Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Seals Engraver position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

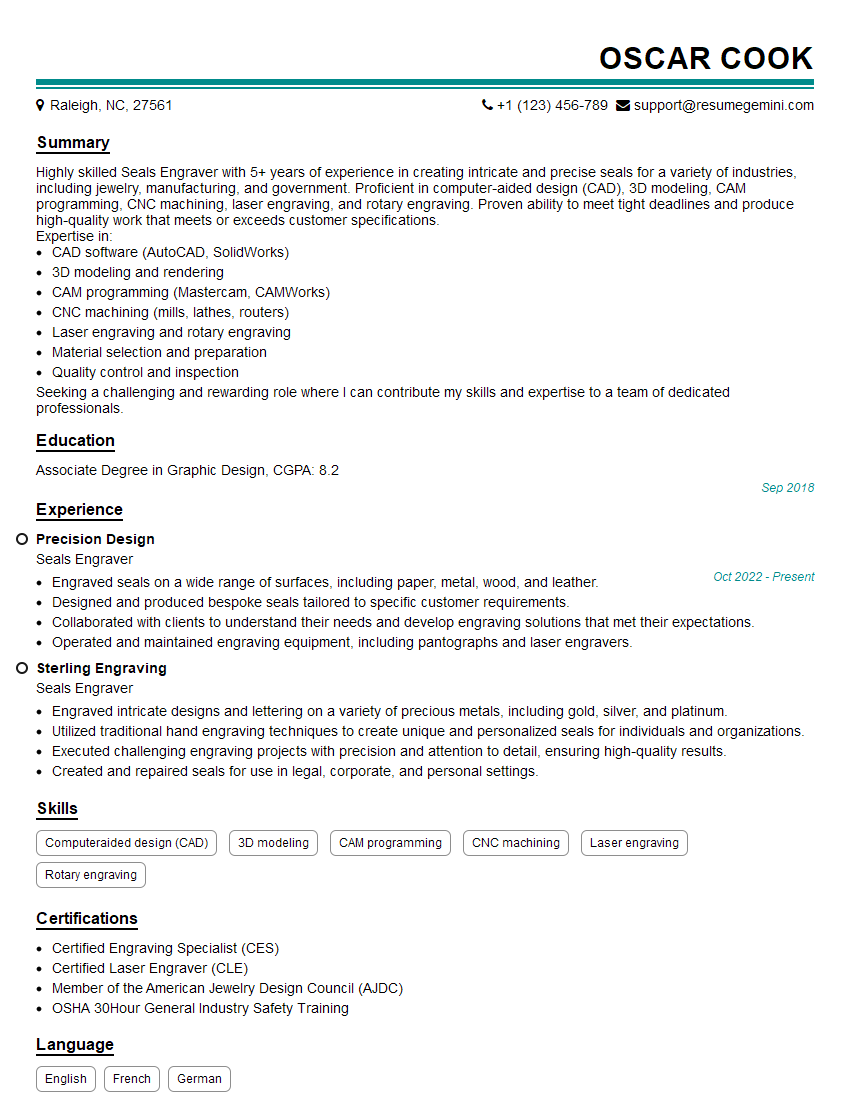

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seals Engraver

1. What techniques do you use to carve seals?

- The three main techniques used for carving seals are: relief carving, intaglio carving, and cameo carving.

- Relief carving is the process of carving a raised design on the surface of a stone, while intaglio carving is the process of carving a recessed design into the surface of a stone.

- Cameo carving is a combination of relief and intaglio carving, in which a raised design is carved on a background of a different color.

2. What are the different types of stones that can be used for carving seals?

Hardness of Stones

- The hardness of a stone is measured on the Mohs scale, which ranges from 1 to 10, with 1 being the softest and 10 being the hardest.

- Stones that are too soft will not hold a sharp edge, while stones that are too hard will be difficult to carve.

Types of Stones

- The most commonly used stones for carving seals are: jade, agate, carnelian, and bloodstone.

- Jade is a very hard stone (Mohs hardness 6.5-7), which makes it ideal for carving fine details.

- Agate is a banded gemstone that comes in a variety of colors, and it is also very hard (Mohs hardness 6.5-7).

- Carnelian is a red gemstone that is slightly softer than agate (Mohs hardness 6-7).

- Bloodstone is a green gemstone with red spots, and it is also slightly softer than agate (Mohs hardness 6-7).

3. How do you choose the right stone for a particular design?

- The type of stone that I choose for a particular design depends on a number of factors, including the hardness of the stone, the color of the stone, and the size of the design.

- For example, if I want to carve a fine, detailed design, I will choose a hard stone, such as jade or agate.

- If I want to carve a large design, I will choose a softer stone, such as carnelian or bloodstone.

- I will also consider the color of the stone when choosing a design. For example, if I want to carve a design with a lot of red, I will choose a stone, such as carnelian or bloodstone.

4. What tools do you use for carving seals?

- The basic tools that I use for carving seals are: a hammer, a chisel, and a graver.

- I also use a variety of other tools, such as files, sandpaper, and polishing wheels.

- The type of tools that I use depends on the hardness of the stone and the size of the design.

5. How do you maintain your tools?

- I maintain my tools by sharpening them regularly and by keeping them clean and free of rust.

- I also store my tools in a dry place to prevent them from rusting.

6. What are the different types of designs that can be carved on seals?

- There are many different types of designs that can be carved on seals, including: letters, numbers, symbols, and images.

- The type of design that I carve on a seal depends on the customer’s request.

7. How do you create a design for a seal?

- I create a design for a seal by first sketching out the design on paper.

- Once I am satisfied with the sketch, I transfer it to the stone.

- I then use a variety of carving tools to carve the design into the stone.

8. How do you ensure that the design is accurate and precise?

- I ensure that the design is accurate and precise by using a variety of measuring tools, such as calipers and rulers.

- I also use a magnifying glass to ensure that the details of the design are correct.

9. How do you polish a seal?

- I polish a seal by using a variety of polishing wheels and compounds.

- I start with a coarse polishing wheel and compound, and then I gradually switch to finer polishing wheels and compounds.

- I continue polishing the seal until it is smooth and shiny.

10. What are the different types of seals that you can make?

- I can make a variety of different types of seals, including: wax seals, ink seals, and embossing seals.

- Wax seals are used to seal letters and documents, while ink seals are used to stamp paper.

- Embossing seals are used to create raised impressions on paper.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seals Engraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seals Engraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Seals Engravers are skilled artisans who create custom seals and stamps for a variety of purposes, including official documents, personal stationery, and jewelry. Their key job responsibilities include:

1. Designing and Creating Custom Seals and Stamps

Seals Engravers use a variety of techniques to design and create custom seals and stamps, including hand carving, laser engraving, and photo engraving. They work closely with clients to understand their needs and create a design that meets their specific requirements.

- Meet with clients to discuss their needs

- Create design sketches

- Carve or engrave seals and stamps

- Inspect finished products to ensure quality

2. Maintaining Equipment and Tools

Seals Engravers must maintain their equipment and tools in good working order to ensure the quality of their work. This includes cleaning and sharpening tools, and calibrating machines.

- Clean and sharpen tools

- Calibrate machines

- Order supplies

3. Providing Customer Service

Seals Engravers often work directly with clients, so they must be able to provide excellent customer service. This includes answering questions, resolving complaints, and providing advice on seal and stamp design.

- Answer questions from clients

- Resolve complaints

- Provide advice on seal and stamp design

4. Staying Up-to-Date on Industry Trends

Seals Engravers must stay up-to-date on industry trends and new technologies to ensure that they are providing the best possible service to their clients. This includes attending trade shows, reading industry publications, and networking with other professionals.

- Attend trade shows

- Read industry publications

- Network with other professionals

Interview Tips

To ace an interview for a Seals Engraver position, it is important to be prepared to discuss your skills and experience in detail. You should also be able to demonstrate your knowledge of the industry and your commitment to providing excellent customer service.

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Network with people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about your experience in seal engraving” and “What are your strengths and weaknesses?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer questions

- Be specific and provide examples

- Tailor your answers to the specific requirements of the job

3. Bring a Portfolio of Your Work

If you have any examples of your work, such as custom seals or stamps that you have created, be sure to bring them to your interview. This will give the interviewer a chance to see your skills and craftsmanship firsthand.

- Include a variety of examples

- Label your work with your name and contact information

- Be prepared to discuss your work in detail

4. Dress Professionally and Be Punctual

First impressions matter, so it is important to dress professionally and arrive for your interview on time. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear business attire

- Be on time for your interview

- Make eye contact and smile

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Seals Engraver, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Seals Engraver positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.