Are you gearing up for a career in Seat Coverer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Seat Coverer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

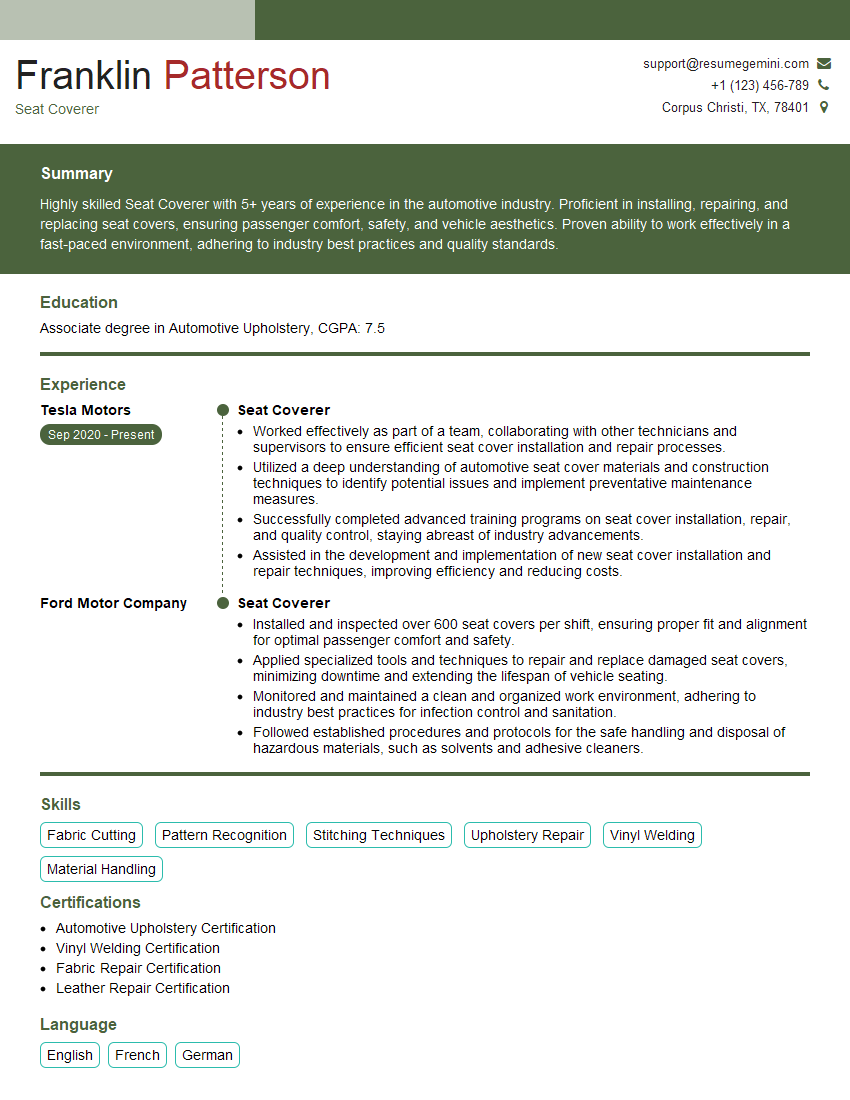

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seat Coverer

1. How do you ensure the proper fitment of seat covers for different types of seats?

To ensure proper fitment, I follow these steps:

- Identify the seat type: I carefully examine the vehicle’s seats to determine their size, shape, and any special features.

- Select the appropriate cover: Using my knowledge of seat types and cover dimensions, I choose the cover that is best suited for the specific seats.

- Follow installation instructions: I meticulously follow the manufacturer’s instructions for fitting the cover, ensuring a snug and secure installation.

- Test the fit: Once installed, I sit in the seat and check for any wrinkles, bulges, or discomfort. I adjust the cover as necessary for an optimal fit.

2. What materials are commonly used in seat covers and what are their advantages and disadvantages?

Natural Materials

- Leather: Durable, luxurious, breathable, but expensive and requires regular care.

- Cotton: Soft, comfortable, affordable, but prone to wrinkles and fading.

Synthetic Materials

- Polyester: Water-resistant, stain-resistant, durable, but can feel less breathable than natural materials.

- Neoprene: Waterproof, durable, elastic, but can be warm and uncomfortable in hot weather.

Blended Materials

- Leather-Vinyl: Combines the durability of leather with the ease of cleaning of vinyl.

- Cotton-Polyester: Offers the comfort of cotton with the durability of polyester.

3. How do you handle customer requests for custom seat covers?

When handling requests for custom seat covers, I prioritize the following steps:

- Gather requirements: I engage in detailed communication with the customer to understand their specific needs, including the desired fabric, color, pattern, and any additional features.

- Assess feasibility: I evaluate the feasibility of the request based on my knowledge of available materials and techniques.

- Develop a design: If the request is feasible, I work collaboratively with the customer to develop a design that meets their vision.

- Obtain approval: Once the design is finalized, I present it to the customer for approval before proceeding with production.

4. What techniques do you use to repair torn or damaged seat covers?

To repair torn or damaged seat covers, I employ the following techniques:

- Patching: I cut a patch of fabric from a similar material and use adhesive or stitching to attach it over the torn area.

- Stitching: If the tear is clean and straight, I carefully stitch it back together using a needle and thread.

- Leather repair: For leather covers, I use specialized leather repair kits that involve patching, cleaning, and conditioning the damaged area.

- Re-upholstery: In cases of extensive damage, I may need to re-upholster the seat cover with a new fabric or leather.

5. How do you stay up-to-date on the latest trends and technologies in seat cover design and materials?

To stay abreast of industry advancements, I engage in ongoing professional development activities:

- Attend trade shows: I visit industry trade shows to witness firsthand the latest innovations and connect with manufacturers.

- Read industry publications: I subscribe to industry magazines and online resources to stay informed about new materials, techniques, and design trends.

- Network with professionals: I actively participate in industry forums and online communities to exchange ideas and knowledge with other seat cover professionals.

6. What safety precautions do you take when working with seat covers?

Safety is paramount in my work as a seat coverer, and I adhere to the following precautions:

- Wear protective gear: I always wear gloves, eye protection, and a mask when handling chemicals or working with sharp objects.

- Use sharp tools safely: I keep cutting tools sharp and handle them with care to prevent accidents.

- Maintain a clean workspace: I keep my work area tidy and free of tripping hazards to ensure a safe working environment.

7. How do you ensure quality control in your work?

To ensure the highest quality in my work, I follow these quality control measures:

- Thorough inspection: Before installing any seat covers, I meticulously inspect them for any defects or imperfections.

- Test fit: I conduct a thorough test fit of the covers on the seats to ensure proper alignment, fit, and functionality.

- Customer satisfaction: I prioritize customer satisfaction by listening to their feedback and ensuring their expectations are met.

8. What are the common challenges you encounter as a seat coverer and how do you overcome them?

As a seat coverer, I encounter various challenges, and I handle them with these strategies:

- Complex seat designs: I carefully study the unique features of each seat and adapt my installation techniques accordingly.

- Unusual materials: When working with unconventional materials, I research and test different methods to ensure a durable and aesthetically pleasing installation.

- Time constraints: I efficiently manage my time by prioritizing tasks and utilizing efficient installation techniques.

9. What is your approach to troubleshooting installation or repair issues?

When faced with installation or repair issues, I take a systematic approach:

- Identify the root cause: I thoroughly examine the issue to determine its underlying cause.

- Consider alternative solutions: I explore multiple solutions and select the most effective and efficient approach.

- Implement the solution: I carefully implement the chosen solution, ensuring that the issue is resolved effectively.

- Test and verify: I conduct thorough testing to verify that the issue has been fully addressed.

10. How do you handle customer complaints or dissatisfaction?

When addressing customer complaints or dissatisfaction, I prioritize the following:

- Active listening: I attentively listen to the customer’s concerns and acknowledge their perspective.

- Empathy: I demonstrate understanding and empathy towards the customer’s situation.

- Problem-solving: I work collaboratively with the customer to identify the root cause of the issue and develop a mutually acceptable solution.

- Follow-up: I ensure prompt follow-up to keep the customer informed and address any additional concerns.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seat Coverer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seat Coverer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Seat Coverer, you will be responsible for various tasks related to the production and maintenance of seat covers for automobiles.

1. Seat Cover Production

You will be involved in cutting, fitting, and sewing seat covers according to established specifications and customer requirements.

2. Upholstery Maintenance

Additionally, you will be responsible for repairing and maintaining seat covers, making sure they remain in good condition.

3. Fabric Handling

You will be managing and handling various fabrics used in the production of seat covers, such as leather, vinyl, and cloth.

4. Machine Operation

You will be operating sewing machines and other related equipment to ensure efficient production and maintenance of seat covers.

Interview Tips

To ace the interview for a Seat Coverer position, here are some valuable tips:

1. Research Industry Knowledge

Be familiar with the automotive industry, the materials and techniques used in seat cover production, and any industry-specific trends.

2. Showcase Relevant Experience

Highlight any previous experience you have in seat cover production, upholstery maintenance, or related fields.

3. Prepare for Technical Questions

Expect questions related to fabric handling, machine operation, and upholstery maintenance techniques.

4. Emphasize Attention to Detail

Convey your keen attention to detail and meticulous approach to ensuring the quality of seat covers.

5. Practice Your Skills

If possible, practice your sewing and upholstery skills before the interview to demonstrate your proficiency.

Next Step:

Now that you’re armed with the knowledge of Seat Coverer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Seat Coverer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini