Are you gearing up for an interview for a Screen Printing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Screen Printing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

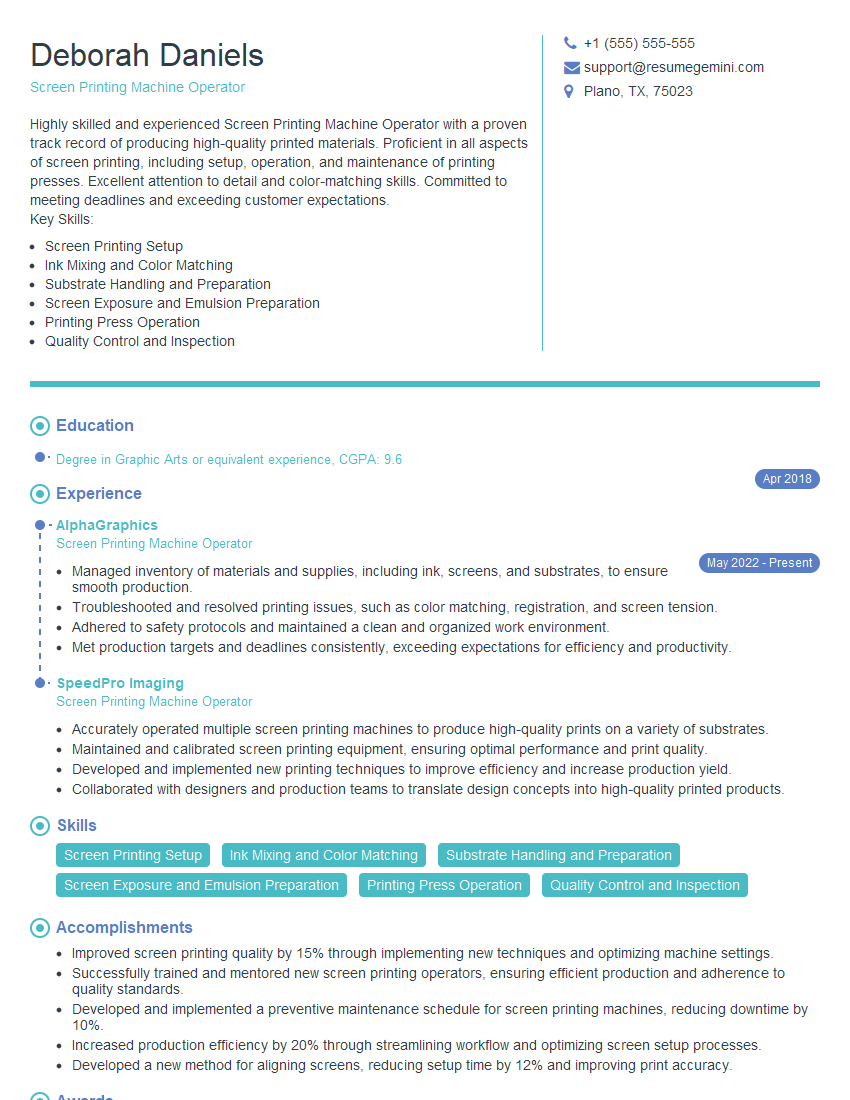

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Printing Machine Operator

1. Explain the process of screen printing, including the preparation of screens, mixing of inks, and printing techniques?

The screen printing process involves several key steps:

- Screen Preparation: A fine mesh is stretched over a frame to create a screen. A light-sensitive emulsion is applied to the screen, and a film positive of the desired image is placed on top. The screen is exposed to light, which hardens the emulsion in areas not covered by the film. This creates a stencil on the screen.

- Ink Mixing: Screen printing inks come in a variety of colors and formulations. The ink is mixed to the desired consistency and opacity.

- Printing: The screen is placed over the substrate (the material being printed on). Ink is applied to the top of the screen and forced through the stencil onto the substrate using a squeegee. The substrate is then dried or cured to set the ink.

2. Describe the different types of screen printing machines, their capabilities and applications?

Manual Screen Printing Machines:

- Suitable for small-scale or hobbyist printing.

- Requires manual operation of the squeegee.

- Versatile and can print on a variety of substrates.

Semi-Automatic Screen Printing Machines:

- Partially automated, with electric or pneumatic squeegee operation.

- Faster and more consistent than manual machines.

- Capable of printing larger volumes.

Automatic Screen Printing Machines:

- Fully automated, with all operations controlled by a computer.

- Highly efficient and can produce large print volumes.

- Suitable for mass production.

3. How do you maintain and troubleshoot screen printing machines?

Regular maintenance is crucial to ensure optimal performance:

- Daily: Clean screens and squeegees, check ink levels, and inspect the machine for any visible issues.

- Weekly: Perform a thorough cleaning of the machine, including the ink system, print heads, and conveyor belt.

- Monthly: Conduct a comprehensive inspection, check for loose or worn parts, and lubricate moving components.

- Troubleshooting: Common issues include screen clogging, misalignment, ink smearing, and print quality problems. Identify the root cause and implement appropriate solutions.

4. What are the key factors that affect the quality of screen printing?

- Screen Mesh Count: The mesh size determines the detail and sharpness of the printed image.

- Ink Viscosity: The thickness of the ink affects how it flows through the screen and the opacity of the print.

- Squeegee Pressure and Angle: The amount of pressure and angle at which the squeegee is applied impacts the ink transfer and print quality.

- Substrate Preparation: The surface of the substrate must be clean and properly treated to ensure good ink adhesion.

- Curing Process: The temperature and duration of the curing process determine the durability and colorfastness of the print.

5. How do you handle production deadlines under pressure?

Time management and prioritization are key:

- Plan and Schedule: Break down the task into smaller, manageable steps and allocate time accordingly.

- Prioritize Tasks: Focus on completing the most critical tasks first.

- Delegate and Communicate: If possible, delegate tasks to others and keep stakeholders informed of progress.

- Stay Organized: Maintain a well-organized workspace and keep track of deadlines.

- Stay Calm Under Pressure: Maintain composure and focus on finding solutions to challenges.

6. Describe your experience in working with different types of fabrics and substrates?

I have experience printing on a wide range of fabrics, including cotton, polyester, nylon, and blends. I am also familiar with printing on non-fabric substrates such as paper, metal, and plastic.

7. What are the safety precautions you take when working with screen printing machines and materials?

- Wear appropriate PPE: Safety glasses, gloves, and a mask to protect against chemicals.

- Handle chemicals properly: Follow safety instructions and store chemicals securely.

- Maintain a clean workspace: Reduce the risk of accidents and ensure proper ventilation.

- Be aware of machine hazards: Understand the potential risks and operate machines safely.

- Follow established protocols: Adhere to safety regulations and guidelines.

8. How do you stay up-to-date with advancements in screen printing technology?

- Attend industry events: Trade shows and conferences provide opportunities to learn about new technologies.

- Read trade publications: Stay informed about industry trends and best practices.

- Online research: Utilize online resources to explore new technologies and techniques.

9. Describe a challenging project you have worked on as a screen printing machine operator?

I once worked on a project where we had to print a complex design on a large volume of T-shirts with a tight deadline. We faced challenges with maintaining consistent ink flow and preventing smudging. To overcome these challenges, I adjusted the squeegee pressure and angle, experimented with different ink viscosities, and implemented a meticulous drying process.

10. Why are you interested in working as a screen printing machine operator for our company?

I am eager to join your company because I am passionate about screen printing and I believe my skills and experience would be a valuable asset to your team. I am particularly interested in your company’s commitment to quality and innovation, and I am excited about the opportunity to contribute to your success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Printing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Printing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Screen Printing Machine Operator plays a crucial role in the production of printed materials, utilizing specialized equipment to create high-quality prints.

1. Screen Setup and Maintenance

Responsible for preparing and maintaining screen printing machines, ensuring optimal performance.

- Set up and align screens accurately to achieve precise registration and print quality.

- Clean and maintain screens regularly to prevent ink clogging and ensure consistent printing.

2. Ink Preparation and Application

Mix and prepare inks according to specified formulas, ensuring proper viscosity and color accuracy.

- Apply inks to screens using squeegees or automatic applicators, controlling pressure and speed for optimal results.

- Monitor ink levels and replenish as needed.

3. Substrate Handling

Load and unload various substrates, such as fabrics, paper, or plastics, onto the printing machine.

- Ensure proper alignment and tension of substrates to prevent printing errors.

- Inspect substrates for defects or irregularities before printing.

4. Quality Control

Inspect printed materials for defects, such as smudging, misalignment, or color variations.

- Identify and troubleshoot printing issues promptly to maintain high standards.

- Calibrate and adjust equipment to ensure accurate and consistent prints.

Interview Tips

Preparing thoroughly for a Screen Printing Machine Operator interview can significantly increase your chances of success. Here are some tips and hacks to help you ace it:

1. Research the Company

Familiarize yourself with the company’s history, products, and culture. Learn about their printing capabilities and target market. This knowledge will show the interviewer that you are genuinely interested in the role and the company.

- Visit the company’s website and social media pages.

- Read industry articles and news about the company.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers. Focus on highlighting your skills, experience, and enthusiasm for screen printing. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Example: Describe a challenging printing project you successfully completed.

- Example: How do you ensure the accuracy and quality of your prints?

3. Showcase Your Technical Skills

Emphasize your proficiency in screen printing techniques, including screen setup, ink preparation, and substrate handling. Quantify your accomplishments and provide specific examples to demonstrate your abilities.

- Example: “I have consistently exceeded production targets by 15% through efficient screen setup and ink optimization.”

- Example: “I developed a new technique for handling delicate fabrics that resulted in reduced waste and improved print quality.”

4. Highlight Your Problem-Solving Abilities

Screen printing often involves troubleshooting and problem-solving. Share instances where you identified and resolved printing issues effectively. Describe your analytical approach and the steps you took to improve processes.

- Example: “I diagnosed a registration problem by examining the screen alignment and ink viscosity. After making adjustments, the print quality improved significantly.”

- Example: “I implemented a new ink drying system that reduced curing time by 30%, resulting in increased production efficiency.”

5. Demonstrate Your Passion for Screen Printing

Convey your enthusiasm for the craft of screen printing. Explain why you are fascinated by the process and how you strive for excellence in every print you create.

- Example: “I find the precision and artistry of screen printing incredibly satisfying. I am always exploring new techniques to enhance the quality and impact of my work.”

- Example: “I am passionate about collaborating with designers and artists to bring their visions to life through screen printing.”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Screen Printing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.