Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Screw Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

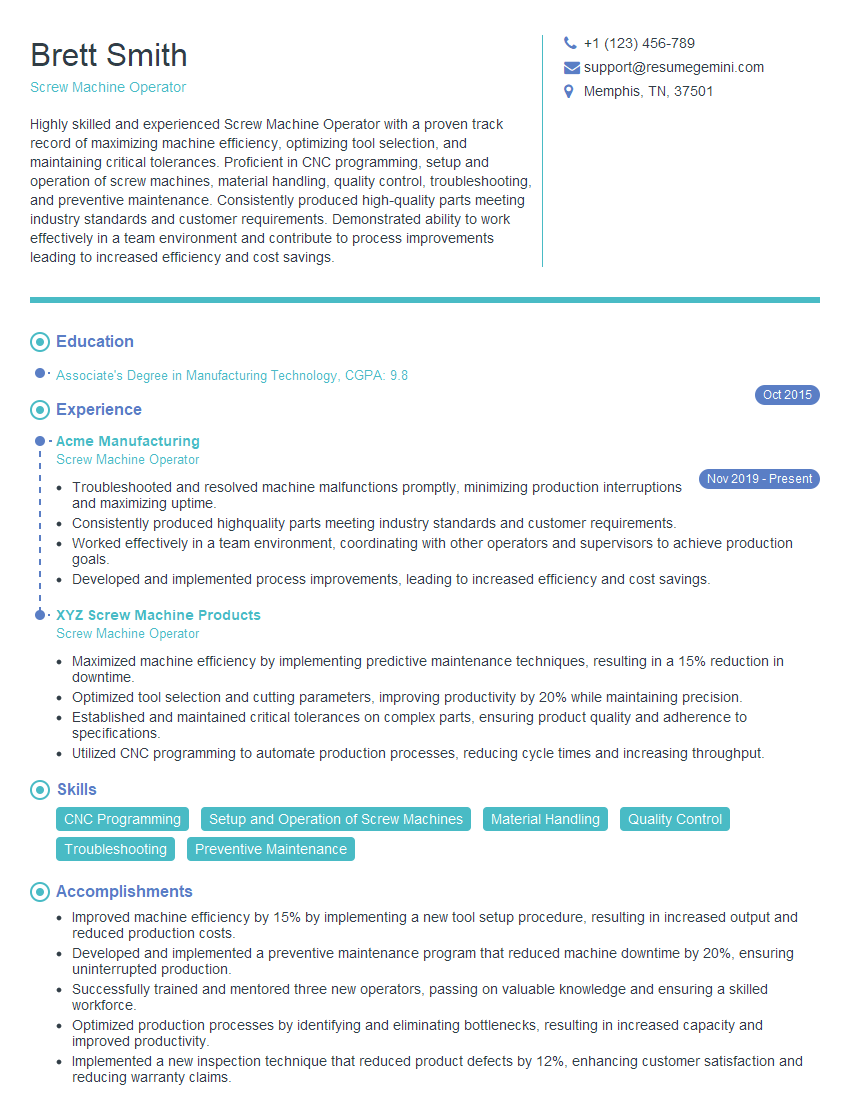

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screw Machine Operator

1. Explain the process of setting up a CNC screw machine for a new job?

- First, I would check the job specifications to determine the required materials, tools, and settings.

- Next, I would load the raw material into the machine and secure it in the chuck.

- I would then select the appropriate tooling and insert it into the turret.

- Finally, I would program the machine using the CNC control panel, entering the necessary codes and parameters to create the desired part.

2. What are the different types of materials that can be machined on a screw machine?

Metals

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

Plastics

- Acetal

- Nylon

- Polycarbonate

- Polyethylene

- Polypropylene

3. What are the different types of operations that can be performed on a screw machine?

- Turning

- Drilling

- Boring

- Knurling

- Threading

- Milling

4. What are the safety precautions that must be taken when operating a screw machine?

- Always wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep your hands away from moving parts.

- Never operate the machine while under the influence of drugs or alcohol.

- Be aware of the machine’s surroundings and keep it clear of obstacles.

- Follow all manufacturer’s instructions for safe operation.

5. What are the different types of cutting tools used on a screw machine?

- Single-point cutting tools

- Multi-point cutting tools

- Carbide cutting tools

- High-speed steel cutting tools

- Diamond cutting tools

6. What are the different speeds and feeds that can be used on a screw machine?

The speeds and feeds that can be used on a screw machine will vary depending on the material being machined, the type of cutting tool being used, and the desired finish. In general, higher speeds and feeds will result in a faster machining time, but may also result in a rougher finish. Lower speeds and feeds will result in a slower machining time, but may also result in a smoother finish.

7. What are the different types of coolants used on a screw machine?

- Water-based coolants

- Oil-based coolants

- Synthetic coolants

8. What are the different types of chips that can be produced on a screw machine?

- Continuous chips

- Discontinuous chips

- Serrated chips

- Built-up edge chips

9. What are the different types of finishes that can be achieved on a screw machine?

- Rough finish

- Semi-finish

- Finish

- Superfinish

10. What are the different types of quality control checks that can be performed on a screw machine?

- Visual inspection

- Dimensional inspection

- Surface finish inspection

- Hardness testing

- Strength testing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screw Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screw Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Screw Machine Operators are responsible for operating screw machines to produce precision parts. Their primary duties include:

1. Machine Setup and Operation

– Interpreting engineering drawings and work orders to determine part specifications. – Setting up and calibrating screw machines, including selecting and installing cutting tools. – Loading raw materials and operating machines to produce parts. – Monitoring machine operation and making adjustments as needed to ensure accuracy and quality.

2. Inspection and Quality Control

– Inspecting finished parts to ensure they meet specifications. – Using measuring tools and gauges to verify dimensions and tolerances. – Identifying and correcting any defects or non-conformities. – Maintaining quality records and reporting any discrepancies.

3. Machine Maintenance

– Performing routine maintenance and cleaning on screw machines. – Identifying and troubleshooting mechanical and electrical problems. – Replacing worn or damaged components. – Lubricating and adjusting machines as per maintenance schedules.

4. Production Optimization

– Analyzing production schedules and identifying bottlenecks. – Implementing process improvements to enhance efficiency and reduce downtime. – Collaborating with engineers and supervisors to optimize machine settings and tooling. – Monitoring production output and reporting any deviations from targets.

Interview Tips

To ace an interview for a Screw Machine Operator position, it is crucial to prepare effectively and present your skills and experience in a compelling manner. Here are some tips to help you succeed:

1. Research the Company and Position

– Visit the company website to learn about their products, services, and culture. – Review the job description thoroughly and identify the key responsibilities and qualifications. – Research the industry and stay updated on the latest trends in screw machine operation.

2. Practice Your Skills and Knowledge

– Brush up on your math skills, especially trigonometry and geometry. – Review your understanding of mechanical principles and machine operation. – Familiarize yourself with different types of screw machines and cutting tools. – Practice reading engineering drawings and interpreting work orders.

3. Prepare for Common Interview Questions

– Example Outline: – Tell me about your experience as a Screw Machine Operator. – Describe a time when you successfully troubleshooted a problem with a screw machine. – How do you ensure the quality and accuracy of finished parts? – What are some techniques you use to improve production efficiency? – What are your strengths and weaknesses as a Screw Machine Operator?

4. Highlight Your Precision and Attention to Detail

– Emphasize your ability to produce high-quality parts with precision and accuracy. – Provide examples of how you have maintained strict tolerances and met customer specifications. – Showcase your attention to detail and your commitment to delivering flawless products.

5. Demonstrate Your Problem-Solving Skills

– Share experiences where you successfully diagnosed and resolved mechanical or electrical issues with screw machines. – Explain your approach to troubleshooting and how you prioritize solutions. – Highlight your ability to think critically and find innovative ways to overcome challenges.

6. Ask Relevant Questions

– At the end of the interview, ask thoughtful questions about the company, the position, and the training and support provided. – This shows your interest and engagement and allows you to gather more information about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Screw Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!