Are you gearing up for an interview for a Screen Printing Equipment Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Screen Printing Equipment Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

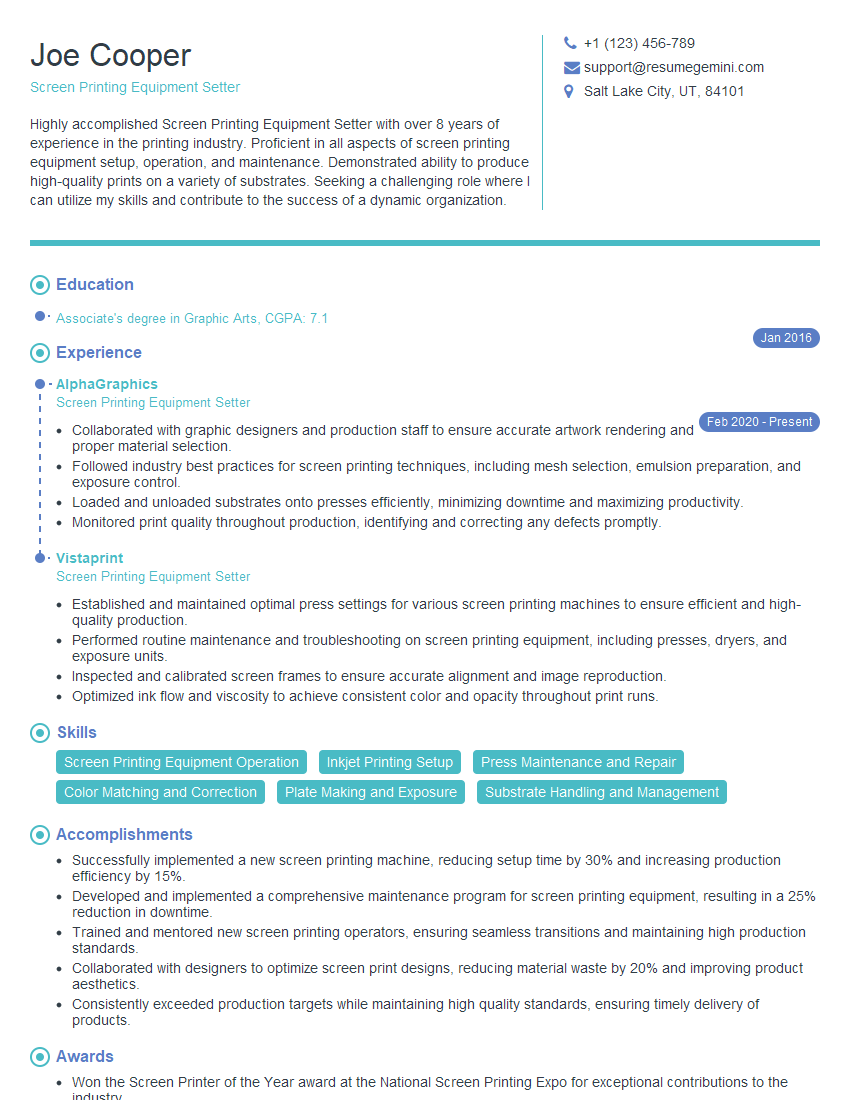

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Printing Equipment Setter

1. Describe the key responsibilities of a Screen Printing Equipment Setter.

As a Screen Printing Equipment Setter, I am responsible for:

- Preparing and setting up screen printing equipment, including presses, screens, and inks.

- Calibrating and maintaining equipment to ensure optimal printing quality.

- Loading and unloading printed materials.

- Monitoring the printing process and making adjustments as needed.

2. What are the different types of screen printing presses and their main features?

Flatbed Presses

- Used for printing on flat surfaces, such as textiles, paper, and metal.

- Offers high precision and accuracy.

- Suitable for short to medium print runs.

Rotary Presses

- Designed for high-volume printing on fabrics and other roll materials.

- Continuous printing process allows for fast production rates.

- Requires specialized skills and experience to operate.

3. Explain the process of screen printing from start to finish.

The screen printing process involves the following steps:

- Creating a design and preparing the screen.

- Coating the screen with light-sensitive emulsion.

- Exposing the screen to UV light through the design.

- Washing out the unexposed areas of the emulsion.

- Applying ink to the screen and printing the design onto the material.

4. What quality control measures are essential in screen printing?

To ensure high-quality screen printing, it is crucial to implement the following quality control measures:

- Inspecting screens for defects.

- Checking ink viscosity and color accuracy.

- Testing printed samples for print quality.

- Regularly cleaning and maintaining equipment.

- Following established quality control protocols.

5. What are the common challenges faced by Screen Printing Equipment Setters and how do you overcome them?

As a Screen Printing Equipment Setter, I have encountered various challenges, including:

- Screen defects: Identifying and correcting defects in screens to ensure consistent print quality.

- Ink problems: Troubleshooting and resolving issues with ink viscosity, color matching, and drying time.

- Equipment failures: Diagnosing and repairing equipment malfunctions to minimize downtime.

6. How do you ensure proper registration in screen printing?

Maintaining proper registration is essential for accurate printing. I ensure it by:

- Using registration marks on screens and materials.

- Adjusting the press settings to align the screens precisely.

- Inspecting printed materials for registration errors and making necessary adjustments.

7. Describe your experience with different screen printing inks and their properties.

I have worked with various screen printing inks, including:

- Water-based inks: Environmentally friendly, easy to clean up, and suitable for printing on fabrics.

- Solvent-based inks: Durable, resistant to water and chemicals, and often used for industrial applications.

- UV-curable inks: Dry instantly under UV light, allowing for fast production and high-quality prints.

8. What maintenance procedures do you perform on screen printing equipment?

To keep equipment running smoothly, I regularly perform the following maintenance procedures:

- Cleaning and inspecting screens.

- Lubricating moving parts.

- Checking and replacing worn or damaged components.

- Following manufacturer’s recommended maintenance schedules.

9. How do you work effectively in a fast-paced screen printing environment?

In fast-paced screen printing environments, I prioritize and manage my tasks efficiently. I:

- Plan and prepare: Anticipate production needs and prepare materials in advance.

- Prioritize tasks: Identify and focus on critical tasks to maximize productivity.

- Stay organized: Maintain a clean and organized workspace to minimize errors and downtime.

10. What safety precautions should be taken when operating screen printing equipment?

Ensuring safety is paramount in screen printing operations. I strictly adhere to the following precautions:

- Wear appropriate PPE: Use gloves, masks, and safety glasses to protect against chemicals and debris.

- Follow lockout/tagout procedures: Ensure equipment is isolated during maintenance or repairs.

- Maintain a clean and well-ventilated work area: Remove flammable materials and minimize the risk of accidents.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Printing Equipment Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Printing Equipment Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Screen Printing Equipment Setters are responsible for setting up and maintaining screen printing equipment. They ensure that the equipment is running smoothly and efficiently, and that the printed products meet the required quality standards. Some of their key responsibilities include:

1. Preparing the Printing Press

Setting up the printing press involves various tasks, such as:

- Selecting the appropriate screens for the job.

- Installing the screens on the press.

- Adjusting the press settings (e.g., print speed, ink flow, pressure, etc.) according to the print job requirements.

2. Mixing and Preparing Inks

Screen Printing Equipment Setters are responsible for mixing and preparing inks to achieve the desired color and consistency. This task requires:

- Selecting the appropriate inks for the printing job.

- Measuring and mixing inks according to specific formulas.

- Adjusting ink viscosity to ensure optimal printability.

3. Operating the Printing Press

Operating the printing press involves:

- Loading the substrate (e.g., paper, fabric, etc.) onto the press.

- Adjusting the press speed and print settings to achieve the desired print quality.

- Monitoring the printing process to ensure consistent results.

4. Maintaining the Printing Equipment

Screen Printing Equipment Setters are also responsible for maintaining the printing equipment in good working condition. This includes:

- Cleaning and inspecting the printing press, screens, and other components regularly.

- Performing routine maintenance tasks, such as lubricating moving parts and replacing worn-out components.

- Troubleshooting and resolving any equipment issues that may arise during printing.

Interview Tips

Preparing well for an interview can increase your chances of making a good impression and landing the job. Here are some tips to help you ace an interview for a Screen Printing Equipment Setter position:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and business goals. It will also allow you to tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Prepare your answers to these questions in advance and practice delivering them in a clear and concise manner.

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience. This includes any experience you have in screen printing, as well as any transferable skills that you may have, such as problem-solving, attention to detail, and teamwork.

4. Be Enthusiastic and Positive

Interviewers are more likely to be impressed by candidates who are enthusiastic and positive about the position. Show the interviewer that you are genuinely interested in the job and that you are confident in your abilities. Be prepared to talk about why you are passionate about screen printing and why you believe you would be a good fit for the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Screen Printing Equipment Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.