Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Screwdown Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

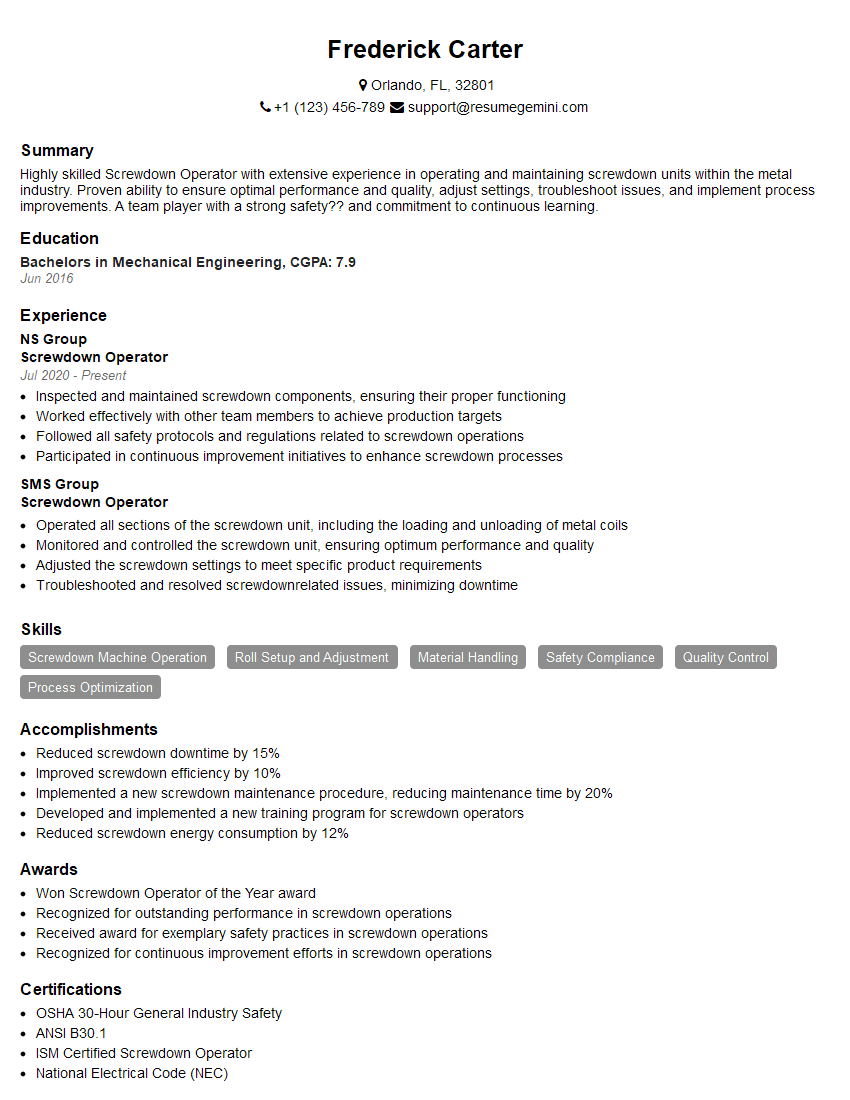

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screwdown Operator

1. Tell me about the types of screw machines you have worked on.

I have worked on a variety of screw machines including CNC screw machines, single-spindle screw machines, and multi-spindle screw machines. I am familiar with the different types of tooling and attachments used on these machines and can quickly set up and operate them.

2. What is your experience with screw thread inserts?

I have extensive experience with screw thread inserts. I am familiar with the different types of inserts and how to properly install and remove them. I can also troubleshoot problems that may occur with screw thread inserts.

3. How do you ensure that the screws you produce meet the required specifications?

I use a variety of techniques to ensure that the screws I produce meet the required specifications. These techniques include using precision measuring tools, checking the screws for defects, and following the quality control procedures that are in place at my workplace.

4. What is your experience with troubleshooting screw machines?

I have a lot of experience with troubleshooting screw machines. I am familiar with the different types of problems that can occur and can quickly identify the source of the problem. I can also make the necessary repairs and adjustments to get the machine up and running again.

5. What is your experience with preventive maintenance on screw machines?

I am familiar with the preventive maintenance procedures that are recommended for screw machines. I can perform these procedures on a regular basis to help prevent problems from occurring and to extend the life of the machine.

6. What is your experience with working as part of a team?

I have a lot of experience with working as part of a team. I am able to work independently and as part of a team to achieve the common goal. I am also able to communicate effectively with my team members and to share my knowledge and experience.

7. What is your experience with working under pressure?

I am able to work under pressure and to meet deadlines. I am also able to remain calm and focused when working under pressure. I am able to prioritize my work and to manage my time effectively.

8. What is your experience with working with customers?

I have a lot of experience with working with customers. I am able to communicate effectively with customers and to understand their needs. I am also able to resolve customer complaints and to build strong relationships with customers.

9. What is your experience with using computer-aided design (CAD) software?

I am familiar with the use of CAD software. I can use CAD software to create drawings and models of screws. I can also use CAD software to generate tool paths for screw machines.

10. What is your experience with using computer-aided manufacturing (CAM) software?

I am familiar with the use of CAM software. I can use CAM software to create tool paths for screw machines. I can also use CAM software to simulate the machining process and to optimize the tool path.

11. What is your experience with using quality control software?

I am familiar with the use of quality control software. I can use quality control software to collect and analyze data on the quality of screws. I can also use quality control software to generate reports on the quality of screws.

12. What is your experience with using statistical process control (SPC) techniques?

I am familiar with the use of SPC techniques. I can use SPC techniques to monitor and control the quality of screws. I can also use SPC techniques to identify trends and to improve the quality of screws.

13. What is your experience with using Six Sigma techniques?

I am familiar with the use of Six Sigma techniques. I can use Six Sigma techniques to improve the quality of screws. I can also use Six Sigma techniques to reduce waste and to increase efficiency.

14. What is your experience with using lean manufacturing techniques?

I am familiar with the use of lean manufacturing techniques. I can use lean manufacturing techniques to improve the quality of screws. I can also use lean manufacturing techniques to reduce waste and to increase efficiency.

15. What is your experience with using Total Productive Maintenance (TPM)?

I am familiar with the use of TPM. I can use TPM to improve the quality of screws. I can also use TPM to reduce waste and to increase efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screwdown Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screwdown Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Screwdown Operator is responsible for the operation and maintenance of screwdown equipment, ensuring the smooth and efficient production of oil and gas.

1. Screwdown Control

Continuously monitor and control the movement of the screwdown system, adjusting as needed to maintain the correct load on the drill bit.

- Set and maintain drilling parameters

- Monitor the performance of the screwdown equipment

2. Equipment Maintenance

Maintain and perform necessary repairs on screwdown equipment, including hydraulic systems, mechanical components, and sensors.

- Lubricate and clean screwdown components

- Replace worn or damaged parts

3. Wellbore Monitoring

Monitor wellbore conditions using pressure and temperature gauges, ensuring optimal drilling conditions and safety.

- Observe and interpret drilling data

- Communicate wellbore conditions to the drilling team

4. Safety Compliance

Adhere to all safety regulations and procedures while operating screwdown equipment, including proper use of personal protective equipment and emergency response protocols.

- Follow drilling company safety guidelines

- Report any safety concerns or incidents immediately

Interview Tips

A well-prepared candidate can make a strong impression during an interview for a Screwdown Operator position. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the drilling company and the specific Screwdown Operator position. This will demonstrate your interest in the role and the company, and it will help you to ask informed questions during the interview.

- Visit the company’s website

- Read industry publications

- Network with professionals in the field

2. Highlight Your Skills and Experience

During the interview, be prepared to discuss your relevant skills and experience as they relate to the Screwdown Operator role. Focus on your ability to operate and maintain screwdown equipment, as well as your knowledge of wellbore monitoring and safety procedures.

- Provide specific examples of your experience

- Quantify your accomplishments whenever possible

- Be confident in your abilities

3. Demonstrate Your Safety Knowledge

Safety is paramount in the oil and gas industry, so it is essential to demonstrate your knowledge of safety regulations and procedures. Discuss your experience with following safety protocols, and be prepared to answer questions about how you would handle different safety situations.

- Be familiar with OSHA regulations

- Describe your experience with safety drills

- Explain how you would respond to a safety emergency

4. Ask Thoughtful Questions

At the end of the interview, you will likely have the opportunity to ask questions. This is your chance to learn more about the company and the position, and to show the interviewer that you are engaged and interested in the role.

- Ask about the company’s safety culture

- Inquire about opportunities for professional development

- Ask about the company’s environmental sustainability practices

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Screwdown Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!