Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Seal Extrusion Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

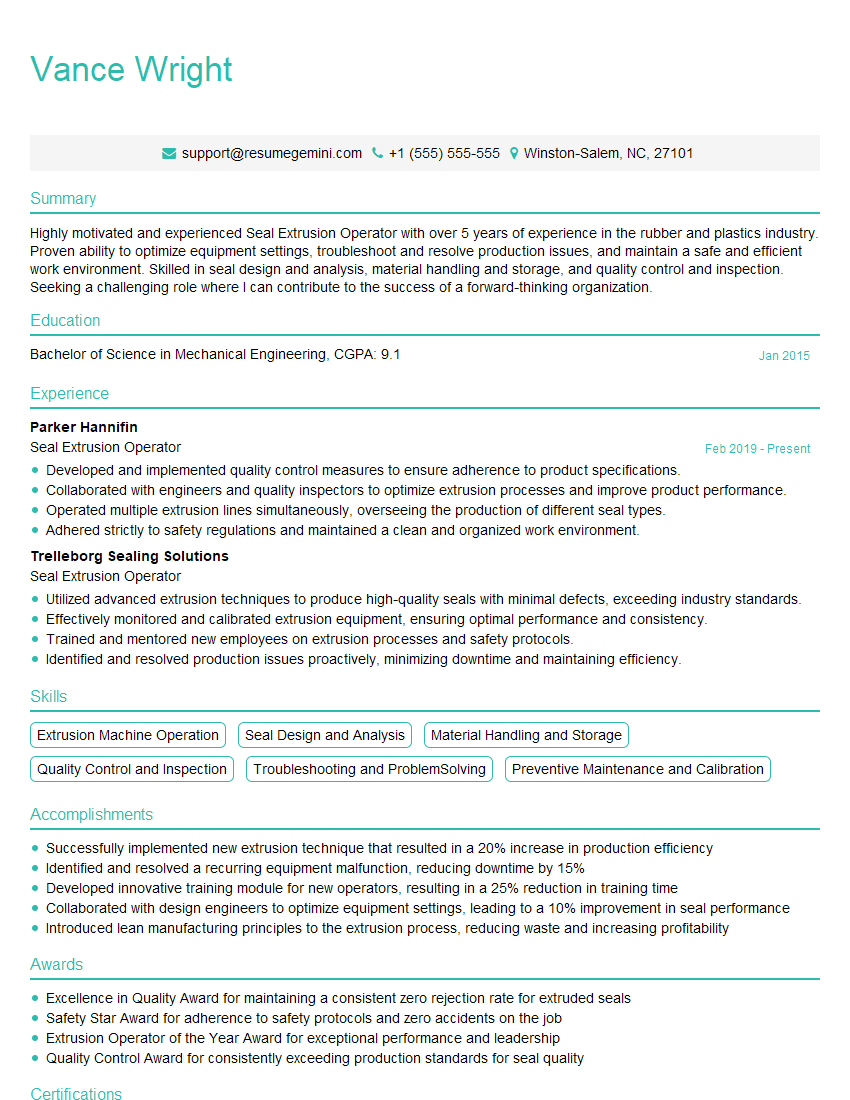

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seal Extrusion Operator

1. What is the purpose of a mixing chamber in a seal extrusion process?

The mixing chamber in a seal extrusion process serves multiple purposes:

- Mixing of Ingredients: It combines the elastomeric compound, fillers, and other additives to create a homogeneous mixture.

- Devolatilization: It removes trapped air and gases from the mixture to ensure product integrity and prevent defects.

- Temperature Control: It maintains the desired temperature of the mixture to facilitate proper curing and extrusion.

2. Describe the different types of seal cross-sections and their applications.

O-Rings:

- Circular cross-section

- Used for static and dynamic sealing in various applications, such as hydraulic and pneumatic systems.

Quad-Rings:

- Four-lobed cross-section

- Provides improved sealing performance and can accommodate higher pressures than O-Rings.

U-Cups:

- U-shaped cross-section

- Used in piston and cylinder applications, offering high sealing efficiency and low friction.

3. What are the key parameters to monitor during seal extrusion?

- Extrusion Pressure: Ensures proper material flow and adhesion.

- Temperature Profile: Maintains the correct temperatures for curing and material properties.

- Material Feed Rate: Controls the amount of material entering the extruder.

- Product Dimensions: Verifies the accuracy and consistency of the extruded seals.

4. Explain the role of curing in seal extrusion and its impact on product quality.

- Chemical Reaction: Curing triggers a chemical reaction that transforms the elastomeric compound into a solid form.

- Material Strength: Proper curing improves the strength, resilience, and sealing performance of the seals.

- Product Integrity: Adequate curing ensures the stability and longevity of the seals over time.

5. How do you maintain a clean and efficient work area in a seal extrusion facility?

- Regular Cleaning: Frequent cleaning of equipment, surfaces, and tools removes debris and contaminants.

- Material Handling: Proper handling of raw materials and finished products prevents contamination and damage.

- Waste Management: Effective waste disposal systems minimize clutter and maintain a safe work environment.

- Preventive Maintenance: Regular maintenance checks and repairs reduce downtime and ensure equipment cleanliness.

6. Describe the safety precautions you observe when working with seal extrusion machinery.

- PPE: Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Guarding: Ensuring that machine guards are in place and properly maintained to prevent injuries.

- Lockout/Tagout: Following procedures for lockout/tagout during maintenance or repairs to prevent accidental startups.

- Hazard Identification: Recognizing potential hazards and taking appropriate precautions, such as avoiding hot surfaces or moving machinery.

7. What troubleshooting techniques do you use when seal extrusion defects occur?

- Identify Symptoms: Determine the specific defects, such as surface imperfections, dimensional inaccuracies, or poor sealing performance.

- Root Cause Analysis: Investigate potential causes, such as material contamination, incorrect processing parameters, or equipment malfunctions.

- Corrective Actions: Implement corrective measures, such as adjusting settings, cleaning components, or replacing defective parts.

- Process Improvement: Analyze the results and make adjustments to prevent similar defects from recurring.

8. Explain the importance of quality control in seal extrusion.

- Product Consistency: Ensures that seals meet customer specifications and perform as intended.

- Customer Satisfaction: High-quality seals enhance customer satisfaction and reduce the risk of product returns or complaints.

- Regulatory Compliance: Adhering to industry standards and regulations for seal quality and safety.

- Cost Savings: Minimizes waste and rework, reducing overall production costs.

9. Describe the use of automated systems in seal extrusion.

- Process Control: Automated systems monitor and adjust extrusion parameters, ensuring optimal conditions.

- Quality Inspection: Vision systems and other automated inspection techniques check seal dimensions and surface quality.

- Material Handling: Robots and conveyors automate material handling, reducing manual labor and improving efficiency.

- Data Collection: Automated systems collect and analyze data, providing insights for process optimization.

10. What are the current industry trends in seal extrusion technology?

- Advanced Materials: Development of high-performance elastomers with enhanced properties for demanding applications.

- Additive Manufacturing: Use of 3D printing for prototyping and production of customized seals.

- Sustainability: Focus on using environmentally friendly materials and reducing waste in extrusion processes.

- Industry 4.0: Integration of smart technologies and automation for improved efficiency and predictive maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seal Extrusion Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seal Extrusion Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Seal Extrusion Operators are responsible for the production of rubber or plastic seals and gaskets, which are primarily used in the automotive and construction sectors. To achieve this, they operate extrusion machines to convert raw materials into the desired shape and size. Here are the key responsibilities of a Seal Extrusion Operator:

1. Machine Operation and Monitoring

The operator is accountable for the safe and efficient operation of the extrusion machine. They monitor the machine’s settings, including temperature, pressure, and speed, to ensure the production of high-quality seals.

2. Material Preparation

They prepare and mix raw materials such as rubber or plastic compounds and other additives to obtain the desired properties of the final product. Ensuring the proper mixing and preparation of materials is crucial for the quality of the seals.

3. Quality Control

The operator performs regular quality checks on the extruded seals to ensure they meet specifications and industry standards. They use tools and techniques like dimensional measurements and visual inspections to identify any defects or nonconformities.

4. Maintenance and Troubleshooting

To maintain optimal production, the operator conducts preventive maintenance tasks like cleaning and lubricating the extrusion machine. Additionally, they troubleshoot and resolve any issues or malfunctions that may arise during the extrusion process, ensuring minimal downtime.

5. Documentation and Reporting

Operators maintain accurate records of production data, quality control results, and any issues encountered during the extrusion process. They also provide regular reports to supervisors and quality control personnel to ensure transparency and process improvement.

Interview Tips

To prepare for an interview for a Seal Extrusion Operator role, consider the following tips:

1. Research the Company

Learn about the company’s history, products, and industry reputation. This demonstrates your interest and enthusiasm for the organization and its mission.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience operating extrusion machines, knowledge of materials and quality control procedures, and problem-solving abilities. Use the STAR (Situation, Task, Action, Result) method to structure your responses and provide specific examples.

3. Highlight Your Technical Skills

Emphasize your technical skills related to extrusion machines, such as understanding of process parameters, ability to adjust machine settings, and familiarity with maintenance procedures.

4. Demonstrate Problem-Solving Abilities

Share examples of how you have successfully identified and resolved issues or challenges in previous roles. Explain the steps you took and the results you achieved.

5. Ask Thoughtful Questions

At the end of the interview, ask insightful questions that demonstrate your engagement and interest in the role and the company. This could include questions about the company’s growth plans or the specific challenges or opportunities associated with the position.

6. Be Enthusiastic and Professional

Showcase your enthusiasm for the role of a Seal Extrusion Operator and the opportunity to contribute to the company’s success. Maintain a professional demeanor and dress appropriately for the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Seal Extrusion Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.