Feeling lost in a sea of interview questions? Landed that dream interview for Screen Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Screen Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

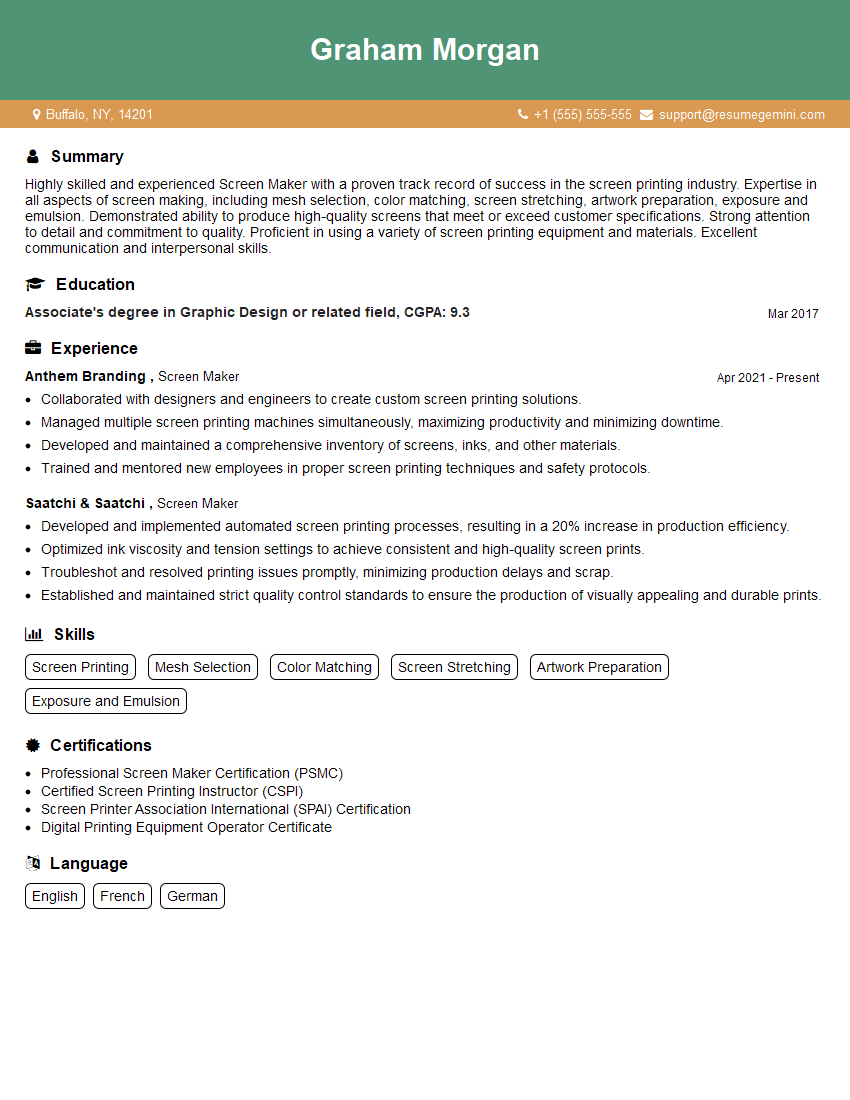

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Maker

1. What are the different types of screen materials and what are their respective advantages and disadvantages?

There are several types of screen materials available, each with its own advantages and disadvantages.

- Polyester: Polyester is a durable and affordable material that is resistant to fading and tearing. It is also lightweight and easy to clean.

- Fiberglass: Fiberglass is another durable and affordable material that is resistant to fire and insects. It is also lightweight and easy to install.

- Aluminum: Aluminum is a strong and durable material that is resistant to corrosion. It is also lightweight and easy to clean.

- Copper: Copper is a durable and corrosion-resistant material that is also antimicrobial. It is more expensive than other materials but can last for many years.

2. What are the different types of screen weaves?

There are several different types of screen weaves, each with its own advantages and disadvantages.

- Plain weave: Plain weave is the most common type of screen weave. It is created by weaving the warp and weft threads over and under each other in a simple, alternating pattern.

- Twill weave: Twill weave is a more complex weave that creates a diagonal pattern. It is stronger than plain weave and is often used for heavier fabrics.

- Satin weave: Satin weave is a smooth and lustrous weave that is created by floating the warp or weft threads over multiple weft or warp threads, respectively.

3. What are the different types of screen frames?

There are several different types of screen frames, each with its own advantages and disadvantages.

- Wood frames: Wood frames are the most common type of screen frame. They are made from durable hardwoods like oak, mahogany, or cedar.

- Metal frames: Metal frames are made from materials like aluminum or steel. They are strong and durable but can be more expensive than wood frames.

- Vinyl frames: Vinyl frames are made from a durable plastic material. They are lightweight and easy to clean but can be more prone to fading and warping than other types of frames.

4. What are the different methods of screen printing?

There are several different methods of screen printing, each with its own advantages and disadvantages.

- Hand screen printing: Hand screen printing is a traditional method of screen printing that uses a hand-held squeegee to force ink through a screen onto a substrate.

- Automatic screen printing: Automatic screen printing is a more modern method of screen printing that uses a machine to automate the process.

- Digital screen printing: Digital screen printing is a newer method of screen printing that uses a computer to create a digital image of the design that is then transferred to a screen.

5. What are the different types of screen printing inks?

There are several different types of screen printing inks, each with its own advantages and disadvantages.

- Plastisol inks: Plastisol inks are the most common type of screen printing ink. They are made from a PVC resin and are durable and resistant to fading.

- Water-based inks: Water-based inks are made from a water-based resin and are more environmentally friendly than plastisol inks. They can be less durable than plastisol inks but are easier to clean up.

- Discharge inks: Discharge inks are a type of water-based ink that is used to create a vintage or distressed look. They work by removing the dye from the fabric, leaving behind the color of the ink.

6. What are the different factors that affect the quality of a screen print?

There are several different factors that can affect the quality of a screen print, including:

- The quality of the screen: The quality of the screen can affect the sharpness and detail of the print.

- The quality of the ink: The quality of the ink can affect the durability and vibrancy of the print.

- The quality of the substrate: The quality of the substrate can affect the adhesion and durability of the print.

- The skill of the printer: The skill of the printer can affect the overall quality of the print.

7. What are the different types of screen printing equipment?

There are several different types of screen printing equipment, including:

- Screen printing press: The screen printing press is the main piece of equipment used in screen printing. It holds the screen in place and applies pressure to force the ink through the screen onto the substrate.

- Squeegee: The squeegee is a hand-held tool used to apply pressure to the screen and force the ink through the screen.

- Flash dryer: The flash dryer is used to dry the ink on the substrate after it has been printed.

- Exposure unit: The exposure unit is used to expose the screen to light, which hardens the emulsion and creates the image.

8. What are the different safety precautions that should be taken when screen printing?

There are several different safety precautions that should be taken when screen printing, including:

- Wear appropriate safety gear: This includes gloves, a mask, and safety glasses.

- Use proper ventilation: The fumes from screen printing inks can be harmful if inhaled.

- Store chemicals properly: Screen printing inks and other chemicals should be stored in a safe and well-ventilated area.

- Dispose of waste properly: Screen printing waste should be disposed of in accordance with local regulations.

9. What are the different troubleshooting tips for screen printing?

There are several different troubleshooting tips for screen printing, including:

- If the ink is not adhering to the substrate: This could be caused by a number of factors, including the quality of the ink, the quality of the substrate, or the temperature of the substrate.

- If the print is blurry: This could be caused by a number of factors, including the quality of the screen, the quality of the ink, or the skill of the printer.

- If the print is faded: This could be caused by a number of factors, including the quality of the ink, the exposure time, or the temperature of the flash dryer.

10. What are the different trends in screen printing?

There are several different trends in screen printing, including:

- Digital screen printing: Digital screen printing is a newer method of screen printing that uses a computer to create a digital image of the design that is then transferred to a screen.

- Water-based inks: Water-based inks are more environmentally friendly than plastisol inks and can be used to create a wider range of effects.

- Discharge inks: Discharge inks are a type of water-based ink that is used to create a vintage or distressed look.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Screen Makers, also known as Silk Screen Printers, are responsible for creating custom designs and images on various surfaces using silk screening techniques. Their primary job responsibilities include:1. Stencil Creation

2. Screen Preparation

3. Printing

4. Quality Control

5. Equipment Maintenance

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some interview tips and hacks to help job seekers ace their Screen Maker interview:1. Research the Company and the Role

2. Prepare Examples of Your Work

3. Practice Your Responses

4. Dress Professionally

5. Network with Industry Professionals

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Screen Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.