Are you gearing up for a career in Seat Cover Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Seat Cover Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

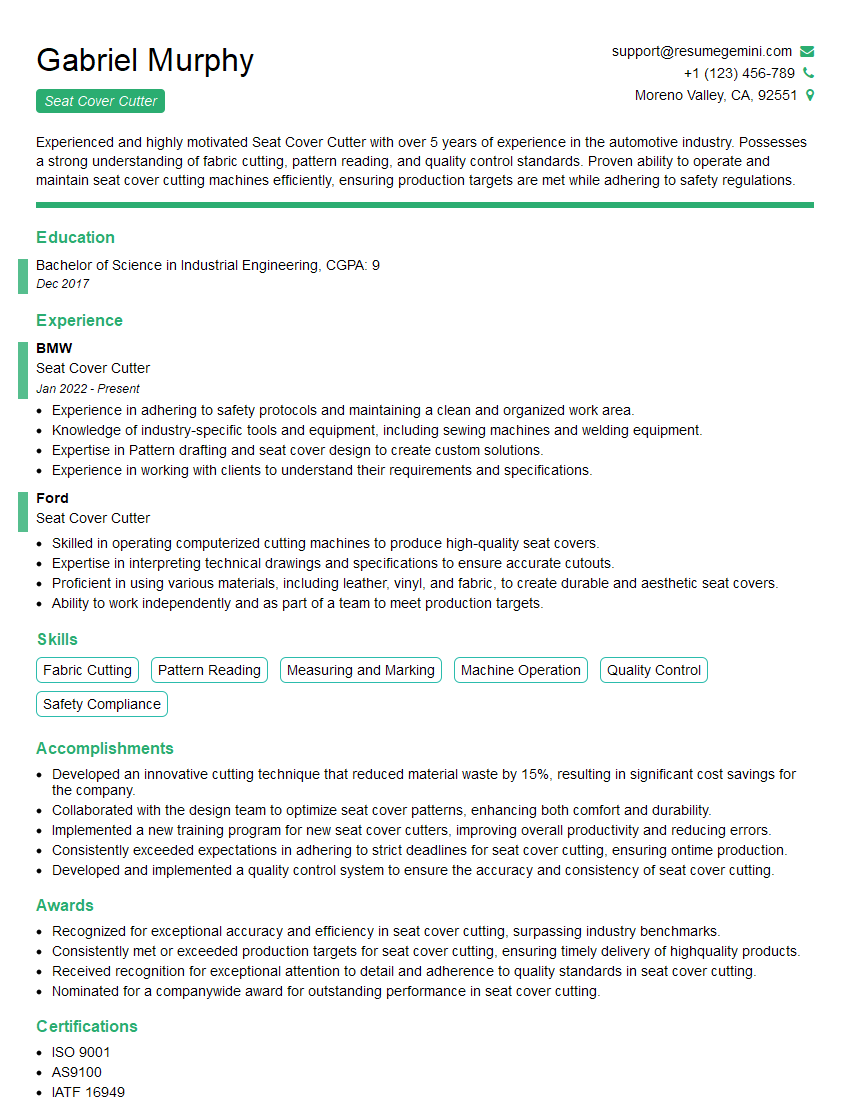

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seat Cover Cutter

1. Describe the process of cutting seat covers from a pattern.

The process of cutting seat covers from a pattern involves several steps to ensure accuracy and precision.

- Laying Out the Fabric: The fabric is spread out on a flat surface, ensuring that it is smooth and free of any wrinkles or creases.

- Positioning the Pattern: The pattern is placed on the fabric, aligning it carefully to achieve the desired placement and orientation.

- Securing the Pattern: The pattern is held in place using pins or weights to prevent it from shifting during the cutting process.

- Cutting the Fabric: Using sharp scissors or a rotary cutter, the fabric is cut along the pattern’s edges, following the designated seam allowance.

- Inspecting the Cut Pieces: Once cut, the fabric pieces are inspected for accuracy, ensuring that they match the pattern and are free of any defects or uneven edges.

2. What factors influence the choice of cutting method for seat covers?

The choice of cutting method for seat covers is influenced by several key factors:

- Type of Fabric: Different fabrics have unique properties that dictate the appropriate cutting method. For example, delicate fabrics may require more precision while heavier fabrics may benefit from a more robust approach.

- Volume of Production: The scale of production influences the cutting method. High-volume production often necessitates automated cutting systems, while smaller-scale production may rely on manual cutting.

- Accuracy and Precision: The desired level of accuracy and precision in the cut pieces determines the choice of cutting method. Automated systems generally offer greater precision than manual cutting.

- Cost and Efficiency: Cutting method selection also considers cost and efficiency. Manual cutting may be more economical for small-scale production, while automated systems can enhance efficiency for larger volumes.

3. How do you ensure the quality of cut seat covers?

Ensuring the quality of cut seat covers requires a comprehensive approach that involves:

- Sharp Cutting Tools: Using sharp scissors or rotary cutters maintains clean and precise cuts, reducing the risk of frayed edges or uneven cuts.

- Accurate Measurement and Alignment: Careful measurement and alignment of the pattern on the fabric is crucial to ensure consistency and accuracy in the cut pieces.

- Regular Inspection: Regular inspection of cut pieces throughout the process allows for prompt identification and correction of any errors or defects.

- Quality Control Measures: Implementing quality control measures, such as sampling and measurement verification, helps maintain consistent quality standards.

- Training and Skill: Providing adequate training to cutters and maintaining their skills through ongoing development ensures proficiency in cutting techniques.

4. What types of seat cover materials are commonly used, and how do they impact the cutting process?

Commonly used seat cover materials include:

- Leather: Leather requires specialized cutting techniques due to its durability and thickness. Sharp blades and proper cutting pressure are essential to achieve clean cuts.

- Vinyl: Vinyl is a versatile material that is relatively easy to cut. However, it can be prone to fraying, so care must be taken to use sharp blades and avoid overcutting.

- Fabric: Fabrics such as cotton, polyester, and nylon are commonly used for seat covers. The choice of cutting method depends on the specific fabric’s properties and thickness.

- Synthetic Leather: Synthetic leather offers a similar look and feel to leather but is generally easier to cut. It may require specialized blades or techniques to achieve the desired finish.

5. Describe the use of digital cutting machines in the seat cover manufacturing process.

Digital cutting machines bring several advantages to the seat cover manufacturing process:

- Accuracy and Precision: Digital machines utilize computer-controlled cutting, ensuring highly accurate and precise cuts, reducing the risk of errors.

- Consistency: Automated cutting eliminates manual variations, resulting in consistent cut quality and reduced waste.

- Speed and Efficiency: Digital machines can operate at high speeds, increasing production efficiency and reducing lead times.

- Integration with Design: Digital cutting machines can be integrated with computer-aided design (CAD) software, allowing for seamless transfer of design data and automated cutting.

6. How do you handle variations in seat cover design and dimensions?

To handle variations in seat cover design and dimensions, I employ the following strategies:

- Pattern Customization: I adjust the cutting patterns to accommodate specific seat dimensions and design requirements, ensuring a precise fit.

- Manual Adjustments: For complex or unique designs, I utilize manual cutting techniques to make precise adjustments and ensure a perfect fit.

- Collaboration with Designers: I collaborate closely with designers to understand the design intent and develop cutting strategies that meet their specifications.

7. What are the safety precautions to consider when operating cutting machines?

To ensure safety when operating cutting machines, I strictly adhere to the following precautions:

- Proper Training: I undergo thorough training to fully understand the machine’s operation and safety features.

- Protective Gear: I wear appropriate protective gear, including safety glasses, gloves, and earplugs, to minimize the risk of injury.

- Machine Maintenance: I perform regular maintenance on cutting machines to ensure they are in good working condition and free of any defects.

- Safe Work Environment: I maintain a clean and organized work area, free from clutter and potential tripping hazards.

8. How do you manage and minimize fabric waste during the cutting process?

To minimize fabric waste during the cutting process, I implement the following strategies:

- Efficient Pattern Layout: I carefully plan the layout of patterns on the fabric to maximize material utilization and reduce waste.

- Nested Cutting: I utilize nesting software to optimize the placement of patterns on the fabric, reducing the amount of unused material.

- Remnant Utilization: I collect and utilize leftover fabric scraps for smaller items or as padding material.

9. What are the techniques you use to ensure accuracy in cutting seat covers?

To ensure accuracy in cutting seat covers, I employ several techniques, including:

- Measuring and Marking: I carefully measure and mark the fabric before cutting, ensuring precise alignment and dimensions.

- Straight Edge and Rulers: I utilize straight edges and rulers to guide my cuts, minimizing deviations and ensuring straight lines.

- Templates: For complex shapes or curves, I create templates to ensure accurate cutting and consistency.

10. How do you handle the challenge of cutting different types of seat covers, such as those for cars, motorcycles, and boats?

I adapt my cutting techniques based on the specific requirements of different types of seat covers:

- Automotive Seat Covers: Automotive seat covers often require precision cuts to fit complex shapes and contours. I use specialized patterns and cutting tools to achieve the necessary accuracy.

- Motorcycle Seat Covers: Motorcycle seat covers typically involve cutting thicker and more durable materials. I adjust my cutting pressure and blade sharpness accordingly.

- Boat Seat Covers: Boat seat covers may require water-resistant materials. I select appropriate cutting tools and techniques to prevent fraying or damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seat Cover Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seat Cover Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Seat Cover Cutter is a vital member of the manufacturing team, responsible for cutting seat covers precisely and accurately to ensure a high-quality finished product.

1. Cut Seat Covers According to Specifications

Interpret blueprints and patterns to accurately cut seat covers from various materials, including leather, vinyl, and fabric.

- Operate cutting equipment safely and efficiently to cut seat covers to exact measurements.

- Inspect cut seat covers for accuracy and quality before transferring them to the assembly line.

2. Maintain Equipment and Work Area

Perform regular maintenance and cleaning of cutting equipment to ensure optimal operation and accuracy.

- Keep work area clean and organized to prevent accidents and ensure efficient work flow.

- Report any equipment malfunctions or safety concerns to supervisors promptly.

3. Adhere to Safety Protocols

Follow all safety regulations and guidelines established by the company and industry standards.

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs, to minimize risks.

- Operate equipment only when properly trained and authorized.

4. Work Effectively in a Team Environment

Collaborate with production team members to ensure seamless operation and timely completion of orders.

- Communicate effectively with colleagues and supervisors to avoid errors and maintain a positive work environment.

- Assist other team members when needed to achieve production goals.

Interview Tips

Preparing for a Seat Cover Cutter interview requires researching the role, understanding the key responsibilities, and practicing your responses to common interview questions.

1. Research the Role and Company

Thoroughly read the job description and visit the company’s website to gain a clear understanding of the specific responsibilities and qualifications required for the position.

- Identify the key skills and experience highlighted in the job description.

- Research the company’s industry, products, and values to demonstrate your interest and knowledge.

2. Practice Answering Common Interview Questions

Anticipate questions about your technical skills, experience, and safety awareness. Prepare concise and specific answers that showcase your abilities and align with the job requirements.

- Explain your experience in cutting seat covers using various materials and equipment.

- Describe your understanding of safety protocols and how you maintain a safe work environment.

3. Highlight Your Attention to Detail and Accuracy

Emphasize your attention to detail and ability to work accurately within tight tolerances. Provide examples of how you ensure the precision of cut seat covers and maintain high standards.

- Describe your process for inspecting cut seat covers and identifying potential errors.

- Share any experience using measuring tools, templates, or software to achieve precise cuts.

4. Showcase Your Teamwork and Communication Skills

Demonstrate your ability to work effectively in a team environment and communicate clearly with colleagues. Provide examples of how you collaborate with others and contribute to the success of the production line.

- Describe your experience working with production team members to troubleshoot problems and meet deadlines.

- Explain how you maintain open communication to avoid errors and ensure smooth operation.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Seat Cover Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Seat Cover Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.