Are you gearing up for a career in Scutcher Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Scutcher Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

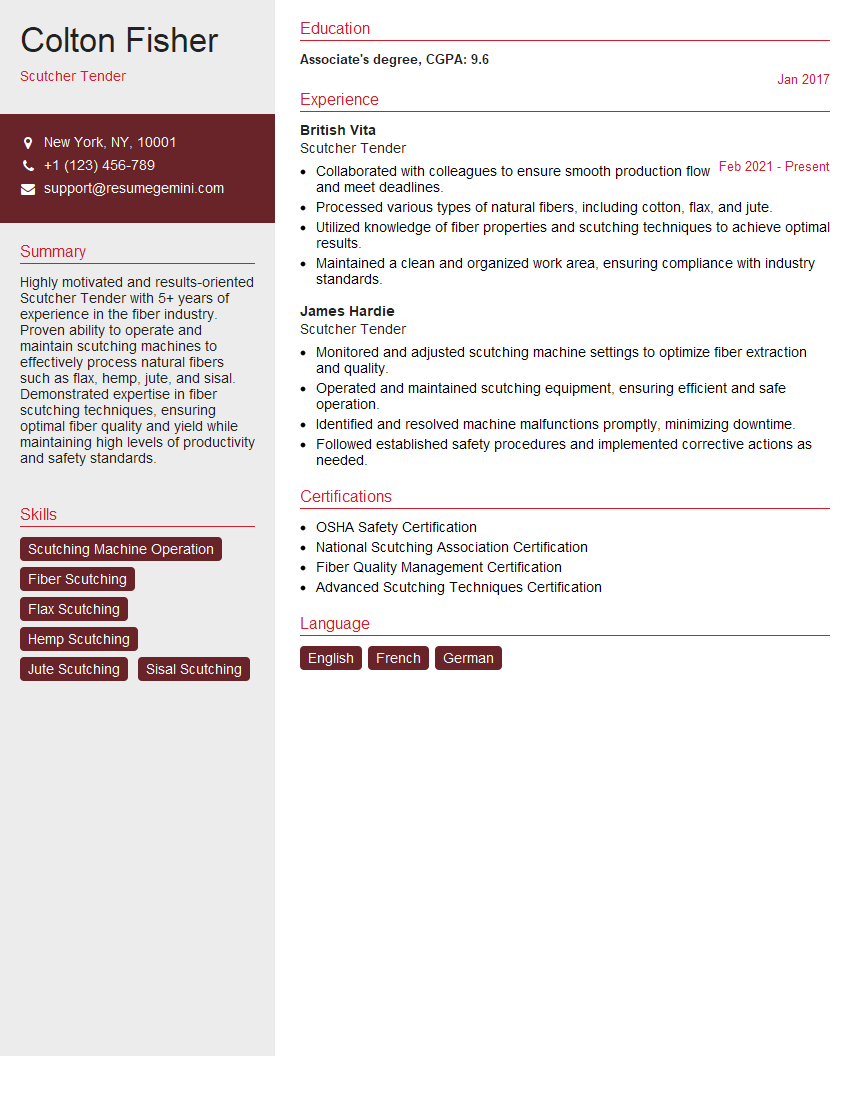

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scutcher Tender

1. Explain the process of scutching in detail?

Scutching is the process of separating the fibers of the jute plant from the woody core. It is a complex process that involves several steps:

- Retting: The jute plants are first soaked in water for several days or weeks. This softens the fibers and makes them easier to separate from the core.

- Breaking: The retted plants are then broken into small pieces using a machine called a breaker.

- Scutching: The broken pieces are then beaten with a wooden mallet or a scutching machine. This separates the fibers from the core.

- Washing: The scutched fibers are then washed in water to remove any remaining impurities.

- Drying: The washed fibers are finally dried in the sun or in a dryer.

2. What are the different types of scutching machines?

Manually operated scutching machines

- Hand scutching

- Paddle scutching

Power operated scutching machines

- Beater scutchers

- Roller scutchers

- Disc scutchers

3. What are the factors that affect the quality of scutched fibers?

The quality of scutched fibers is affected by several factors, including:

- The quality of the jute plants. Plants that are healthy and have a high fiber content will produce higher quality fibers.

- The retting process. The length of time that the plants are retted will affect the quality of the fibers. Over-retting can damage the fibers, while under-retting can make them difficult to separate from the core.

- The scutching process. The type of scutching machine used and the skill of the operator can affect the quality of the fibers. Over-scutching can damage the fibers, while under-scutching can leave impurities in the fibers.

- The drying process. The fibers must be dried properly to prevent them from becoming moldy or mildewed.

4. What are the common problems that can occur during scutching?

Some of the common problems that can occur during scutching include:

- Fiber breakage. This can occur if the fibers are over-retted or if the scutching machine is not properly adjusted.

- Impurities in the fibers. This can occur if the fibers are not properly cleaned during the washing process.

- Mold or mildew. This can occur if the fibers are not properly dried.

5. What are the safety precautions that should be taken when operating a scutching machine?

The following safety precautions should be taken when operating a scutching machine:

- Wear protective clothing, including gloves, goggles, and a dust mask.

- Make sure that the machine is properly guarded.

- Do not operate the machine if you are not trained.

- Keep the work area clean and free of debris.

- Follow all manufacturer’s instructions.

6. What are the maintenance procedures that should be performed on a scutching machine?

The following maintenance procedures should be performed on a scutching machine on a regular basis:

- Inspect the machine for any damage.

- Lubricate the moving parts.

- Clean the machine thoroughly.

- Adjust the machine as necessary.

- Follow all manufacturer’s instructions.

7. What are the troubleshooting procedures for a scutching machine?

The following troubleshooting procedures can be performed if a scutching machine is not working properly:

- Check the power supply.

- Check the fuses.

- Check the belts.

- Check the bearings.

- Check the scutching blades.

- Follow all manufacturer’s instructions.

8. What are the quality standards for scutched fibers?

The quality of scutched fibers is determined by several factors, including:

- The fiber length.

- The fiber strength.

- The fiber color.

- The fiber moisture content.

- The fiber impurities.

9. What are the different uses of scutched fibers?

Scutched fibers are used in a variety of applications, including:

- Textiles. Scutched fibers are used to make a variety of textiles, including jute, burlap, and hessian.

- Paper. Scutched fibers are used to make a variety of papers, including newsprint, cardboard, and paper bags.

- Other uses. Scutched fibers are also used in a variety of other applications, including ropes, twine, and insulation.

10. How does scutching impact the environment?

Scutching can have a negative impact on the environment if the wastewater from the process is not properly treated. The wastewater can contain high levels of organic matter, which can pollute rivers and streams. In addition, the retting process can produce methane, which is a greenhouse gas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scutcher Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scutcher Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scutcher Tenders are responsible for operating and maintaining scutching machines, which are used to separate fibers from other materials in a variety of industrial processes, such as textile manufacturing and paper production.

1. Operating Scutching Machines

Scutcher Tenders must be able to set up and operate scutching machines according to manufacturer’s instructions and established operating procedures.

- Loading and unloading materials into and from scutching machines

- Monitoring scutching machines for proper operation and making adjustments as needed

2. Maintaining Scutching Machines

Scutcher Tenders must be able to perform basic maintenance on scutching machines, including lubrication, cleaning, and minor repairs.

- Identifying and replacing worn or damaged parts

- Keeping records of maintenance performed

3. Inspecting Materials

Scutcher Tenders must be able to inspect materials before and after scutching to ensure that the desired results are achieved.

- Identifying and removing foreign objects from materials

- Checking materials for defects or damage

4. Safety

Scutcher Tenders must be able to follow all safety procedures and wear appropriate personal protective equipment (PPE) when operating scutching machines.

- Reporting any unsafe conditions or practices

- Using lockout/tagout procedures when performing maintenance on scutching machines

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success.

1. Research the Company and Position

Before you go to an interview, it’s important to do your research on the company and the position you’re applying for. This will help you understand the company’s culture and values, and what the hiring manager is looking for in a candidate.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read the job description carefully and identify the key requirements.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Prepare a brief, 30-second elevator pitch that summarizes your skills and experience.

- Brainstorm stories and examples that highlight your relevant skills and accomplishments.

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re organized and respectful of their time.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Arrive at the interview location at least 15 minutes early.

4. Be Yourself and Be Confident

It’s important to be yourself and be confident during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and upfront about your skills and experience.

- Maintain eye contact and speak clearly and confidently.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Scutcher Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.