piler position, candidates should be prepared to discuss their experience and skills related to the key job responsibilities. Here are some interview tips to help candidates prepare:

1. Research the Company and Industry

Candidates should research the company and the scrap metal industry before the interview. This will help them understand the company’s culture and values, as well as the current trends and challenges in the industry.

2. Highlight Relevant Experience and Skills

Candidates should highlight their relevant experience and skills in their resume and cover letter. They should also be prepared to discuss their experience in operating equipment, managing scrap material, maintaining safety standards, and providing customer service.

3. Prepare for Common Interview Questions

Candidates should prepare for common interview questions such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. They should also be prepared to provide examples of their experience and skills that relate to the key job responsibilities.

4. Dress Professionally and Arrive on Time

Candidates should dress professionally and arrive on time for the interview. This will demonstrate their respect for the interviewer and the company.

5. Ask Questions

Candidates should ask questions at the end of the interview to show their interest in the position and the company. This is also an opportunity to learn more about the job and the company culture.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Scrap Piler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!