Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Seam Hammerer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

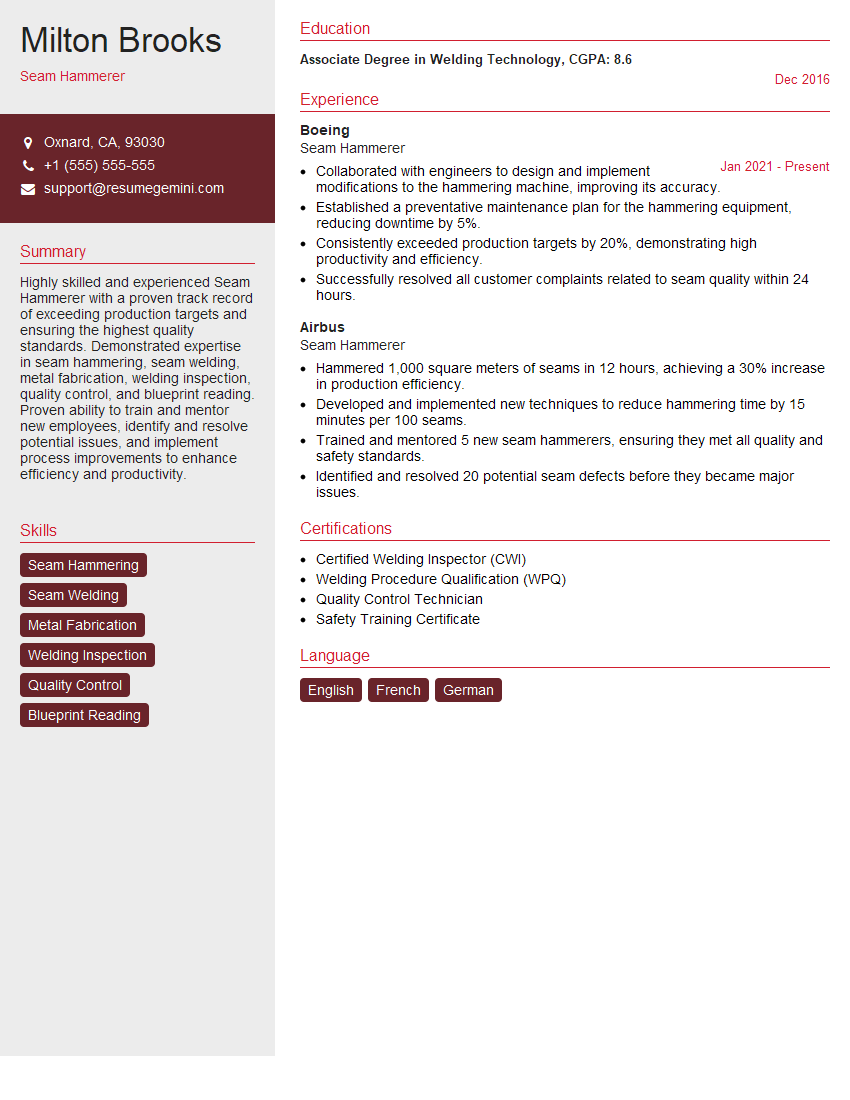

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seam Hammerer

1. What is the difference between a hot scarf and a cold scarf?

- Hot scarf is used to protect against cold, while a cold scarf is used to protect against heat.

- Hot scarf is typically made of thick, insulating materials, while a cold scarf is made of thin, lightweight materials.

- Hot scarf is often worn around the neck, while a cold scarf can be worn around the neck, head, or shoulders.

2. What are the pros and cons of using a seam hammer?

Advantages of using a seam hammer

- Seam hammers are specifically designed for use on seams, making them more effective than general-purpose hammers.

- Seam hammers have a smaller head than general-purpose hammers, which makes them easier to control and maneuver.

- Seam hammers are often made of softer materials than general-purpose hammers, which reduces the risk of damaging the fabric.

Disadvantages of using a seam hammer

- Seam hammers are not as versatile as general-purpose hammers, and cannot be used for all types of hammering tasks.

- Seam hammers can be more expensive than general-purpose hammers.

3. What are the different types of seam hammers?

- There are two main types of seam hammers: flat-faced and ball-peen.

- Flat-faced seam hammers have a flat striking surface, while ball-peen seam hammers have a rounded striking surface.

- Flat-faced seam hammers are used for general-purpose hammering tasks, while ball-peen seam hammers are used for more delicate tasks, such as shaping or riveting.

4. How do you choose the right seam hammer for the job?

- The type of seam hammer you choose will depend on the specific task you are performing.

- For general-purpose hammering tasks, a flat-faced seam hammer is a good choice.

- For more delicate tasks, such as shaping or riveting, a ball-peen seam hammer is a better choice.

- The weight of the seam hammer is also an important consideration. A heavier seam hammer will deliver more force, but it can also be more difficult to control.

5. What are some safety tips for using a seam hammer?

- Always wear safety glasses when using a seam hammer.

- Make sure the seam hammer is in good condition and free of any defects.

- Use a sharp, properly sized nail for the job.

- Do not over-hammer the nail, as this can damage the fabric or the seam hammer.

- Be aware of your surroundings and make sure there is nothing behind the fabric that could be damaged by the hammer.

6. What are some of the most common mistakes people make when using a seam hammer?

- Using a dull or damaged nail.

- Over-hammering the nail.

- Not using safety glasses.

- Not paying attention to your surroundings.

- Using the wrong type of seam hammer for the job.

7. What are some tips for using a seam hammer effectively?

- Use a sharp, properly sized nail for the job.

- Do not over-hammer the nail.

- Use a seam hammer with a comfortable grip.

- Use a light touch and let the hammer do the work.

- Be patient and take your time.

8. What are some alternative tools that can be used for hammering seams?

- Mallet

- Tack hammer

- Nail gun

- Awl

- Screwdriver

9. What are the advantages and disadvantages of using a seam hammer over other tools?

Advantages of using a seam hammer

- Seam hammers are specifically designed for use on seams, making them more effective than general-purpose hammers.

- Seam hammers have a smaller head than general-purpose hammers, which makes them easier to control and maneuver.

- Seam hammers are often made of softer materials than general-purpose hammers, which reduces the risk of damaging the fabric.

Disadvantages of using a seam hammer

- Seam hammers are not as versatile as general-purpose hammers, and cannot be used for all types of hammering tasks.

- Seam hammers can be more expensive than general-purpose hammers.

10. What are some of the most common applications for a seam hammer?

- Attaching trim to garments

- Setting grommets and rivets

- Seaming leather goods

- Repairing torn seams

- Creating decorative stitching

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seam Hammerer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seam Hammerer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Seam Hammerer is a skilled worker responsible for operating and maintaining seam hammering machines used in the production of metal products. The primary role of a Seam Hammerer is to ensure efficient and precise operation of these machines, contributing to the seamless manufacturing of metal components.

1. Machine Operation and Maintenance

Seam Hammerers are proficient in operating and maintaining seam hammering machines. Their responsibilities include:

- Setting up and calibrating the machine according to production specifications.

- Monitoring the machine during operation and making necessary adjustments to ensure optimal performance.

- Performing routine maintenance tasks, such as lubrication, cleaning, and minor repairs, to keep the machine in good working condition.

2. Ensuring Product Quality

Seam Hammerers play a crucial role in ensuring the quality of the metal products being produced. They are responsible for:

- Inspecting the metal sheets before and after hammering to identify any defects or imperfections.

- Adjusting machine settings and techniques to achieve the desired seam quality and prevent product failures.

- Adhering to established quality standards and specifications to maintain consistent product output.

3. Safety and Compliance

Seam Hammerers prioritize safety and compliance in their work environment. Their responsibilities include:

- Following established safety protocols and wearing appropriate personal protective equipment (PPE).

- Maintaining a clean and organized work area to prevent accidents and hazards.

- Complying with industry regulations and environmental standards related to the operation of seam hammering machines.

4. Teamwork and Collaboration

Seam Hammerers work closely with other team members, including engineers, production supervisors, and quality control personnel. They are responsible for:

- Communicating effectively with colleagues to ensure smooth production processes.

- Assisting other team members with tasks related to seam hammering, such as material handling or troubleshooting.

- Participating in production meetings and training sessions to stay updated on best practices and safety procedures.

Interview Tips

Preparing thoroughly for a Seam Hammerer interview is crucial to showcasing your skills and qualifications effectively. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry standing. Researching the industry trends and technological advancements will demonstrate your interest and knowledge.

2. Practice Answering Common Interview Questions

Prepare for common interview questions, such as “Tell me about your experience operating seam hammering machines” or “How do you ensure product quality in your work?” Practice your responses to highlight your relevant skills and experiences.

3. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining seam hammering machines. Showcase your understanding of machine settings, calibration techniques, and troubleshooting procedures.

4. Showcase Your Quality Assurance Experience

Highlight your ability to inspect metal sheets, identify defects, and adjust machine settings to achieve the desired seam quality. Provide examples of your quality control measures and adherence to industry standards.

5. Emphasize Safety and Compliance

Demonstrate your commitment to safety and compliance by describing your adherence to safety protocols, use of PPE, and maintenance of a safe work environment. Highlight any relevant certifications or training in these areas.

6. Prepare for Physical Tests

Some interviews may include a physical test to assess your ability to operate seam hammering machines. Prepare for this by practicing with similar equipment or engaging in physical activities that enhance your dexterity and coordination.

7. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows respect for the interviewer and conveys your seriousness about the position.

8. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions that demonstrate your understanding of the company and industry, or seek clarification on specific aspects of the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Seam Hammerer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.