Feeling lost in a sea of interview questions? Landed that dream interview for Second Class Welder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Second Class Welder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

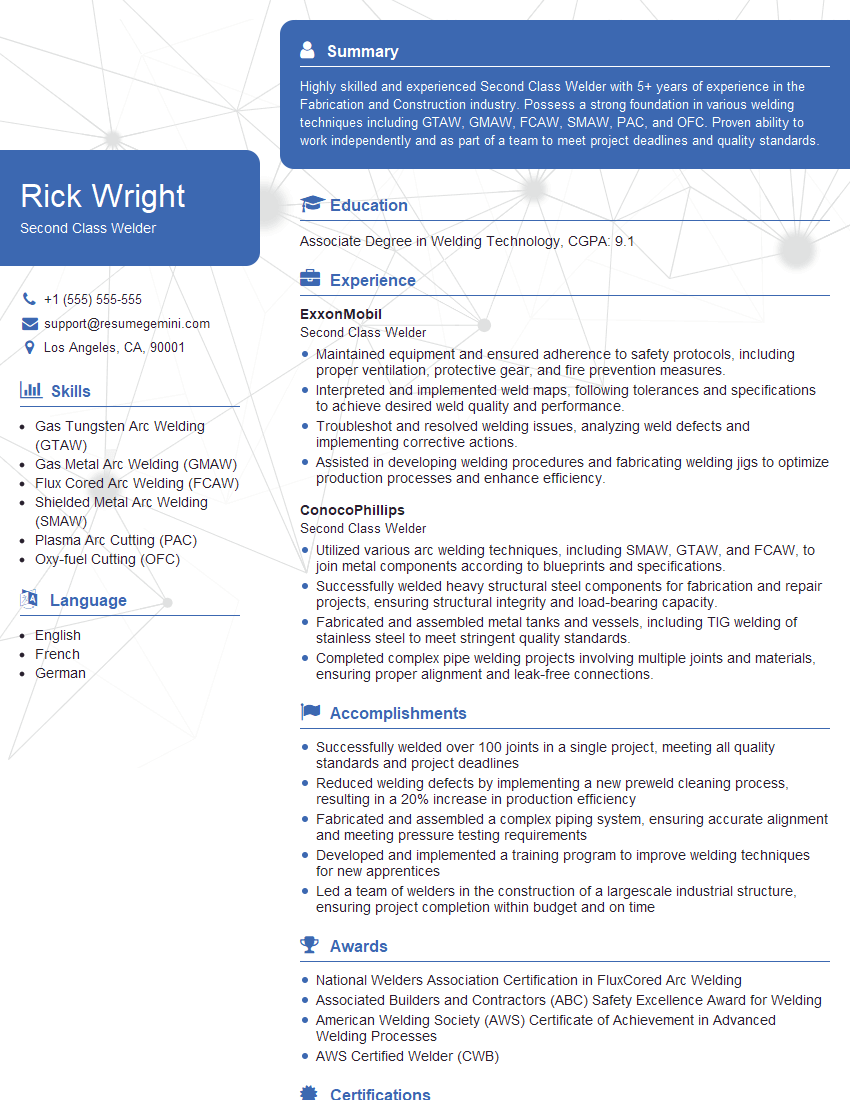

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Second Class Welder

1. What are the different types of welding processes that you are familiar with?

I am familiar with various welding processes, including:

- Shielded Metal Arc Welding (SMAW) or Stick Welding

- Gas Tungsten Arc Welding (GTAW) or TIG Welding

- Gas Metal Arc Welding (GMAW) or MIG Welding

- Flux-Cored Arc Welding (FCAW)

- Submerged Arc Welding (SAW)

2. What is the difference between preheating and postheating in welding?

Preheating

- Heating the metal before welding to reduce the risk of cracking

- Improves the weldability of certain metals

Postheating

- Heating the weld after welding to relieve residual stresses

- Improves the toughness and ductility of the weld

3. What are the factors that affect the quality of a weld?

The quality of a weld is influenced by several factors, including:

- Welding process

- Welding parameters (e.g., amperage, voltage, travel speed)

- Joint design

- Material thickness

- Welding consumables

- Welder’s skill and experience

4. What are the common welding defects and how can they be prevented?

Some common welding defects include:

- Cracking: Prevent by using proper preheating, postheating, and welding techniques

- Porosity: Prevent by cleaning the weld area, using dry welding consumables, and shielding the weld from the atmosphere

- Undercut: Prevent by using the correct welding parameters and techniques

- Cold lap: Prevent by ensuring proper joint fit-up and using the correct welding parameters

- Slag inclusions: Prevent by using proper welding techniques and cleaning the weld area

5. What are the safety precautions that should be observed when welding?

When welding, it is crucial to adhere to safety precautions, such as:

- Wearing appropriate protective gear (e.g., helmet, gloves, apron)

- Ensuring proper ventilation to avoid inhaling harmful fumes

- Handling and storing welding equipment safely

- Inspecting equipment regularly and maintaining it in good condition

- Following proper fire safety practices

6. What is the importance of weld inspection?

Weld inspection is crucial for ensuring the integrity and quality of welded joints. It helps to:

- Identify and correct any defects or inconsistencies

- Verify that the weld meets the required specifications and standards

- Ensure the safety and reliability of the welded structure

- Document the condition of the weld for future reference

7. What are the different methods of weld inspection?

Weld inspection methods include:

- Visual inspection

- Non-destructive testing (e.g., ultrasonic testing, radiographic testing)

- Destructive testing (e.g., tensile testing, bend testing)

8. What is your experience with welding different types of materials?

I have experience welding various materials, including:

- Mild steel

- Stainless steel

- Aluminum

- Cast iron

- Copper and its alloys

9. What is the most challenging welding project you have worked on?

The most challenging welding project I have worked on was [Describe the project].

- Explain the complexities and challenges involved

- Describe how you overcame those challenges and the techniques you employed

- Highlight any special skills or knowledge you gained from the experience

10. What are your career goals as a welder?

My career goals as a welder are:

- To become a highly skilled and experienced welder

- To work on challenging and rewarding welding projects

- To contribute to the success of my team and organization

- To stay updated on the latest welding technologies and best practices

- To advance my career through training and certification

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Second Class Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Second Class Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Second Class Welders are highly skilled professionals who play a crucial role in various industries, including construction, manufacturing, and shipbuilding. Their primary responsibility is to join metal components using welding techniques, ensuring the structural integrity and safety of the finished product.

1. Welding Techniques

Second Class Welders must be proficient in various welding techniques, including:

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Flux-Cored Arc Welding (FCAW)

2. Weld Inspection

After welding, Second Class Welders are responsible for inspecting their work to ensure it meets the required standards and specifications. This involves:

- Visual inspection

- Non-destructive testing (NDT) methods

3. Equipment Maintenance

Second Class Welders must maintain their welding equipment in good working condition, including:

- Welding machines

- Power sources

- Hand tools

4. Safety Compliance

Welding involves hazardous materials and processes, so Second Class Welders must adhere to strict safety protocols, including:

- Wearing appropriate personal protective equipment (PPE)

- Following proper welding procedures

Interview Tips

Preparing for a Second Class Welder interview requires a combination of technical knowledge, soft skills, and interview strategies.

1. Technical Proficiency

Highlight your proficiency in various welding techniques, especially those relevant to the job description. Be prepared to discuss your experience and skills in welding different materials and thicknesses.

- Example: “I have extensive experience in SMAW and GMAW, and I’m proficient in welding both ferrous and non-ferrous metals.”

2. Problem-Solving Skills

Welders often encounter unexpected challenges on the job. Emphasize your problem-solving abilities and give examples of how you have overcome welding-related issues.

- Example: “In a previous project, I encountered a problem with weld porosity. I analyzed the situation, adjusted my welding parameters, and successfully resolved the issue.”

3. Attention to Detail

Welding requires meticulous attention to detail. Highlight your ability to follow instructions precisely and complete welds that meet the required specifications.

- Example: “I have a strong eye for detail and always take the time to ensure my welds meet or exceed the required standards.”

4. Safety Consciousness

Emphasize your commitment to safety and your understanding of welding-related hazards. Discuss your experience in complying with safety protocols and using personal protective equipment.

- Example: “I believe that safety is paramount in welding, and I always follow proper procedures to protect myself and others.”

Next Step:

Now that you’re armed with the knowledge of Second Class Welder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Second Class Welder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini