Are you gearing up for an interview for a Scrubber Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Scrubber Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

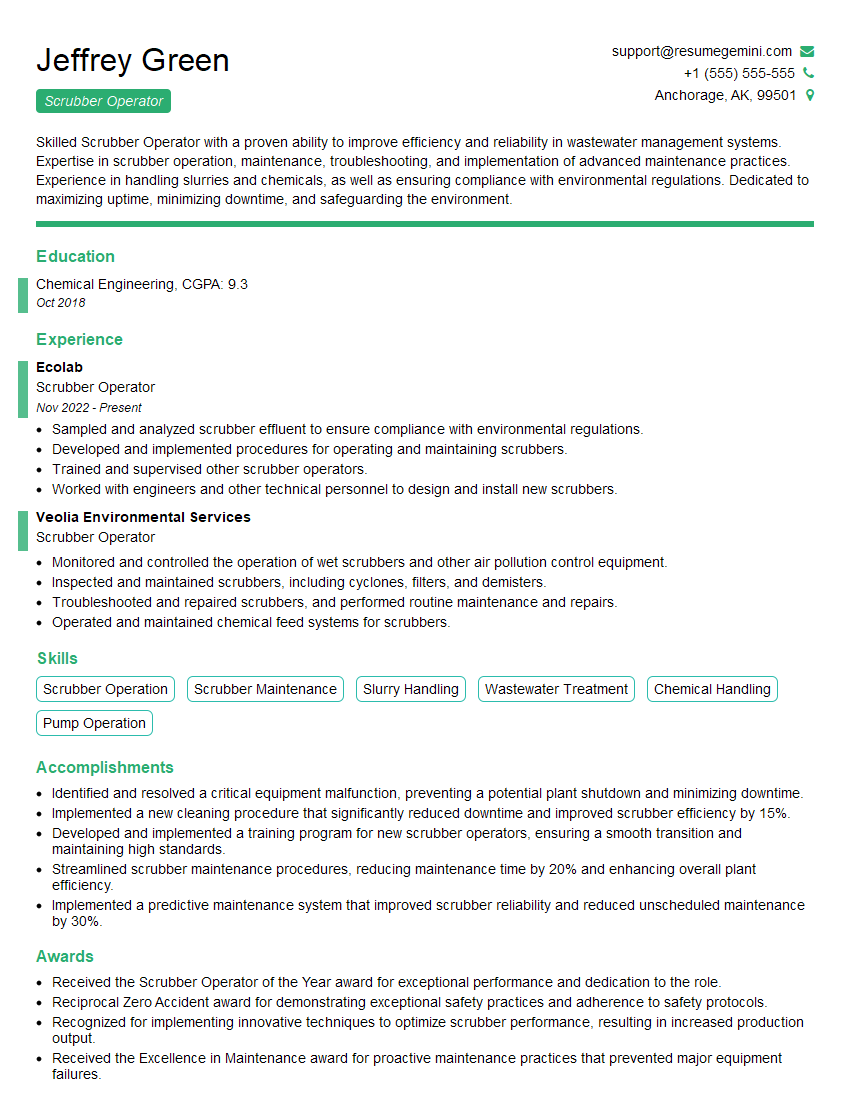

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scrubber Operator

1. Explain the different types of scrubbers used in industrial processes, and their respective advantages and disadvantages?

Scrubbers are used to remove pollutants from gases or liquids. The most common types of scrubbers used in industrial processes are:

- Wet scrubbers: These scrubbers use water or another liquid to remove pollutants from gases. Wet scrubbers are efficient at removing both particulate and gaseous pollutants, but they can be expensive to operate and maintain.

- Dry scrubbers: These scrubbers use a dry sorbent, such as lime or activated carbon, to remove pollutants from gases. Dry scrubbers are less efficient than wet scrubbers at removing gaseous pollutants, but they are less expensive to operate and maintain.

- Venturi scrubbers: These scrubbers use a high-velocity gas stream to remove pollutants from gases. Venturi scrubbers are efficient at removing both particulate and gaseous pollutants, but they can be noisy and require a lot of energy to operate.

2. How do you determine the efficiency of a scrubber?

Pressure Drop

- The pressure drop across the scrubber is a measure of the energy required to operate the scrubber.

- A higher pressure drop means that the scrubber is more efficient at removing pollutants, but it also means that the scrubber will require more energy to operate.

Collection Efficiency

- The collection efficiency of a scrubber is a measure of the percentage of pollutants that are removed from the gas stream.

- The collection efficiency of a scrubber is affected by a number of factors, including the type of scrubber, the operating conditions, and the characteristics of the pollutants.

3. What are the common operating problems associated with scrubbers, and how can they be resolved?

Some of the common operating problems associated with scrubbers include:

- Clogging: This can be caused by a build-up of solids in the scrubber. Clogging can be prevented by using a pre-filter to remove solids from the gas stream before it enters the scrubber.

- Corrosion: This can be caused by the presence of corrosive gases or liquids in the gas stream. Corrosion can be prevented by using corrosion-resistant materials in the construction of the scrubber.

- Scaling: This can be caused by the build-up of minerals in the scrubber. Scaling can be prevented by using a water treatment system to remove minerals from the water used in the scrubber.

4. How do you maintain a scrubber to ensure its optimal performance?

To ensure optimal performance, scrubbers should be regularly inspected and maintained. Some of the maintenance tasks that should be performed on a regular basis include:

- Checking the pressure drop across the scrubber. If the pressure drop is too high, the scrubber may need to be cleaned or repaired.

- Checking the collection efficiency of the scrubber. If the collection efficiency is too low, the scrubber may need to be adjusted or repaired.

- Inspecting the scrubber for signs of wear or damage. Any worn or damaged parts should be repaired or replaced immediately.

5. What safety precautions should be taken when operating a scrubber?

When operating a scrubber, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and a respirator.

- Be aware of the potential hazards associated with the scrubber. These hazards include exposure to corrosive chemicals, high-pressure gases, and electrical hazards.

- Follow all operating procedures carefully. Do not attempt to operate the scrubber unless you have been properly trained.

6. What are the environmental regulations that apply to scrubber operation?

The environmental regulations that apply to scrubber operation vary depending on the jurisdiction. In general, scrubbers must be operated in a manner that minimizes the emission of pollutants into the environment.

7. What are the emerging trends in scrubber technology?

The emerging trends in scrubber technology include:

- The development of more efficient scrubbers. This includes the development of scrubbers that can remove a wider range of pollutants and that operate at lower energy costs.

- The development of more compact scrubbers. This is important for applications where space is limited.

- The development of more automated scrubbers. This can reduce the operating costs of scrubbers.

8. What are the key factors to consider when selecting a scrubber for a particular application?

The key factors to consider when selecting a scrubber for a particular application include:

- The type of pollutants that need to be removed.

- The flow rate of the gas stream.

- The pressure drop that is acceptable.

- The collection efficiency that is required.

- The operating costs.

9. Can you describe a situation where you successfully troubleshooted a problem with a scrubber?

Yes, I have successfully troubleshooted a problem with a scrubber on several occasions. One example that comes to mind is a time when the scrubber was not removing the desired amount of pollutants from the gas stream. I was able to troubleshoot the problem and determine that the scrubber was not operating at the correct pressure. I adjusted the pressure and the scrubber began operating properly.

10. What are your strengths and weaknesses as a Scrubber Operator?

Strengths

- I have a strong understanding of the principles of scrubber operation.

- I am experienced in operating and maintaining scrubbers.

- I am a quick learner and I am always willing to take on new challenges.

Weaknesses

- I am relatively new to the field of scrubber operation.

- I do not have any experience operating scrubbers in a large-scale industrial setting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scrubber Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scrubber Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Scrubber Operator is accountable for ensuring the effective and efficient operation of scrubbers in industrial or commercial settings. These systems are crucial for controlling air pollution and maintaining a clean and safe work environment.

1. Operate and Monitor Scrubber Systems

Skilled operation of scrubber systems is crucial to ensure optimal performance and pollution control. This involves:

- Monitoring system parameters such as pH levels, pressure, and flow rates

- Adjusting process variables to optimize scrubber efficiency

- Troubleshooting and resolving operational issues promptly

2. Inspect and Maintain Scrubber Equipment

Regular inspection and maintenance are essential to keep scrubbers functioning properly. This includes:

- Inspecting scrubbers for signs of wear, corrosion, or damage

- Performing routine maintenance tasks such as cleaning, lubrication, and replacing worn components

- Coordinating with maintenance teams for major repairs or upgrades

3. Monitor Environmental Compliance

Scrubber Operators play a critical role in ensuring compliance with environmental regulations. This involves:

- Monitoring emissions to ensure compliance with regulatory standards

- Maintaining records and documentation related to scrubber operations and emissions

- Reporting any deviations from environmental regulations promptly

4. Ensure Safety and Efficiency

Scrubber Operators are responsible for maintaining a safe and efficient work environment. This includes:

- Following established safety protocols and procedures

- Identifying and mitigating potential hazards associated with scrubber operations

- Promoting a culture of safety and continuous improvement within the work team

Interview Tips

To ace the interview for a Scrubber Operator position, it’s important to:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, industry trends, and environmental regulations. This shows the interviewer that you are prepared and interested in the role.

2. Highlight Relevant Experience and Skills

Emphasize your experience and skills in operating and maintaining scrubber systems. Quantify your accomplishments using specific examples and metrics whenever possible.

3. Demonstrate Understanding of Environmental Compliance

Discuss your knowledge of environmental regulations and your experience in ensuring compliance. Explain how you would approach monitoring emissions and reporting any deviations.

4. Showcase Safety and Problem-Solving Abilities

Highlight your commitment to safety and your ability to troubleshoot and resolve problems. Describe specific situations where you identified and addressed operational issues effectively.

Next Step:

Now that you’re armed with the knowledge of Scrubber Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Scrubber Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini