Are you gearing up for an interview for a Screw Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Screw Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

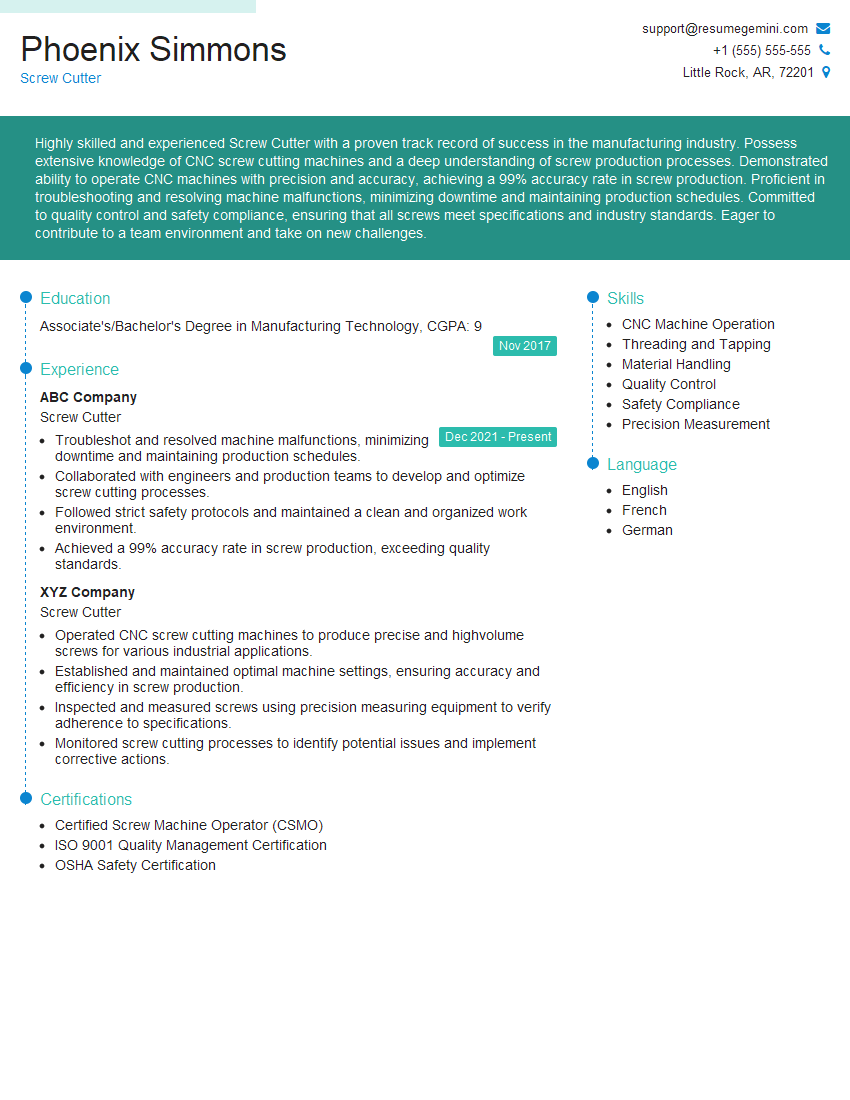

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screw Cutter

1. What are the different types of screw cutters available?

There are various types of screw cutters available, each designed for specific applications. Some of the most common types include:

- Flat-head screwdriver: Used for screws with flat head slots.

- Phillips screwdriver: Used for screws with cross-shaped head slots.

- Hex screwdriver: Used for screws with hexagonal head slots.

- Robertson screwdriver: Used for screws with square head slots.

- Torx screwdriver: Used for screws with star-shaped head slots.

2. What are the key factors to consider when selecting a screw cutter?

Material:

- The material of the screw cutter is crucial because it affects its durability and performance.

- Common materials include hardened steel, chrome-vanadium steel, and stainless steel.

Size and shape:

- The size and shape of the screw cutter must match the screw head it is intended to be used with.

- Using the wrong size or shape can damage the screw or the cutter.

Handle:

- The handle of the screw cutter should be comfortable to hold and provide a secure grip.

- Ergonomic handles can reduce fatigue and improve control.

3. What are the safety precautions to observe when using a screw cutter?

Safety is paramount when using a screw cutter. Some critical precautions include:

- Wear safety glasses to protect eyes from flying debris or metal splinters.

- Ensure the screw cutter is the right size and shape for the screw being used.

- Apply force in a straight line to avoid bending or breaking the cutter.

- Never use a damaged or defective screw cutter.

4. How do you sharpen a screw cutter?

Sharpening a screw cutter is essential to maintain its effectiveness. The process involves using a sharpening stone or a grinding wheel.

- Hold the screw cutter at a slight angle to the stone or wheel.

- Apply gentle pressure and move the cutter back and forth across the abrasive surface.

- Maintain a consistent angle and avoid overheating the cutter.

5. What is the difference between a screw cutter and a screwdriver?

Screw cutters and screwdrivers are both tools used to drive screws, but they have distinct differences:

- Screw cutters are designed for heavy-duty applications and can withstand high torque.

- Screwdrivers, on the other hand, are typically used for lighter tasks and provide less torque.

- Screw cutters have interchangeable blades, while screwdrivers usually have fixed bits.

6. What are the common materials used to make screw cutters?

- Hardened steel: Provides durability and strength for demanding applications.

- Chrome-vanadium steel: Offers a combination of strength, toughness, and corrosion resistance.

- Stainless steel: Resists corrosion and is suitable for use in wet or harsh environments.

7. What are the key features to look for when purchasing a screw cutter?

Durability:

- The screw cutter should be made from high-quality materials to ensure longevity.

Versatility:

- Consider screw cutters with interchangeable blades to handle various screw sizes and types.

Ergonomics:

- Choose a screw cutter with a comfortable handle to reduce fatigue during prolonged use.

8. How do you ensure the safety of others when using screw cutters?

- Wear appropriate safety gear, including safety glasses and gloves.

- Inspect the screw cutter before each use to ensure it is in good condition.

- Keep the work area clear of obstacles and potential hazards.

9. What are some maintenance tips for screw cutters?

Cleaning:

- Wipe down the screw cutter with a clean cloth after use.

Sharpening:

- Sharpen the screw cutter regularly using a sharpening stone or a grinding wheel.

Storage:

- Store the screw cutter in a dry place to prevent rust.

10. Can you describe the process of threading a screw using a screw cutter?

Preparation:

- Select the correct screw cutter for the screw size and material.

- Secure the workpiece firmly in a vise or other holding device.

Threading:

- Hold the screw cutter perpendicular to the workpiece.

- Apply downward pressure and rotate the screw cutter clockwise.

- Continue rotating and applying pressure until the desired thread depth is achieved.

Finishing:

- Remove the screw cutter and inspect the threads.

- Clean the threads with a wire brush or a tap.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screw Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screw Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Screw Cutters are responsible for operating and maintaining screw cutting machines to create screws and other threaded components. They ensure that the machines are operating correctly and that the finished products meet the required specifications.

1. Machine Operation

Screw Cutters are responsible for setting up and operating screw cutting machines. This includes loading the raw material, adjusting the machine settings, and monitoring the cutting process. They must also be able to troubleshoot any problems that may occur during operation.

- Load and unload raw materials

- Adjust machine settings according to specifications

- Monitor the cutting process to ensure that it meets specifications

- Troubleshoot and resolve any problems that may occur during operation

2. Product Inspection

Screw Cutters are responsible for inspecting the finished products to ensure that they meet the required specifications. This includes checking the dimensions, thread quality, and surface finish. They must also be able to identify any defects or imperfections.

- Inspect finished products to ensure that they meet specifications

- Check dimensions, thread quality, and surface finish

- Identify any defects or imperfections

3. Machine Maintenance

Screw Cutters are responsible for maintaining the screw cutting machines. This includes cleaning, lubricating, and adjusting the machines as needed. They must also be able to identify any potential problems and take steps to prevent them from occurring.

- Clean, lubricate, and adjust the machines as needed

- Identify any potential problems and take steps to prevent them from occurring

4. Quality Control

Screw Cutters are responsible for ensuring that the finished products meet the required quality standards. This includes inspecting the products, maintaining the machines, and following quality control procedures. They must also be able to identify any areas where improvements can be made.

- Inspect the products to ensure that they meet quality standards

- Maintain the machines to ensure that they are operating correctly

- Follow quality control procedures

- Identify any areas where improvements can be made

Interview Tips

Preparing for a job interview can be stressful, but there are some things you can do to improve your chances of success. Here are a few tips to help you ace your interview for a Screw Cutter position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you answer questions about the position and why you are interested in it.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is a good idea to practice your answers to these questions ahead of time. This will help you feel more confident and prepared during your interview.

- Prepare a brief introduction of yourself

- Explain why you are interested in the position

- Highlight your skills and experience that are relevant to the position

3. Dress appropriately

First impressions matter, so it is important to dress appropriately for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. You should also avoid wearing too much jewelry or perfume.

- Wear clean, pressed clothes

- Dress in a way that is appropriate for the office environment

- Avoid wearing too much jewelry or perfume

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call the interviewer to let them know. It is also a good idea to arrive a few minutes early so that you have time to check in and get settled.

- Arrive for your interview on time

- If you are running late, call the interviewer to let them know

- Arrive a few minutes early so that you have time to check in and get settled

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Screw Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!