Are you gearing up for an interview for a Screw Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Screw Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

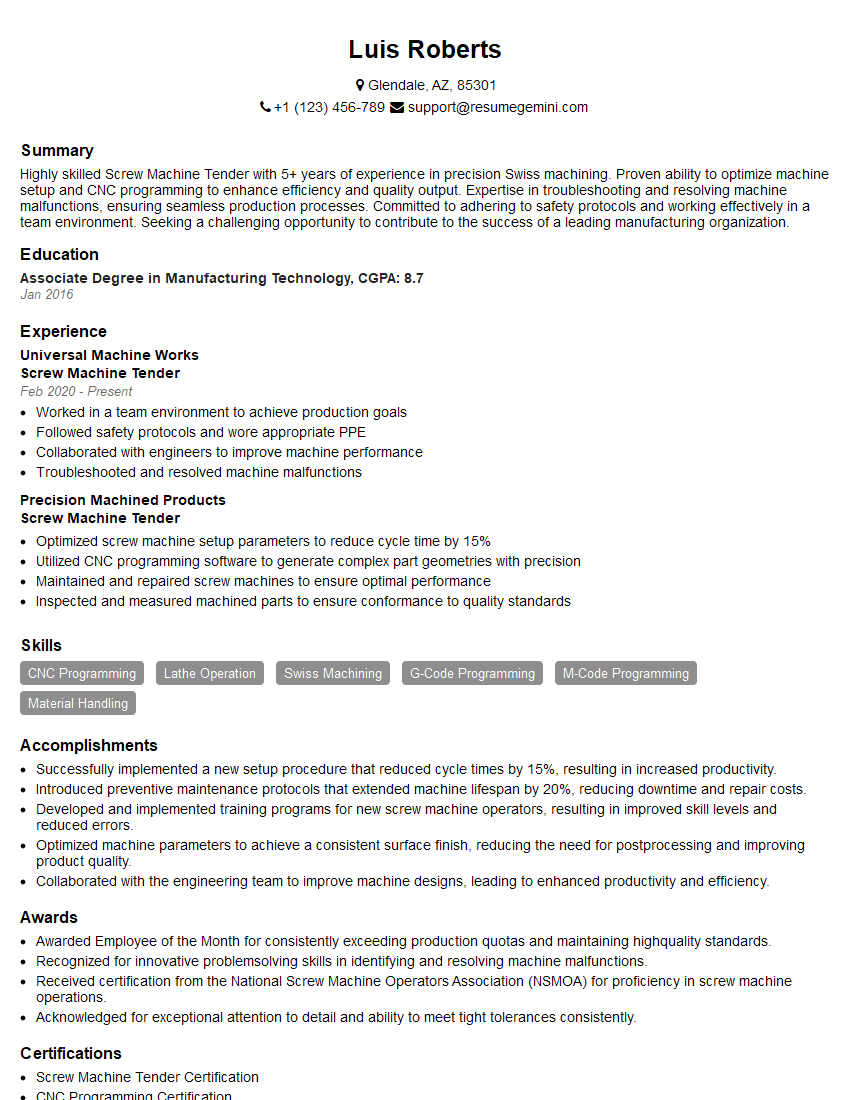

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screw Machine Tender

1. What are the key responsibilities of a Screw Machine Tender?

As a Screw Machine Tender, I would be responsible for:

- Setting up and operating screw machines to produce parts according to specifications.

- Monitoring machines and making adjustments as needed to ensure optimal performance and product quality.

- Inspecting and measuring finished parts to ensure they meet quality standards.

- Following safety protocols and procedures to maintain a safe work environment.

- Performing routine maintenance and troubleshooting on screw machines to minimize downtime.

2. What types of materials can you machine on a screw machine?

I have experience machining a wide range of materials on screw machines, including:

Metals:

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

Plastics:

- ABS

- Nylon

- Polyethylene

- Polypropylene

- PVC

3. What is the most challenging part of being a Screw Machine Tender?

The most challenging part of being a Screw Machine Tender is maintaining high levels of precision and accuracy while working at a fast pace. Screw machines can operate at very high speeds, and it is essential to be able to make quick adjustments and monitor the machine closely to ensure that parts are produced to the required specifications. Additionally, working with different materials and tools requires flexibility and a strong understanding of machining principles.

4. What are some of the safety precautions that you must take when operating a screw machine?

When operating a screw machine, it is essential to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Ensure that the machine is properly grounded and that all guards and shields are in place.

- Keep the work area clean and free of debris.

- Never reach into the machine while it is running.

- Be aware of the location of the emergency stop button and know how to use it.

5. How do you troubleshoot a screw machine that is not producing parts to specification?

When troubleshooting a screw machine that is not producing parts to specification, I would follow these steps:

- Check the machine settings to ensure that they are correct for the material and part being produced.

- Inspect the cutting tools for wear or damage and replace or sharpen them as needed.

- Check the workpiece for any defects or irregularities that may be affecting the machining process.

- Examine the machine for any mechanical problems that may be causing the issue.

- Consult with a supervisor or experienced machinist for additional assistance if necessary.

6. What is your experience with CNC screw machines?

I have extensive experience operating CNC screw machines. I am proficient in programming and operating these machines to produce complex parts with high precision and accuracy. I am also familiar with the various types of CNC controls and software used in the industry.

7. What is the difference between a single-spindle and a multi-spindle screw machine?

A single-spindle screw machine has one spindle that holds the workpiece, while a multi-spindle screw machine has multiple spindles that can hold multiple workpieces simultaneously. Multi-spindle screw machines are more efficient for producing large volumes of parts, as they can complete multiple operations on different parts at the same time.

8. What are some of the common problems that you encounter when operating a screw machine?

Some of the common problems that I encounter when operating a screw machine include:

- Tool wear or damage

- Workpiece defects or irregularities

- Mechanical problems with the machine

- Incorrect machine settings

- Material handling issues

9. How do you maintain a screw machine to ensure optimal performance?

To maintain a screw machine to ensure optimal performance, I would perform the following tasks:

- Regularly clean and lubricate the machine

- Inspect and replace cutting tools as needed

- Check and adjust machine settings as necessary

- Monitor the machine for any signs of wear or damage

- Perform preventive maintenance as recommended by the manufacturer

10. What is your experience with quality control in screw machining?

I have a strong understanding of quality control in screw machining, and I am experienced in using various inspection techniques and equipment to ensure that parts meet the required specifications. I am also familiar with ISO 9001 and other quality standards, and I am committed to producing high-quality products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screw Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screw Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Screw Machine Tenders are skilled manufacturing professionals responsible for operating screw machine, setting up and adjusting machines, and ensuring production goals are met. Their key job responsibilities encompass the following areas:

1. Machine Operation

Operate screw machines to produce a variety of metal parts, including shafts, bolts, and screws.

- Set up and adjust machines according to blueprints and specifications

- Load and unload raw materials and finished parts

- Monitor machine operation and make adjustments as needed

2. Quality Control

Inspect and measure finished parts to ensure they meet quality standards

- Use precision measuring equipment, such as calipers and micrometers

- Identify and correct any defects or errors

- Maintain quality control records

3. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting on screw machines

- Lubricate and clean machines

- Identify and fix minor problems

- Report major problems to supervisors

4. Safety and Compliance

Follow all safety regulations and procedures

- Wear appropriate safety gear

- Operate machines in a safe manner

- Maintain a clean and organized work area

Interview Tips

To ace an interview for a Screw Machine Tender position, it’s essential to prepare thoroughly and demonstrate your skills and qualifications. Here are some tips to help you:

1. Research the company and position

Familiarize yourself with the company’s products, services, and industry. Review the job description carefully to identify the specific skills and experience they are looking for.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Contact the hiring manager or recruiter with any questions

2. Practice common interview questions

Prepare for common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”. Practice answering these questions in a clear and concise manner, highlighting your relevant skills and experience.

- Use the STAR method to answer behavioral questions (Situation, Task, Action, Result)

- Tailor your answers to the specific job description

- Be confident and enthusiastic in your responses

3. Highlight your technical skills

Emphasize your technical skills in operating screw machines, inspecting parts, and performing maintenance. Provide specific examples of your experience and accomplishments.

- Quantify your results whenever possible

- Be prepared to discuss your knowledge of different types of screw machines

- Show your willingness to learn new skills and technologies

4. Demonstrate your safety awareness

Stress your commitment to safety and compliance. Describe your experience with safety regulations and procedures.

- Explain how you have maintained a safe work environment in previous roles

- Discuss your understanding of the importance of following safety protocols

- Be prepared to discuss your knowledge of specific safety regulations

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Screw Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Screw Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.