Feeling lost in a sea of interview questions? Landed that dream interview for Scratch Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Scratch Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

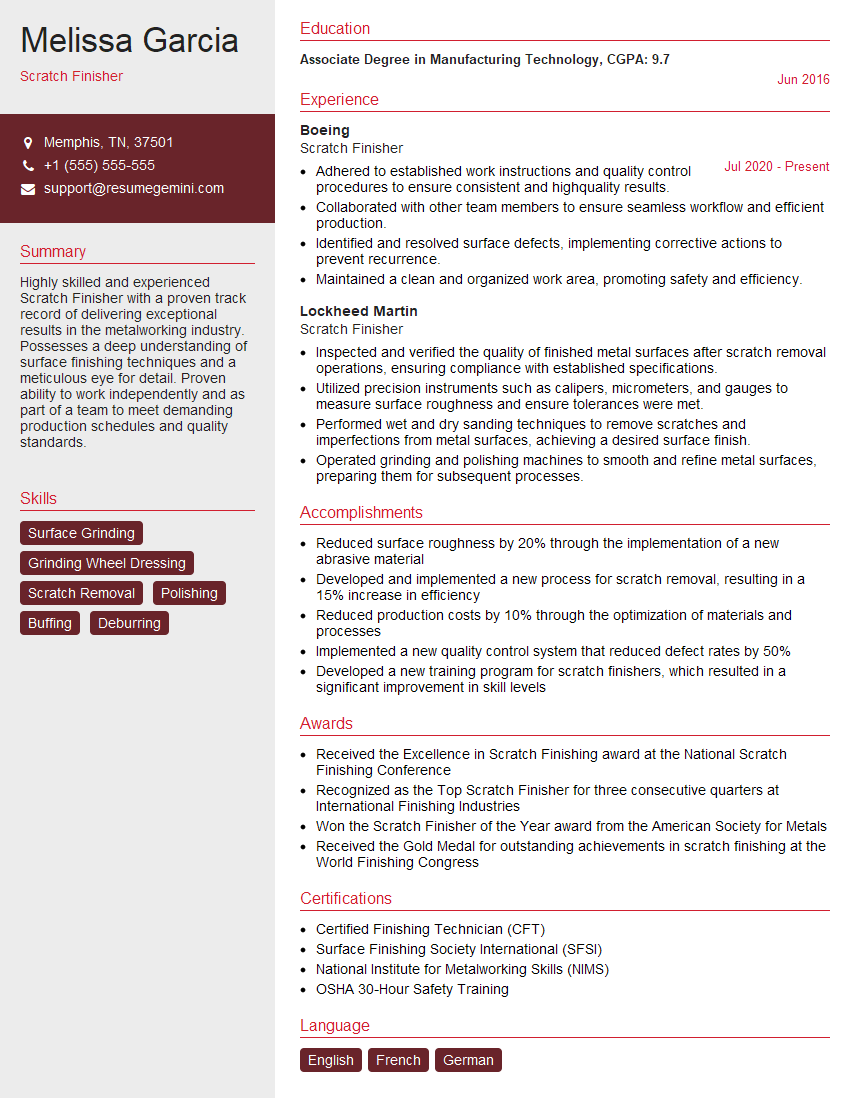

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scratch Finisher

1. What are the different types of abrasives used in scratch finishing?

- Diamond

- Cubic boron nitride (CBN)

- Silicon carbide

- Aluminum oxide

- Zirconia alumina

2. What are the different methods of scratch finishing?

Mechanical methods

- Grinding

- Lapping

- Honing

- Superfinishing

Chemical methods

- Etching

- Polishing

- Buffing

3. What are the factors that affect the surface finish of a scratch-finished part?

- Type of abrasive

- Grit size of the abrasive

- Speed of the abrasive

- Pressure of the abrasive

- Type of workpiece material

- Hardness of the workpiece material

- Cooling method

4. What are the applications of scratch finishing?

- Automotive parts

- Aerospace parts

- Medical devices

- Optical components

- Precision instruments

5. What are the advantages of scratch finishing?

- Improved surface finish

- Reduced friction

- Increased wear resistance

- Enhanced corrosion resistance

- Improved appearance

6. What are the disadvantages of scratch finishing?

- Can be time-consuming

- Can be expensive

- Requires specialized equipment

- Can be difficult to achieve consistent results

7. What are the safety precautions that should be taken when performing scratch finishing?

- Wear appropriate safety gear, including gloves, eye protection, and a respirator

- Use sharp tools and abrasives

- Keep the work area clean and free of debris

- Follow all manufacturer’s instructions

8. What are the latest trends in scratch finishing?

- Use of nanomaterials

- Development of new abrasive materials

- Increased use of automation

- Focus on sustainability

9. What are the challenges facing the scratch finishing industry?

- Rising cost of materials

- Increased competition from overseas

- Need for skilled workers

- Environmental regulations

10. What are the opportunities for growth in the scratch finishing industry?

- Growing demand for precision parts

- Development of new applications

- Increased use of automation

- Focus on sustainability

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scratch Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scratch Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scratch Finishers are responsible for smoothing and polishing metal surfaces to achieve a smooth, consistent finish. Their primary duties include:

1. Surface Preparation

Preparing metal surfaces by cleaning, abrading, and applying protective coatings.

- Removing rust, dirt, and other contaminants from surfaces using solvents, brushes, and abrasives.

- Applying primers, sealers, or other coatings to protect surfaces from corrosion and improve adhesion.

2. Scratching and Smoothing

Using brushes, sanding pads, and abrasives to smooth and remove imperfections from surfaces.

- Sanding or grinding surfaces with abrasives of varying grits to remove scratches and unevenness.

- Polishing surfaces using buffers and polishes to achieve a smooth, glossy finish.

3. Inspection and Quality Control

Inspecting finished surfaces to ensure they meet required standards and specifications.

- Using measuring tools and gauges to verify dimensions, flatness, and finish quality.

- Identifying and correcting any defects or inconsistencies in the finish.

4. Safety and Maintenance

Maintaining a safe and organized work environment.

- Wearing appropriate personal protective equipment (PPE) and following safety protocols.

- Cleaning and maintaining equipment, tools, and the work area to ensure optimal performance.

Interview Tips

To ace the interview for a Scratch Finisher position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This demonstrates your interest and knowledge of the field.

- Visit the company website to learn about their history, mission, and specialties.

- Read industry publications and articles to stay updated on advancements in finishing techniques.

2. Practice Common Interview Questions

Prepare for typical interview questions related to your skills, experience, and motivation. Practice answering them clearly and concisely.

- Describe your experience with surface preparation and finishing techniques.

- How do you ensure the quality and consistency of your work?

- Why are you interested in this position and our company?

3. Highlight Relevant Skills and Experience

Emphasize your technical skills in scratch finishing, such as sanding, polishing, and inspection. Quantify your accomplishments to demonstrate your impact.

- Mention specific projects where you improved surface quality or reduced finishing time.

- Provide numerical examples of your accuracy and attention to detail.

4. Show Enthusiasm and Motivation

Convey your passion for finishing and your desire to contribute to the company’s success. Highlight your willingness to learn and grow.

- Share your knowledge of new finishing technologies or industry best practices.

- Express your eagerness to collaborate with team members and contribute to the team’s goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Scratch Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!