Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Seater Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

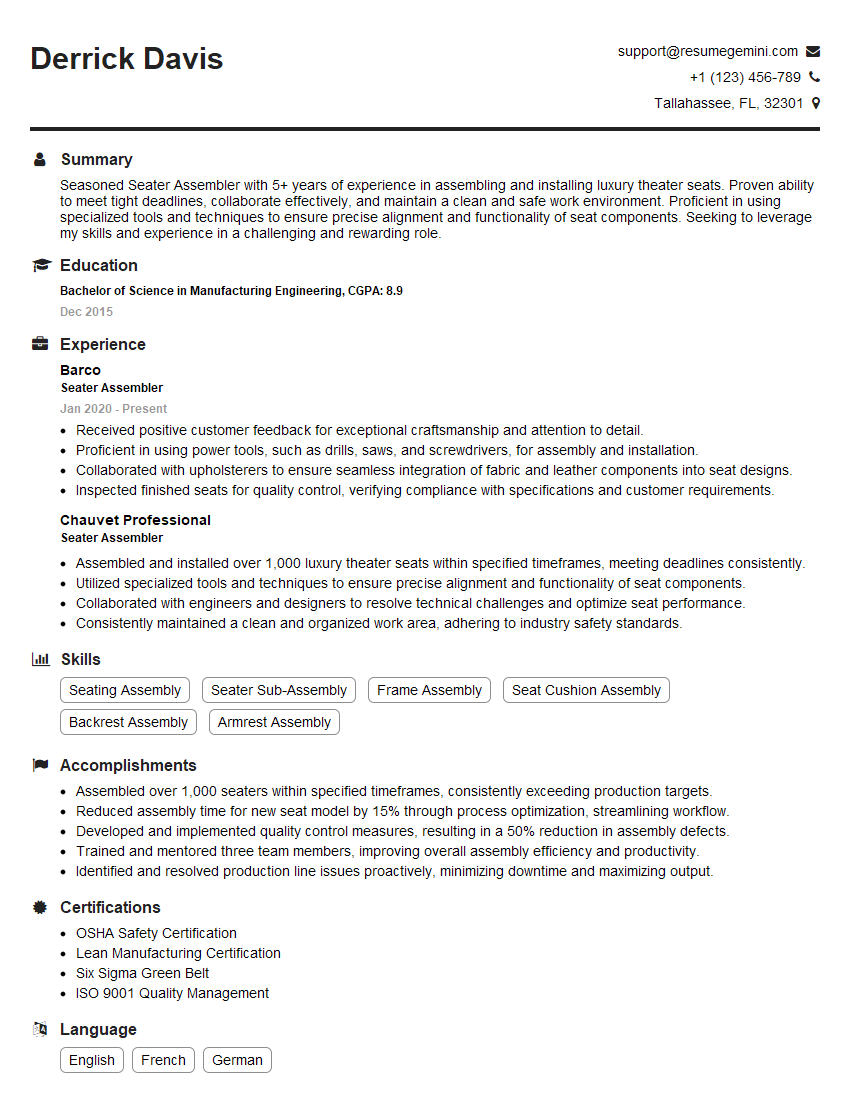

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seater Assembler

1. Explain the process of assembling a seater?

The process of assembling a seater involves several steps:

- Prepare the frame: Inspect the frame for any damage or defects. Attach the legs to the frame using bolts or screws.

- Install the seat cushions: Place the seat cushions on the frame and secure them using straps or clips.

- Install the backrest: Attach the backrest to the frame using bolts or screws. Ensure that the backrest is aligned properly.

- Install the armrests: Attach the armrests to the frame using bolts or screws. Make sure that the armrests are level and secure.

- Check and inspect: Inspect the assembled seater to ensure that all components are fitted correctly and securely. Conduct a final quality check to ensure the seater meets specifications.

2. What types of materials are used in the production of seaters?

The materials used in the production of seaters vary depending on the desired quality, durability, and budget:

Upholstery:

- Leather: Durable, luxurious, and easy to clean.

- Fabric: Variety of colors, textures, and patterns; more affordable than leather.

- Vinyl: Waterproof, stain-resistant, and easy to maintain.

Frame:

- Wood: Strong, durable, and can be stained or painted.

- Metal: Lightweight, durable, and can be powder-coated for corrosion resistance.

- Plastic: Lightweight, affordable, and can be molded into various shapes.

Cushioning:

- Foam: Provides comfort and support; comes in various densities.

- Down feathers: Luxurious, soft, and breathable.

- Springs: Supports the cushions and provides a bouncy feel.

3. Describe the safety precautions to be observed when working with seaters?

- Wear appropriate safety gear: Safety glasses, gloves, and sturdy shoes to prevent injuries.

- Use sharp tools with care: Handle knives and scissors carefully to avoid cuts.

- Avoid lifting heavy objects alone: Ask for assistance when moving heavy seaters or components.

- Maintain a clean work area: Clear away clutter and debris to prevent tripping hazards.

- Be aware of electrical hazards: Ensure proper grounding and avoid contact with exposed wires.

4. How do you troubleshoot common issues faced during seater assembly?

- Loose or squeaky joints: Tighten bolts or screws. Apply lubricant if necessary.

- Uneven or sagging cushions: Adjust the cushion straps or clips. Replace cushions if damaged.

- Torn or damaged upholstery: Repair or replace the upholstery as needed.

- Wobbling or unstable seater: Check the leg attachments and frame for damage. Repair or replace as necessary.

- Electrical issues: Inspect wires and connections. Contact an electrician if the issue persists.

5. What techniques do you use to ensure the quality of assembled seaters?

- Follow detailed assembly instructions: Ensure compliance with specifications.

- Inspect components before assembly: Check for defects or damage.

- Use precision tools and equipment: Ensure accurate measurements and fittings.

- Test the finished product: Sit on the seater to check for comfort and stability.

- Seek feedback from users: Gather input to identify areas for improvement.

6. How do you stay updated on the latest techniques and materials used in seater assembly?

- Attend industry workshops and seminars: Learn about new trends and advancements.

- Read industry publications and online resources: Stay informed about best practices.

- Consult with material suppliers: Seek information on the latest materials and their applications.

- Attend training sessions provided by manufacturers: Gain knowledge on specific products and techniques.

- Network with other professionals: Share knowledge and experiences within the industry.

7. Describe your experience in working with different types of seating products.

Throughout my career as a Seater Assembler, I have worked with a wide range of seating products, including:

- Residential sofas and chairs: Assembled various styles and sizes for home use.

- Commercial office chairs: Built ergonomic chairs designed for prolonged sitting.

- Medical seating: Assembled specialized chairs for hospitals and medical facilities.

- Automotive seating: Worked on seats for cars, trucks, and buses.

- Outdoor seating: Assembled weather-resistant seating for patios, decks, and gardens.

8. How do you ensure that the assembled seaters meet the specified quality standards?

- Adhere to detailed assembly instructions and specifications: Follow the provided guidelines precisely.

- Inspect materials and components before assembly: Check for any defects or damages that may affect quality.

- Use high-quality tools and equipment: Ensure precise measurements and secure fittings.

- Conduct thorough testing: Sit on the assembled seater to assess comfort, stability, and functionality.

- Seek feedback from quality control personnel: Request inspections and evaluations to verify adherence to standards.

9. Explain how you prioritize tasks and manage multiple projects simultaneously.

- Establish clear priorities: Identify the most important tasks based on deadlines, urgency, and impact.

- Create a work schedule: Plan a realistic timeline for completing tasks and allocate time accordingly.

- Delegate tasks effectively: Assign responsibilities to team members based on their skills and availability.

- Break down large projects: Divide complex projects into smaller, manageable chunks to avoid feeling overwhelmed.

- Use project management tools: Utilize software or apps to track progress, set reminders, and collaborate with others.

10. Describe a situation where you identified a problem in the assembly process and implemented a solution.

In a previous role, I encountered an issue where seat cushions were not fitting properly during assembly. After thorough inspection, I realized that the cushion dimensions did not align with the frame specifications. I immediately notified the quality control team and worked closely with them to identify the root cause.

To resolve the problem, I proposed modifying the assembly process slightly. By adjusting the placement of the cushions and using additional support material, we were able to ensure a snug and secure fit. This not only improved the overall quality of the seaters but also reduced production time by eliminating the need for rework.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seater Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seater Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Seater Assembler is responsible for manufacturing and assembling seats for various applications, including automobiles, airplanes, and furniture. They work with a variety of materials, including fabrics, leather, and metal, and use specialized tools and equipment to complete their tasks.

1. Assemble and install seat components

Seater Assemblers are responsible for assembling and installing all of the components of a seat, including the frame, cushions, upholstery, and hardware. They must follow precise instructions and specifications to ensure that the seat is assembled correctly and meets all safety standards.

- Locate and identify the correct components for each seat.

- Assemble the seat frame and attach the cushions.

- Install the upholstery and trim.

- Inspect the finished seat to ensure that it meets all quality standards.

2. Operate and maintain equipment

Seater Assemblers use a variety of specialized tools and equipment to complete their tasks. They must be able to operate and maintain this equipment safely and efficiently.

- Operate sewing machines, staplers, and other assembly tools.

- Maintain and clean equipment regularly.

- Identify and troubleshoot any problems with equipment.

3. Work with a team

Seater Assemblers typically work as part of a team. They must be able to communicate effectively with their team members and work together to complete tasks efficiently.

- Work with other assemblers to assemble and install seats.

- Communicate with supervisors and other team members to resolve problems.

- Maintain a clean and organized work area.

4. Meet production goals

Seater Assemblers are responsible for meeting production goals. They must be able to work quickly and efficiently to produce high-quality seats.

- Meet daily and weekly production goals.

- Identify and resolve any bottlenecks in the production process.

- Continuously improve their work methods to increase efficiency.

Interview Tips

Preparing for an interview can be daunting, but there are several things you can do to increase your chances of success.

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. You can also learn more about the specific responsibilities of the position and what the company is looking for in a candidate.

- Visit the company’s website.

- Read articles and news about the company.

- Talk to people who work for the company.

- Review the job description carefully.

- Identify your skills and experiences that are most relevant to the position.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice answering these questions ahead of time so that you can feel confident and prepared during your interview.

Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Why should we hire you?

- What are your salary expectations?

3. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the position and the company. It is also a good way to show the interviewer that you are interested in the position and that you have taken the time to prepare for the interview.

- Ask questions about the company’s culture and values.

- Ask questions about the specific responsibilities of the position.

- Ask questions about the company’s growth plans.

- Ask questions about the interviewer’s experience with the company.

4. Dress professionally and arrive on time

First impressions matter. When you go for an interview, it is important to dress professionally and arrive on time. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress in a suit or business casual attire.

- Be punctual for your interview.

- Be polite and respectful to everyone you meet.

5. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Be honest and authentic in your answers.

- Be confident in your abilities and experience.

- Be enthusiastic about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Seater Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!