Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Seam Closer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Seam Closer so you can tailor your answers to impress potential employers.

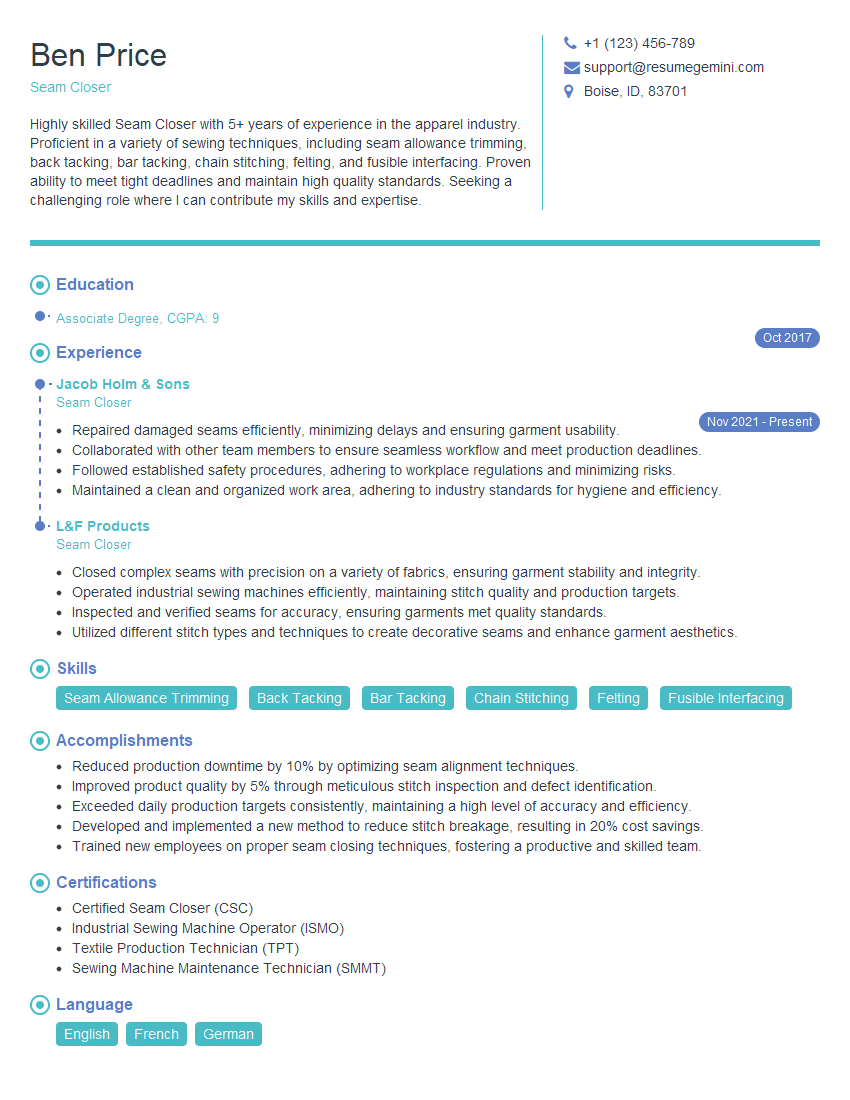

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seam Closer

1. Describe the process of joining two pieces of fabric using a sewing machine?

To flawlessly join two pieces of fabric using a sewing machine, I meticulously follow these steps:

- Fabric Preparation: I ensure the fabric edges to be joined are clean and straight by trimming away any loose threads or uneven areas.

- Seam Allowance: I determine the desired seam allowance and mark it evenly on both fabric pieces using a measuring tape or marking tool.

- Pinning: I carefully align the fabric pieces right sides together, matching the marked seam allowances, and secure them with pins perpendicular to the seam line.

- Sewing: With the machine set to the appropriate stitch type and tension, I stitch along the pinned seam line, maintaining a consistent stitch length and even pressure.

- Finishing: Once sewn, I remove the pins and press the seam open using an iron to flatten and set it.

2. What types of stitches are used in seam closing and when should each be used?

Straight Stitch:

- A universal stitch suitable for most fabrics.

- Strong and durable, making it ideal for general seam closing.

Zigzag Stitch:

- Used to prevent fraying and provide stretch in seams.

- Suitable for stretchy fabrics, knitwear, and finishing raw edges.

Serged Stitch:

- A fast and efficient method for finishing seams and preventing fraying.

- Typically used in garment construction and on fabrics that prone to unraveling.

3. How do you troubleshoot a sewing machine that is causing skipped stitches?

To effectively troubleshoot skipped stitches, I take the following steps:

- Check Threading: I verify that the machine is correctly threaded, ensuring the thread passes through all the tension discs and guides.

- Adjust Tension: I adjust the upper and lower thread tensions as per the manufacturer’s recommendations.

- Clean and Oil: I clean and oil the machine, particularly the bobbin area and needle, to remove any lint or debris that may interfere with smooth operation.

- Replace Needle: If the needle is bent or damaged, I replace it with a new one of the correct size and type.

- Check Fabric Thickness: I ensure the fabric is not too thick for the machine or needle being used, as this can cause the machine to struggle and skip stitches.

4. What safety precautions are important to observe when operating a sewing machine?

- Always keep hands and fingers away from the needle and moving parts.

- Use a finger guard or thimble when handling sharp needles or fabrics.

- Keep the work area clean and well-lit to prevent accidents.

- Unplug the machine when not in use or when changing needles or bobbins.

- Follow the manufacturer’s instructions for proper machine operation and maintenance.

5. How do you maintain a clean and organized sewing workstation?

- Regularly clean the machine and work surface to remove lint, thread, and fabric scraps.

- Store fabrics, threads, and tools in designated areas to maintain organization.

- Dispose of fabric scraps and waste properly to prevent clutter.

- Use a lint brush or vacuum cleaner to remove dust and debris from the machine and work area.

- Keep cords and cables organized and out of the way to prevent tripping hazards.

6. What is the importance of regular machine maintenance?

- Extends the machine’s lifespan by reducing wear and tear.

- Prevents costly repairs by identifying and addressing minor issues early on.

- Ensures consistent stitch quality and optimal machine performance.

- Improves safety by minimizing the risk of accidents or malfunctions.

- Maintains the machine’s warranty and value.

7. How do you determine the correct needle size for different fabric types?

The appropriate needle size depends on the fabric’s thickness, weave, and fiber content:

- Thin and delicate fabrics (e.g., silk, chiffon): Size 60/8 or 70/10

- Medium-weight fabrics (e.g., cotton, linen, denim): Size 80/12 or 90/14

- Thick and heavy fabrics (e.g., canvas, leather, upholstery): Size 100/16 or 110/18

8. What techniques can be used to achieve a professional and durable finish on seams?

- Pinked Seams: Cutting the seam allowance with pinking shears prevents fraying and gives a clean finish.

- Overcasting: Using a zigzag stitch to cover the raw edge of a seam provides reinforcement and prevents unraveling.

- Topstitching: Reinforcing seams by stitching along the seam line from the right side of the fabric.

- Seam Binding: Covering raw edges with a strip of fabric or bias tape to provide a professional and decorative finish.

9. How do you handle working with difficult fabrics, such as slippery or stretchy materials?

To effectively work with challenging fabrics:

- Slippery Fabrics: Use a walking foot or Teflon foot to prevent the fabric from slipping under the needle.

- Stretchy Fabrics: Use a stretch stitch or adjust the machine tension to accommodate the fabric’s elasticity.

- Delicate Fabrics: Handle with care, use a fine needle, and adjust the machine settings accordingly.

10. Describe a situation where you encountered a problem with a sewing machine and how you resolved it.

In a previous role, I encountered an issue where the sewing machine was producing uneven stitches. After troubleshooting, I realized the needle was slightly bent. I promptly replaced the needle with a new one of the correct size, and the machine began functioning smoothly again.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seam Closer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seam Closer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Seam Closer is responsible for joining fabrics together using a sewing machine. They ensure that the seams are strong and durable, and align patterns and colors accurately. Additionally, they may also perform other tasks such as inspecting garments and textiles for defects, and assisting with finishing processes.

1. Sewing Seams

Using a sewing machine, Seam Closers sew seams on garments and other textile products. They ensure that the seams are even and strong, and that they align patterns and colors accurately. This requires precision and attention to detail.

- Sewing seams on garments, such as shirts, pants, and dresses.

- Joining fabric pieces for upholstery, curtains, and other home furnishings.

2. Inspecting Garments and Textiles

Seam Closers inspect garments and textiles for defects, such as rips, tears, or uneven seams. They may also check for color matching and pattern alignment. This requires a keen eye for detail and a good understanding of garment construction.

- Inspecting garments for defects, such as rips, tears, or uneven seams.

- Checking color matching and pattern alignment.

3. Assisting with Finishing Processes

Seam Closers may also assist with finishing processes, such as pressing and packaging garments. This requires a basic understanding of garment finishing techniques and equipment.

- Pressing garments to remove wrinkles and creases.

- Packaging garments for storage or shipment.

Interview Tips

Preparing for an interview for a Seam Closer position requires research, practice, and confidence. Here are some tips to help you ace your interview:

1. Research the company and the position

Take the time to learn about the company you’re applying to and the specific Seam Closer position you’re interested in. This will help you understand the company’s culture, values, and the specific requirements of the role. You can find this information on the company’s website, social media pages, and job boards.

- Visit the company’s website to learn about their history, mission, and products or services.

- Check out the company’s social media pages to get a sense of their culture and values.

- Read the job description carefully to understand the specific requirements of the role.

2. Practice your answers to common interview questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself, including your skills, experience, and why you’re interested in the position.

- Practice answering questions about your experience with sewing machines and garment construction.

- Be prepared to discuss your attention to detail and ability to work independently.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothing that is appropriate for a work environment. You should also arrive on time for your interview, as punctuality shows respect for the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for a work environment.

- Arrive for your interview on time, or even a few minutes early.

4. Be confident and enthusiastic

Confidence is key in any interview, and it’s especially important for a Seam Closer position. Employers want to see that you’re confident in your abilities and that you’re excited about the opportunity to work for their company. Be sure to make eye contact with the interviewer, speak clearly and confidently, and smile. Your enthusiasm will show the interviewer that you’re genuinely interested in the position and that you’re eager to learn and grow.

- Make eye contact with the interviewer and speak clearly and confidently.

- Smile and show your enthusiasm for the position.

- Be prepared to ask questions about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Seam Closer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!