Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Screen Printing Cloth Spreader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

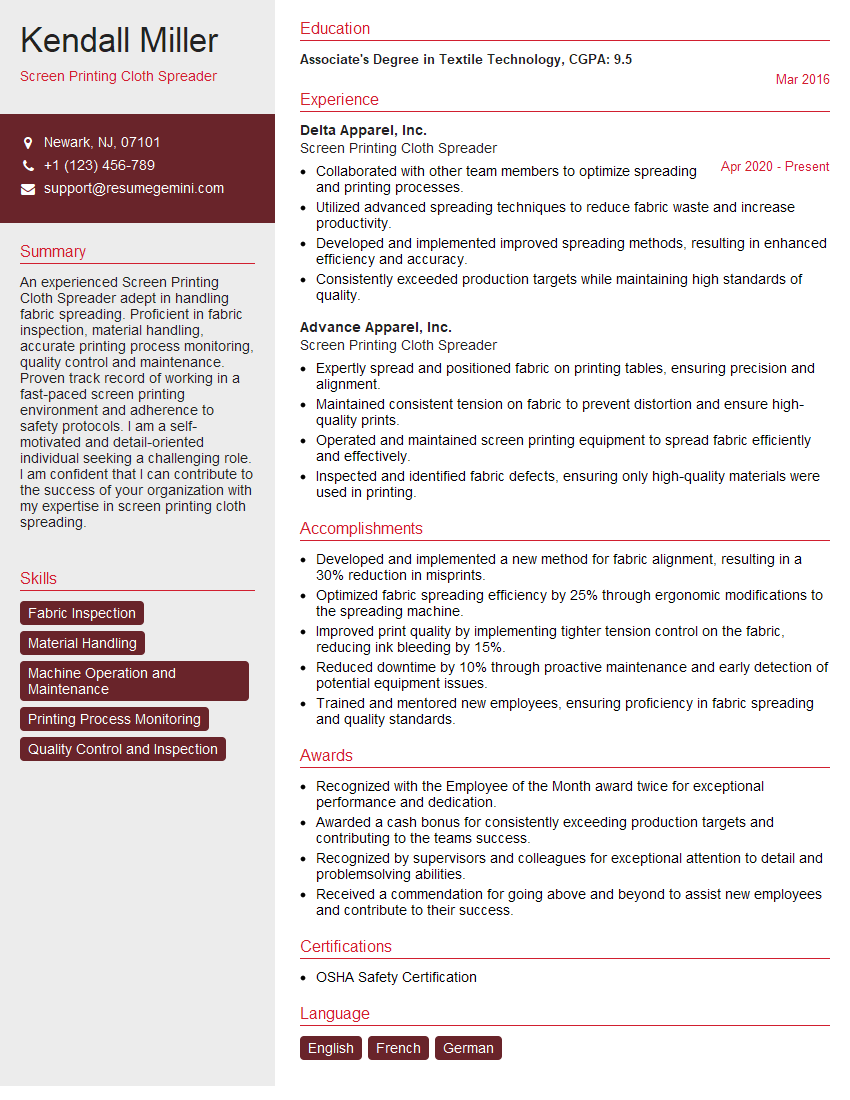

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Printing Cloth Spreader

1. How do you ensure accurate and consistent cloth spreading for screen printing?

To ensure accurate and consistent cloth spreading, I follow a meticulous process that involves:

- Calibrating the spreading machine regularly to maintain precise measurements and avoid fabric distortion.

- Inspecting the cloth before spreading to check for any defects, wrinkles, or inconsistencies that could affect print quality.

- Using tension bars or clamps to keep the fabric taut and prevent stretching or shrinking during the printing process.

- Monitoring the spreading speed and tension settings to ensure optimal fabric placement and print registration.

2. Describe your experience in operating different types of screen printing spreading machines.

Manual Spreading Machines

- Proficient in adjusting manual spreading machines for various fabric types and thicknesses.

- Skilled in manually aligning the cloth on the spreading table and ensuring even tension.

Semi-Automatic Spreading Machines

- Experienced in operating semi-automatic spreading machines with computerized controls for precise spreading and cutting.

- Familiar with using software to program spreading patterns and optimize fabric utilization.

Fully-Automatic Spreading Machines

- Trained in operating fully-automatic spreading machines that automate the entire spreading process, including fabric loading, spreading, and cutting.

- Capable of troubleshooting and maintaining these sophisticated machines independently.

3. How do you manage and minimize fabric waste during the spreading process?

To minimize fabric waste, I employ several strategies:

- Optimizing spreading patterns using software or manual calculations to reduce leftover fabric and maximize yield.

- Inspecting fabric rolls for any defects or irregularities before spreading to avoid wasting defective material.

- Reusing leftover fabric pieces for smaller prints or sampling purposes to minimize waste.

- Properly storing and handling fabric rolls to prevent damage and maintain fabric quality.

4. What safety precautions do you observe when working with screen printing spreading machines?

I prioritize safety by adhering to the following precautions:

- Wearing appropriate safety gear, such as gloves and safety glasses, to protect against potential hazards.

- Ensuring that the spreading machine is properly grounded and maintained to prevent electrical accidents.

- Keeping the work area clean and organized to minimize tripping or slipping hazards.

- Following lockout/tagout procedures before performing any maintenance or repairs.

- Reporting any safety concerns or potential hazards to supervisors immediately.

5. Describe your knowledge of different fabric types and their suitability for screen printing.

I am familiar with a wide range of fabric types and their specific requirements for screen printing:

- Natural fibers: Cotton, linen, wool, and silk have different absorption rates and require specific inks and treatments.

- Synthetic fibers: Polyester, nylon, and rayon need special pre-treatment and inks to ensure proper adhesion.

- Blended fabrics: Combinations of natural and synthetic fibers require careful consideration of both fiber characteristics.

- Specialty fabrics: Waterproof, fire-resistant, and stretch fabrics may necessitate modified spreading techniques and specialized inks.

6. How do you troubleshoot common issues that arise during the cloth spreading process?

I am adept at identifying and resolving common spreading issues:

- Wrinkled or uneven fabric: Adjusting tension settings, using wrinkle removers, or re-spreading the fabric.

- Fabric stretching or shrinking: Ensuring proper tension and using the correct spreading technique for the fabric type.

- Fabric loading errors: Checking the machine settings, ensuring proper fabric alignment, and recalibrating the spreading machine if necessary.

- Machine malfunctions: Following troubleshooting protocols, checking electrical connections, and replacing faulty components.

7. How do you work effectively as part of a production team in a screen printing environment?

I am a collaborative and efficient team player:

- Communicating effectively with other team members to ensure smooth production flow.

- Assisting with loading and unloading fabric rolls, maintaining equipment, and troubleshooting issues.

- Following production schedules and meeting deadlines while maintaining quality standards.

- Adapting to changing production demands and working under different time constraints.

8. What are your techniques for increasing productivity and efficiency in the cloth spreading process?

I implement various techniques to optimize productivity and efficiency:

- Using efficient spreading patterns and techniques to minimize fabric waste and reduce spreading time.

- Maintaining a clean and organized work area to prevent delays and distractions.

- Performing regular maintenance on the spreading machine to minimize downtime and ensure optimal performance.

- Identifying and addressing potential bottlenecks in the spreading process and implementing solutions.

9. How do you stay up-to-date with the latest advancements in screen printing spreading technology?

I remain informed about industry trends and technological advancements through:

- Attending industry trade shows and conferences.

- Reading industry publications and online forums.

- Participating in professional development courses and workshops.

- Consulting with equipment manufacturers and distributors.

10. Describe a challenging situation you faced in the past related to cloth spreading and how you overcame it.

In a previous role, we encountered an issue with fabric shrinkage during the spreading process. The fabric we were using had a tendency to shrink unevenly, leading to misalignment and printing errors. To resolve this, I conducted thorough testing to determine the optimal tension settings and spreading technique for that particular fabric. I also worked closely with the fabric supplier to identify any potential variations in the fabric quality. By implementing these measures, we were able to minimize shrinkage and ensure consistent print results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Printing Cloth Spreader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Printing Cloth Spreader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Screen Printing Cloth Spreader plays a crucial role in the textile industry, ensuring that fabric is prepared and positioned accurately for screen printing. Key responsibilities include:

1. Fabric Handling and Preparation

Inspect fabric for defects, measure and cut it to required dimensions, and prepare it for printing.

2. Spreading Fabric

Load fabric onto a spreading machine and adjust tension, ensuring it is spread evenly and without wrinkles or distortions.

3. Material alignment

Align fabric precisely with the screen printing equipment, using registration marks and other guides to ensure accurate placement.

4. Quality Control

Monitor the spreading process, check fabric quality, and make adjustments as needed to maintain standards.

Interview Tips

To ace an interview for the position of Screen Printing Cloth Spreader, it’s essential to showcase your skills and demonstrate enthusiasm for the role. Here are some preparation tips:

1. Research the Company and Industry

Learn about the company’s values, products, and industry trends. This knowledge will help you tailor your answers to the interviewer’s specific questions and demonstrate your interest in the company.

2. Highlight Experience and Skills

Emphasize your experience in fabric handling, spreading, and quality control. Quantify your accomplishments with specific examples to demonstrate your impact on the printing process.

3. Show Attention to Detail

Convey your meticulous approach to work by highlighting your ability to inspect fabric for defects, measure and cut it precisely, and align it accurately for printing.

4. Be Prepared for Technical Questions

Review common screen printing techniques, equipment, and fabric types. Be ready to answer questions about spreading different fabrics, aligning them with printing equipment, and ensuring optimal tension.

5. Practice and Prepare

Rehearse your answers to potential interview questions, including those related to your experience, skills, and knowledge of the industry. Confidence and preparation will make a positive impression.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Screen Printing Cloth Spreader role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.