Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Screen Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

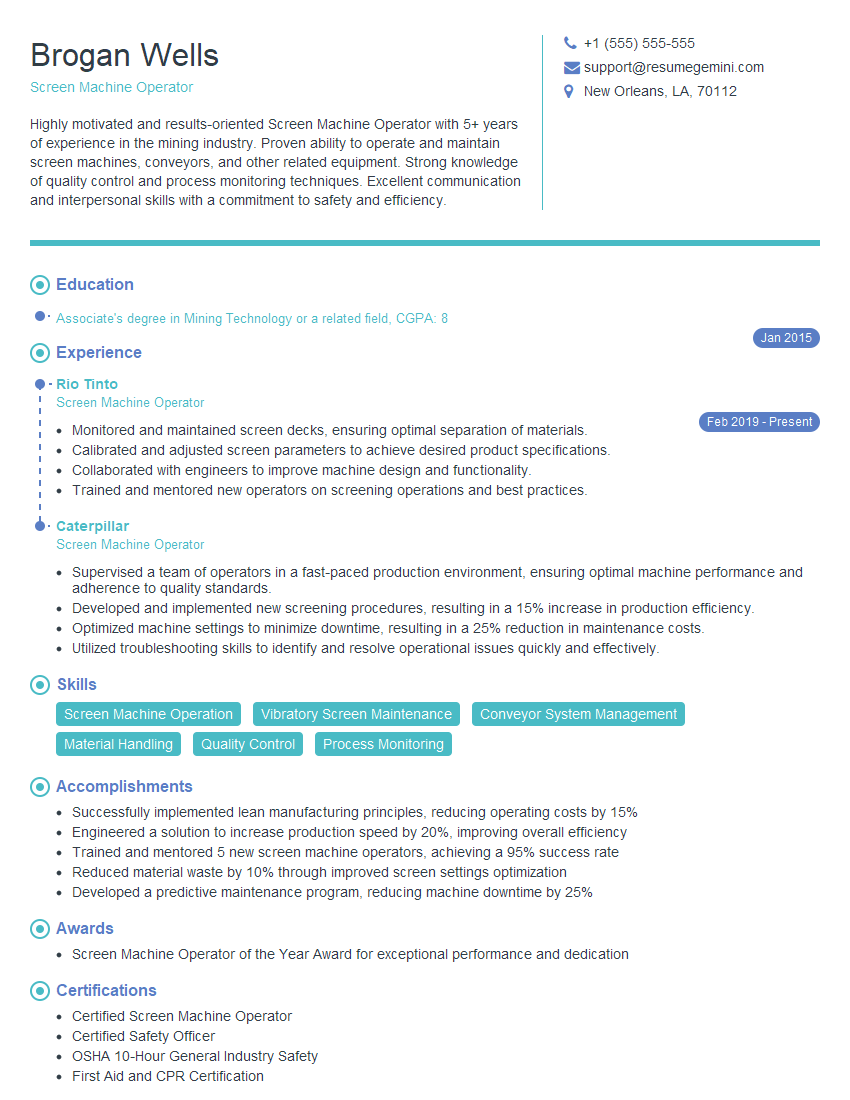

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Machine Operator

1. What are the responsibilities of a Screen Machine Operator?

As a Screen Machine Operator, I am responsible for:

- Operating and monitoring screen machines to separate materials based on size

- Adjusting screen settings to achieve desired separation and efficiency

- Inspecting screens for wear and tear, and replacing or repairing as needed

- Cleaning and maintaining screen machines to ensure optimal performance

- Monitoring production rates and ensuring that machines are operating at peak capacity

2. What are the different types of screen machines and how do they operate?

There are various types of screen machines, each designed for specific applications. Some common types include:

Vibratory Screen Machine

- Uses vibrations to move materials across a screen surface

- Effective for separating materials with different particle sizes and shapes

Rotary Screen Machine

- Consists of a rotating cylindrical screen

- Separates materials based on size as they pass through the rotating screen

Magnetic Screen Machine

- Utilizes magnets to separate ferrous materials from non-ferrous materials

- Often used in recycling applications

3. What are the key factors to consider when selecting a screen machine?

When selecting a screen machine, it is important to consider the following factors:

- Material to be screened: Type, particle size, and shape

- Desired separation efficiency and capacity

- Available space and power requirements

- Operating environment: Temperature, humidity, and potential hazards

- Budget and availability of skilled operators

4. How do you ensure the accuracy and efficiency of a screen machine?

To ensure accuracy and efficiency, I:

- Calibrate the screen machine regularly using standard samples

- Monitor the feed rate and make adjustments as needed to maintain optimal performance

- Inspect the screen surface for wear and damage, and replace or repair promptly

- Clean the screen machine thoroughly to prevent clogging and ensure smooth operation

- Adhere to established operating procedures and protocols

5. What troubleshooting techniques do you employ when a screen machine malfunctions?

In case of malfunctions, I follow a systematic troubleshooting process:

- Identify the symptoms of the problem, such as reduced capacity or inaccurate separation

- Check the power supply, screens, and other components for any visible issues

- Review operating parameters and compare them to established standards

- Consult maintenance manuals and technical documentation for guidance

- Request assistance from maintenance personnel if necessary

6. How do you prioritize tasks and manage your time effectively?

I prioritize tasks based on their urgency and impact on production. I:

- Use a task management system to track progress and deadlines

- Delegate tasks to other team members when possible

- Break down large tasks into smaller, manageable steps

- Take regular breaks to maintain focus and productivity

- Communicate regularly with supervisors to ensure alignment

7. How do you maintain a safe and clean work environment in the screen machine area?

I am committed to maintaining a safe and clean work environment:

- Wear appropriate personal protective equipment, including safety goggles, earplugs, and gloves

- Operate machines in accordance with established safety protocols

- Keep the work area free from debris and spills

- Follow proper lockout/tagout procedures when servicing or repairing machines

- Report any potential hazards or unsafe conditions to supervisors immediately

8. How do you stay updated on the latest advancements in screen machine technology?

To stay updated on the latest advancements, I:

- Attend industry conferences and workshops

- Read technical publications and articles

- Connect with professionals in the field

- Seek out training opportunities provided by manufacturers

- Participate in online forums and discussions

9. How do you handle pressure and work effectively in a fast-paced production environment?

I thrive in fast-paced environments and manage pressure effectively through:

- Maintaining a calm and focused demeanor

- Prioritizing tasks and delegating responsibilities

- Communicating clearly and concisely with colleagues

- Seeking support from supervisors and peers when needed

- Taking regular breaks to clear my mind and recharge

10. Why are you interested in this Screen Machine Operator position, and how do you believe your skills and experience align with the requirements?

I am eager to join your company as a Screen Machine Operator because:

- My previous experience in operating and maintaining screen machines aligns perfectly with the requirements of this role

- I am confident in my ability to contribute to the team’s productivity and efficiency

- I am a highly motivated and results-oriented individual with a strong work ethic

- I am eager to learn new techniques and technologies to enhance my skills

- I am committed to maintaining a safe and productive work environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Screen Machine Operators are responsible for operating and maintaining screen machines, which are used to separate materials based on their size. Key job responsibilities include:

1. Operating Screen Machines

Monitor and control screen machines to separate materials based on size.

- Adjust machine settings to achieve optimal separation results.

- Monitor material flow to prevent jams and other problems.

2. Maintaining Screen Machines

Perform routine maintenance and repairs on screen machines.

- Clean and lubricate moving parts.

- Inspect screens for damage and replace as needed.

3. Troubleshooting Problems

Identify and resolve problems with screen machines.

- Diagnose electrical and mechanical problems.

- Repair or replace faulty components.

4. Maintaining a Safe Work Environment

Follow safety procedures and regulations.

- Wear appropriate personal protective equipment.

- Keep work area clean and organized.

Interview Tips

To ace the interview for a Screen Machine Operator position, it’s important to prepare thoroughly and demonstrate your skills and experience. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you’re applying for. This will help you understand the company’s culture, goals, and the requirements of the job.

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in Screen Machine Operator interviews. Practice answering these questions clearly and concisely, providing specific examples of your skills and experience.

3. Highlight Your Skills and Experience

In your resume and cover letter, be sure to highlight your skills and experience that are relevant to the job. For example, mention any experience you have operating and maintaining screen machines, troubleshooting problems, or maintaining a safe work environment.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for the interview and arrive on time. This shows the interviewer that you respect their time and that you’re serious about the position.

5. Be Enthusiastic and Confident

Finally, remember to be enthusiastic and confident in your interview. Screen Machine Operators are often responsible for ensuring that the production process runs smoothly, so employers are looking for candidates who are positive, motivated, and have a strong work ethic.

Next Step:

Now that you’re armed with the knowledge of Screen Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Screen Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini