Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Screen Printer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Screen Printer so you can tailor your answers to impress potential employers.

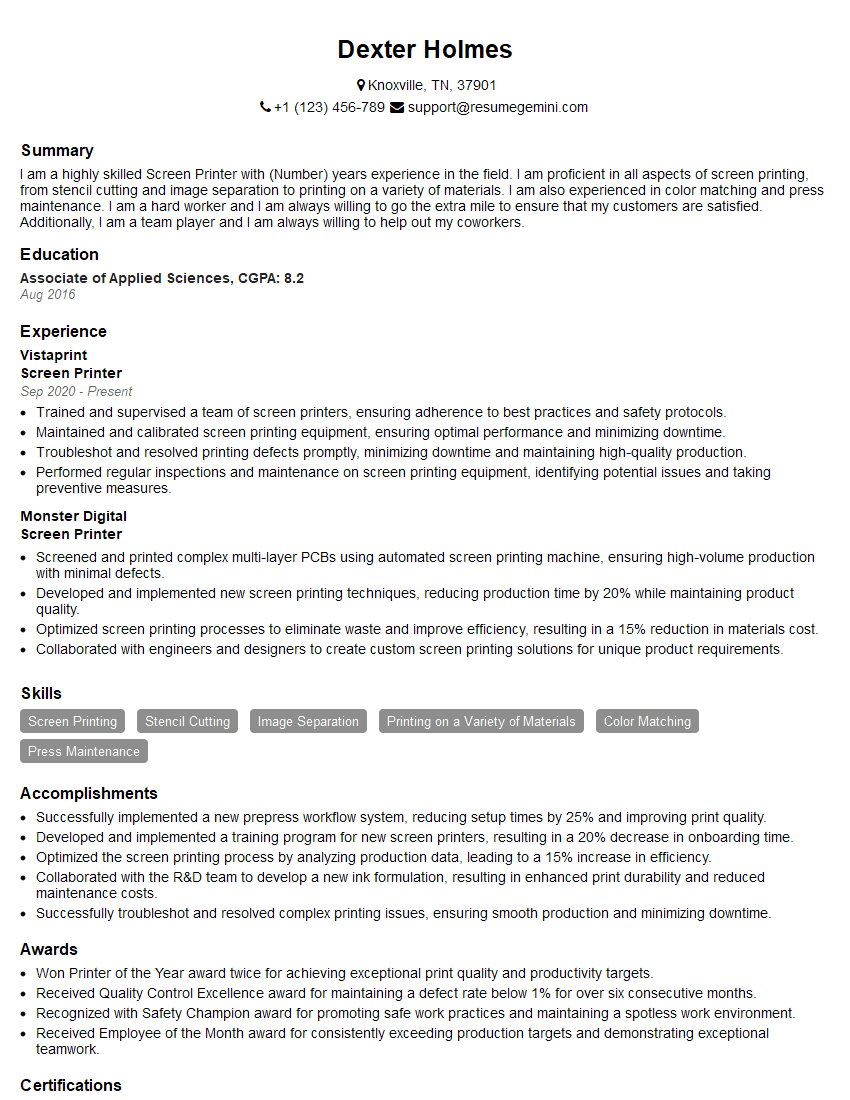

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Printer

1. What are the different types of screen printing techniques?

There are several types of screen printing techniques, including:

- Flatbed screen printing: This technique uses a flatbed printer to press the ink through a screen onto the substrate.

- Rotary screen printing: This technique uses a rotary press to transfer the ink from a screen onto the substrate.

- Textile screen printing: This technique is used to print designs onto fabrics and other textiles.

- Digital screen printing: This technique uses a digital printer to create the image on the screen, which is then transferred to the substrate.

2. What are the factors that affect the quality of a screen printed product?

Substrate quality

- The quality of the substrate, such as its smoothness, porosity, and thickness, can affect the adhesion and durability of the ink.

Ink quality

- The type of ink used, such as its viscosity, color, and opacity, can affect the printability and appearance of the finished product.

3. What are the common problems that can occur during screen printing and how do you troubleshoot them?

Some common problems that can occur during screen printing include:

- Registration errors: These occur when the printed image is not aligned correctly with the substrate.

- Bleeding: This occurs when the ink spreads beyond the intended area, resulting in a blurred or distorted image.

- Ghosting: This occurs when a faint image of the previously printed design appears on the substrate.

4. What are the different types of screens used in screen printing and what are their advantages and disadvantages?

The different types of screens used in screen printing include:

- Mesh screens: These screens are made of a fine mesh fabric, which allows the ink to pass through while blocking the solids.

- Stencil screens: These screens are made of a solid material, such as metal or plastic, which is cut to create the desired design.

Advantages and Disadvantages

- Mesh screens are more durable and can be used for longer runs, but they can be more expensive than stencil screens.

- Stencil screens are less durable and can only be used for shorter runs, but they are less expensive than mesh screens.

5. What are the safety precautions that should be taken when working with screen printing equipment?

Some of the safety precautions that should be taken when working with screen printing equipment include:

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and a respirator.

- Ensuring that the equipment is properly grounded and that all electrical connections are secure.

- Keeping the work area clean and free of flammable materials.

- Following the manufacturer’s instructions for the safe use of the equipment.

6. What are the different types of inks used in screen printing and what are their advantages and disadvantages?

The different types of inks used in screen printing include:

- Water-based inks: These inks are made with water and are environmentally friendly.

- Solvent-based inks: These inks are made with solvents and are more durable than water-based inks.

- UV-curable inks: These inks are cured by exposure to ultraviolet light and are very durable.

Advantages and Disadvantages

- Water-based inks are less expensive than other types of inks, but they are not as durable.

- Solvent-based inks are more durable than water-based inks, but they can be more expensive and can produce harmful fumes.

- UV-curable inks are very durable and can produce high-quality prints, but they can be more expensive than other types of inks.

7. What are the different types of substrates that can be used in screen printing?

The different types of substrates that can be used in screen printing include:

- Paper

- Cardboard

- Plastic

- Metal

- Textiles

- Wood

8. What are the different applications of screen printing?

Screen printing has a wide range of applications, including:

- Printing posters, banners, and signs

- Printing T-shirts, hoodies, and other clothing

- Printing decals and labels

- Printing electronic circuits

9. What is the difference between screen printing and digital printing?

- Screen printing is a printing technique that uses a mesh screen to transfer ink onto a substrate.

- Digital printing is a printing technique that uses a digital file to create an image on a substrate.

Advantages and Disadvantages

- Screen printing is more cost-effective for large print runs.

- Digital printing is more cost-effective for small print runs.

- Screen printing can produce higher-quality prints.

- Digital printing is faster than screen printing.

10. What are the latest trends in screen printing?

Some of the latest trends in screen printing include:

- The use of digital technology to create screens and prints

- The use of new inks and substrates

- The development of new printing techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Screen Printers are responsible for operating and maintaining screen printing machines to produce high-quality printed materials. They work closely with other members of the production team to ensure that all orders are completed on time and to the required specifications.

1. Preparing and Setting Up Equipment

Screen Printers begin by preparing and setting up the screen printing equipment. This includes selecting the appropriate screens, inks, and substrates, and making sure that the machine is properly calibrated.

- Select and prepare screens, inks, and substrates

- Calibrate and adjust screen printing machine

- Ensure that all equipment is in good working order

2. Printing

Once the equipment is set up, Screen Printers begin the printing process. They carefully load the substrate onto the machine and align it with the screen. They then apply the ink to the screen and squeegee it across the substrate, transferring the image to the surface.

- Load substrates onto the machine and align them with the screen

- Apply ink to the screen and squeegee it across the substrate

- Inspect printed materials for defects

3. Drying and Curing

After the printing process is complete, Screen Printers dry and cure the printed materials. This involves placing the materials in a drying oven or exposing them to ultraviolet light. This process helps to ensure that the ink is properly set and that the printed materials are durable.

- Place printed materials in a drying oven

- Expose printed materials to ultraviolet light

- Inspect dried and cured materials for defects

4. Quality Control

Screen Printers are responsible for maintaining quality control throughout the entire printing process. They inspect printed materials for defects and make sure that they meet the required specifications. They also work closely with customers to ensure that they are satisfied with the final product.

- Inspect printed materials for defects

- Ensure that printed materials meet the required specifications

- Work closely with customers to ensure satisfaction

Interview Tips

Preparing for an interview is essential for success. Here are some tips to help you ace your interview for a Screen Printer position:

1. Research the Company and the Position

Take the time to learn about the company you are interviewing with and the specific position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website and social media pages

- Read industry news and articles

- Talk to people who work or have worked at the company

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Brainstorm a list of potential interview questions

- Write out your answers and practice delivering them aloud

- Ask a friend or family member to conduct a mock interview

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a Screen Printer. Be prepared to discuss your previous work experience, as well as any relevant skills or training that you have.

- Highlight your experience in operating and maintaining screen printing equipment

- Describe your skills in preparing and setting up screens, printing, and drying and curing printed materials

- Mention any relevant certifications or training that you have

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and passionate about their work. Be sure to convey your interest in the position and the company during your interview. Show the interviewer that you are excited about the opportunity to learn and grow.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Be positive and enthusiastic

5. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the position or the company. This shows that you are interested and engaged, and that you are taking the interview seriously.

- Ask about the company’s culture and values

- Ask about the specific responsibilities of the position

- Ask about the company’s growth plans

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Screen Printer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.