Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sealing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

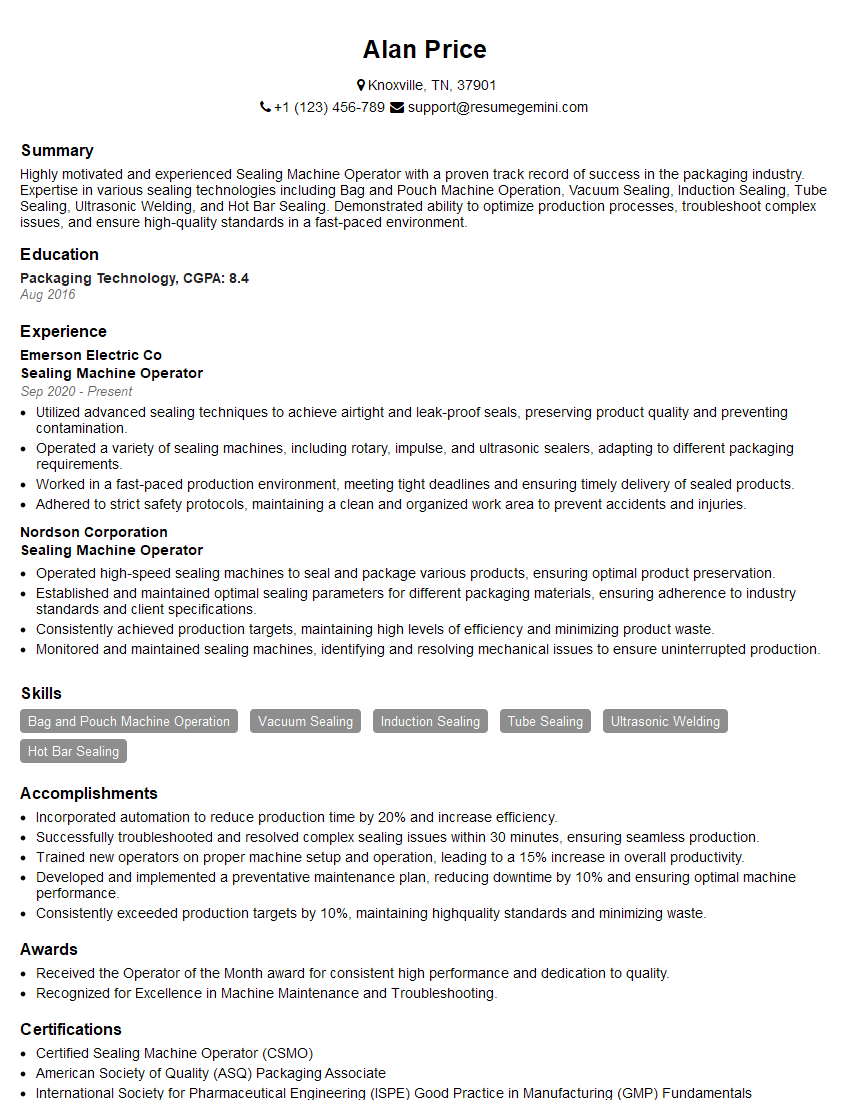

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sealing Machine Operator

1. What are the different types of sealing machines and their applications?

There are various types of sealing machines, each designed for specific applications. Some common types include:

- Impulse Sealers: Used for sealing thin and flexible materials like plastic bags and films. They apply heat for a short duration to create a bond.

- Heat Sealers: Similar to impulse sealers, but use continuous heat to seal thicker materials like coated papers, foils, and some plastics.

- Band Sealers: Form continuous seals around large bags, sacks, and pouches using a heated band.

- Vacuum Sealers: Create airtight seals by removing air from packages before sealing, preserving contents for extended periods.

- Ultrasonic Sealers: Utilize ultrasonic waves to create friction and heat, forming strong seals on materials like plastics, foils, and non-wovens.

2. How do you maintain and troubleshoot a sealing machine?

Preventive Maintenance:

- Regular cleaning to remove debris and ensure smooth operation.

- Lubrication of moving parts to reduce friction and wear.

Troubleshooting:

- Check power supply and ensure the machine is properly plugged in.

- Inspect heating elements for damage or wear, replacing if necessary.

- Examine sensors and switches for proper function and make necessary adjustments.

- Calibrate the machine regularly to ensure accurate seal parameters.

3. How do you select the appropriate sealing method and parameters for different materials?

Selecting the right method and parameters depends on the material properties:

- Material Thickness: Thicker materials require higher heat and pressure.

- Material Type: Different materials have varying melting points and adhesion properties.

Factors to consider when adjusting parameters:

- Temperature: Adjust heat based on material melting point.

- Dwell Time: Duration of heat application for proper bonding.

- Pressure: Apply sufficient pressure to create a strong seal.

4. What quality control measures do you implement to ensure the integrity of sealed packages?

- Visual Inspection: Examine seals for any visible defects, wrinkles, or gaps.

- Tensile Strength Testing: Measure the force required to break the seal, ensuring it meets specifications.

- Peel Strength Testing: Test the adhesion strength of the seal by peeling it apart.

- Leakage Testing: Use pressure or vacuum to check for any leaks in the seal.

- Record Keeping: Document test results to track quality and identify potential issues.

5. How do you handle and store different types of sealing materials?

- Plastic Films: Store in a cool, dry place away from direct sunlight and moisture.

- Foils: Keep in a moisture-controlled environment to prevent oxidation.

- Gaskets: Store in a clean, dry location to maintain their sealing properties.

- Adhesives: Follow manufacturer’s instructions for storage and handling to ensure optimal performance.

6. What safety precautions do you take when operating a sealing machine?

- Wear appropriate PPE: Gloves, safety glasses, and ear protection.

- Ensure proper machine setup: Check connections, guards, and emergency stops.

- Handle materials safely: Avoid sharp edges and hot surfaces.

- Be aware of moving parts: Keep hands clear of danger zones.

- Follow lockout/tagout procedures: De-energize machines before maintenance or repairs.

7. How do you minimize material waste and optimize sealing efficiency?

- Proper Material Selection: Choose the right materials for the application to minimize rejects.

- Precise Parameter Adjustment: Calibrate the machine to seal materials effectively without over-sealing.

- Regular Maintenance: Keep the machine in good working order to avoid downtime and material waste.

- Optimized Seal Design: Design seals to minimize material usage while ensuring product integrity.

- Batch Processing: Seal multiple packages together to reduce material consumption per unit.

8. What is your experience with sealing food products?

In my previous role at [Previous Company], I was responsible for operating and maintaining sealing machines used for packaging various food products, including:

- Fresh produce (fruits and vegetables)

- Dairy products (milk, cheese, yogurt)

- Meat and poultry products

I ensured proper seal integrity to maintain food quality and prevent contamination.

9. Can you describe a challenging sealing project you encountered and how you resolved it?

During the packaging of a new product, we faced challenges in achieving a leak-proof seal due to the material’s low melting point. After consulting with the material supplier and experimenting with different sealing parameters, we adjusted the temperature, dwell time, and pressure to find the optimal settings. This resulted in a strong and reliable seal, ensuring product protection and shelf life.

10. How do you stay updated with advancements in sealing technology?

- Attend industry conferences and exhibitions: Network with experts and learn about new products and techniques.

- Read trade publications and technical articles: Stay informed about the latest developments in the field.

- Participate in online forums and discussions: Engage with peers and share knowledge about sealing best practices.

- Collaborate with equipment manufacturers: Seek technical advice and support from industry experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sealing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sealing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sealing Machine Operators are responsible for operating and maintaining sealing machines that package a variety of products. Their primary duties include:

1. Operating Sealing Machines

Loading products into the sealing machine, ensuring proper alignment and placement.

- Adjusting machine settings and parameters, such as temperature, speed, and pressure, to optimize sealing processes.

- Monitoring the sealing process to ensure the quality and integrity of the seals.

2. Maintaining Sealing Machines

Performing routine maintenance tasks, such as cleaning, lubricating, and inspecting machines.

- Troubleshooting and resolving minor mechanical or electrical issues.

- Reporting any major mechanical or electrical issues to the supervisor or maintenance personnel.

3. Ensuring Quality and Safety

Inspecting sealed products to ensure they meet quality standards.

- Following established safety protocols and procedures to minimize risks and accidents.

- Maintaining a clean and organized work area.

4. Other Responsibilities

Assisting with other production tasks, as needed.

- Working effectively as part of a production team.

- Maintaining a positive and professional attitude.

Interview Tips

Preparing for an interview can significantly improve your chances of success. Here are some key tips to help you ace your interview for a Sealing Machine Operator position:

1. Research the Position and Company

Familiarize yourself with the specific job requirements and the company’s culture.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Practice Your Answers

Prepare answers to common interview questions, such as:

- Tell me about your experience operating sealing machines.

- How do you ensure the quality and integrity of seals?

- What is your experience with troubleshooting and resolving machine issues?

3. Highlight Relevant Experience and Skills

Emphasize your experience and skills that are relevant to the job. Use specific examples to demonstrate your abilities.

- Quantify your accomplishments whenever possible. For example, if you have experience increasing production efficiency, state the percentage increase.

- Use action verbs to describe your responsibilities and accomplishments.

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview shows that you are engaged and interested in the position.

- Prepare questions about the company’s products, processes, and future plans.

- Ask about the company’s training programs and opportunities for advancement.

5. Be Enthusiastic and Professional

Maintain a positive and professional demeanor throughout the interview.

- Dress appropriately and arrive on time for your interview.

- Make eye contact, smile, and speak clearly.

Next Step:

Now that you’re armed with the knowledge of Sealing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sealing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini