Feeling lost in a sea of interview questions? Landed that dream interview for Screw Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Screw Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

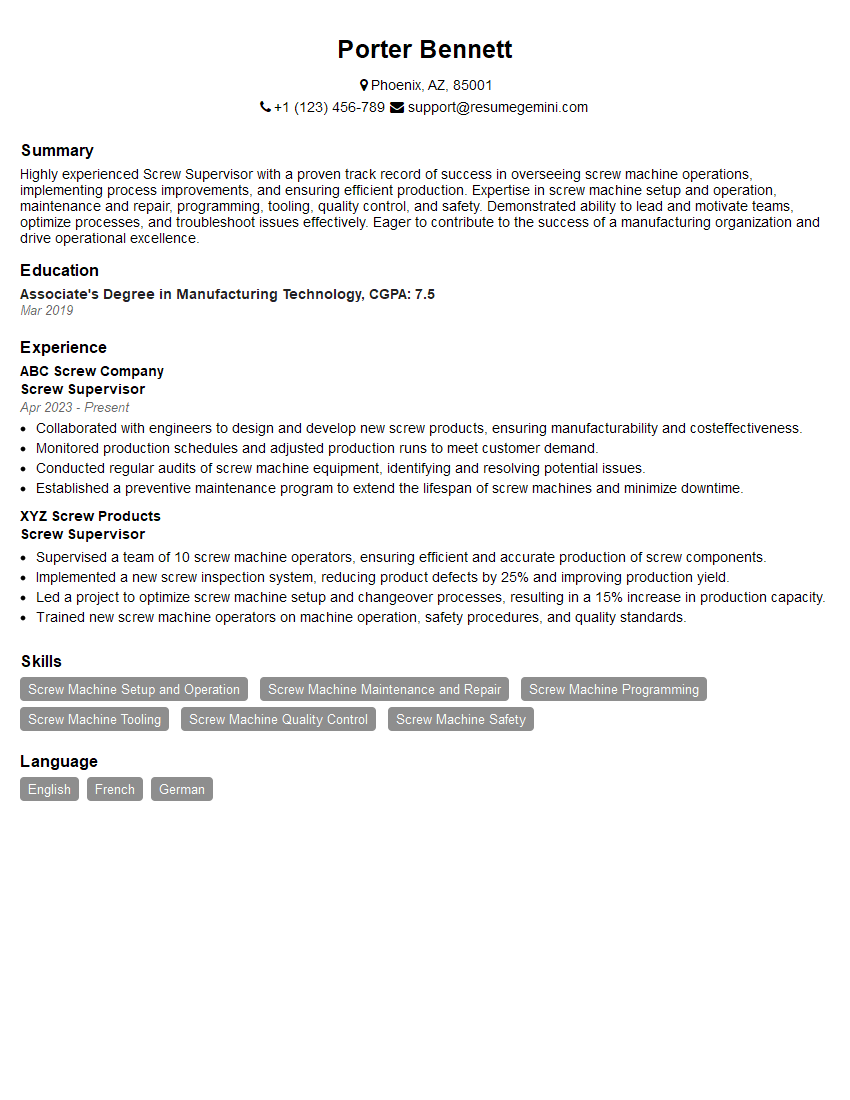

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screw Supervisor

1. How do you ensure the quality of screw assembly processes in your previous role?

In my previous role as a Screw Supervisor, I was responsible for ensuring the quality of screw assembly processes by implementing and maintaining a comprehensive quality management system. This involved:

- Establishing clear quality standards and specifications for screw assemblies.

- Developing and implementing quality control procedures and inspection checklists.

- Training and mentoring assembly operators on proper assembly techniques and quality control measures.

- Conducting regular quality audits and inspections to identify and address potential quality issues.

- Working closely with suppliers to ensure the quality of incoming materials and components.

2. Describe the different types of screw assembly machines you have experience with.

Manual Screw Assembly Machines

- Handheld screwdrivers for small-scale assembly tasks.

- Benchtop screwdrivers for medium-sized assemblies.

Semi-Automated Screw Assembly Machines

- Automatic screw feeders to dispense and orient screws.

- Automatic screwdrivers to drive screws into place.

Fully Automated Screw Assembly Machines

- Robotic systems that perform all assembly operations, including screw driving.

- Conveyorized systems that move assemblies through multiple workstations for screw driving.

3. How do you handle production delays and troubleshoot assembly issues?

When faced with production delays or assembly issues, I follow a systematic approach to identify and resolve the root cause:

- Investigate the issue thoroughly by gathering data, interviewing operators, and reviewing assembly logs.

- Identify potential sources of the problem, such as machine malfunction, operator error, or material defects.

- Develop and implement corrective actions to eliminate the issue and prevent recurrence.

- Monitor the situation closely to ensure the issue has been resolved and production has resumed smoothly.

4. How do you manage and motivate a team of screw assembly operators?

I believe in leading a team by empowering, motivating, and supporting my operators:

- Set clear expectations and goals for each operator and provide regular feedback on their performance.

- Create a positive and collaborative work environment where operators feel valued and respected.

- Provide opportunities for growth and development through training and skill enhancement programs.

- Recognize and reward operators for their contributions and achievements.

- Foster a sense of teamwork and encourage operators to share ideas and support each other.

5. What is your approach to reducing assembly costs and improving efficiency?

To reduce assembly costs and improve efficiency, I focus on the following strategies:

- Optimizing assembly processes by analyzing cycle times, identifying bottlenecks, and implementing lean manufacturing principles.

- Negotiating favorable pricing and terms with suppliers for materials and components.

- Investing in automation and technology to increase productivity and reduce labor costs.

- Training operators on proper assembly techniques to minimize rework and scrap.

- Implementing preventive maintenance programs to reduce downtime and ensure equipment reliability.

6. How do you stay updated on the latest trends and advancements in screw assembly technology?

I stay updated on the latest trends and advancements in screw assembly technology through various channels:

- Attending industry conferences and exhibitions.

- Reading technical journals and white papers.

- Networking with industry professionals and experts.

- Conducting research and exploring new technologies online.

- Participating in training and certification programs offered by equipment manufacturers.

7. Describe a particularly challenging screw assembly project you handled and how you overcame the challenges.

In my previous role, I was involved in a project to assemble a complex electronic device that required precise screw placement and high assembly quality. The challenges included:

- Limited workspace and access to the assembly area.

- Specialized screws with non-standard heads and tight tolerances.

- Strict quality requirements with zero tolerance for defects.

To overcome these challenges, I implemented the following measures:

- Designed and fabricated custom tools and fixtures to facilitate assembly in the confined space.

- Sourced and tested different screw types and suppliers to find the best combination of quality and cost.

- Developed and documented detailed assembly procedures and inspection criteria.

- Provided comprehensive training to operators and monitored their performance closely.

As a result of these efforts, we were able to successfully assemble the device, meet the stringent quality requirements, and deliver it on time.

8. How do you ensure compliance with safety regulations and quality standards in your work?

Ensuring compliance with safety regulations and quality standards is paramount in my work:

- Maintain a thorough understanding of all applicable safety regulations and quality standards.

- Develop and implement comprehensive safety and quality control procedures.

- Regularly train and educate operators on safety and quality protocols.

- Conduct regular safety and quality audits to identify and address any potential risks or non-conformances.

- Work closely with management to ensure compliance with company policies and external regulations.

9. How do you manage inventory and minimize waste in your screw assembly operations?

Effective inventory management and waste minimization are essential for optimizing screw assembly operations:

- Implement an inventory control system to track stock levels and reorder materials as needed.

- Optimize inventory levels to avoid overstocking and reduce storage costs.

- Establish clear procedures for receiving, storing, and issuing materials to prevent loss or damage.

- Identify and segregate scrap materials and implement recycling programs to minimize waste.

- Collaborate with suppliers to explore sustainable packaging options and reduce waste.

10. What are your strengths and weaknesses as a Screw Supervisor?

Strengths

- Proven ability to manage and optimize screw assembly processes.

- Expertise in screw assembly equipment, techniques, and quality control.

- Excellent leadership and communication skills, with a strong focus on teamwork and motivation.

- In-depth understanding of safety regulations and quality standards, and a commitment to compliance.

- Ability to analyze and solve problems, and implement effective solutions.

Weaknesses

- Limited experience in certain highly specialized screw assembly applications.

- A tendency to be detail-oriented, which can sometimes lead to spending excessive time on minor issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screw Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screw Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Screw Supervisor is responsible for all aspects of screw production within a manufacturing environment. They are responsible for managing a team of screw operators, ensuring that screws are produced to high quality standards within specified timeframes. Key job responsibilities include:

1. Production Management

Plan, schedule, and coordinate screw production activities to meet customer demand and ensure efficient operations.

- Develop and implement production plans to maximize output.

- Monitor production processes to identify and address bottlenecks.

- Ensure compliance with production standards and quality control procedures.

2. Team Management

Lead, motivate, and develop a team of screw operators to achieve production targets.

- Hire, train, and evaluate screw operators.

- Provide ongoing feedback and support to team members.

- Create a positive and productive work environment.

3. Quality Control

Conduct regular quality inspections to ensure that screws meet specifications.

- Establish and maintain quality control standards.

- Identify and correct quality defects.

- Provide feedback to operators on quality issues.

4. Equipment Maintenance

Ensure that screw machines and equipment are in good working condition.

- Identify and troubleshoot machine problems.

- Schedule and oversee maintenance activities.

- Maintain an inventory of spare parts.

Interview Tips

To ace an interview for a Screw Supervisor position, it is essential to prepare thoroughly. Here are some tips:

1. Research the Company and Position

Learn about the company’s history, products, and industry standing. Research the specific job description to understand the key job responsibilities.

- Example: “I’ve reviewed Acme Screw Company’s website and was impressed by your commitment to sustainable manufacturing.”

- Example: “Regarding the Screw Supervisor position, I noticed that you emphasize quality control. I’ve implemented several quality control initiatives in my previous role that resulted in significant defect reduction.”

2. Highlight Your Experience

Quantify your accomplishments and provide specific examples of your success in previous roles.

- Example: “In my previous role, I managed a team of 10 screw operators and consistently exceeded production targets by 15%.”

- Example: “I developed and implemented a new quality control system that reduced screw defects by 20%, saving the company thousands of dollars.”

3. Prepare Questions

Asking insightful questions shows that you are engaged and interested in the position. Prepare a few questions related to the company, industry, or job responsibilities.

- Example: “Can you tell me more about Acme Screw Company’s future growth plans?”

- Example: “What are the biggest challenges facing the screw industry right now?”

4. Practice Your Answers

Practice answering common interview questions out loud. This will help you feel more confident and articulate during the interview.

- Example: Practice answering questions about your leadership style, problem-solving abilities, and motivation for this position.

5. Dress Professionally

First impressions matter. Dress appropriately for the interview, typically in business attire.

- Example: Wear a suit, dress, or other professional attire.

6. Be Enthusiastic

Show the interviewer that you are excited about the opportunity to work for their company.

- Example: “I am very excited about the prospect of joining Acme Screw Company and contributing to your success.”

7. Follow Up

After the interview, send a thank-you note to the interviewer. This shows your appreciation for their time and consideration.

- Example: “Dear Mr./Ms. Interviewer, thank you for taking the time to interview me for the Screw Supervisor position. I am very interested in the opportunity and believe that my skills and experience would be a valuable asset to your team. I look forward to hearing from you soon.”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Screw Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Screw Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.