Feeling lost in a sea of interview questions? Landed that dream interview for Section Leader and Machine Setter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Section Leader and Machine Setter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

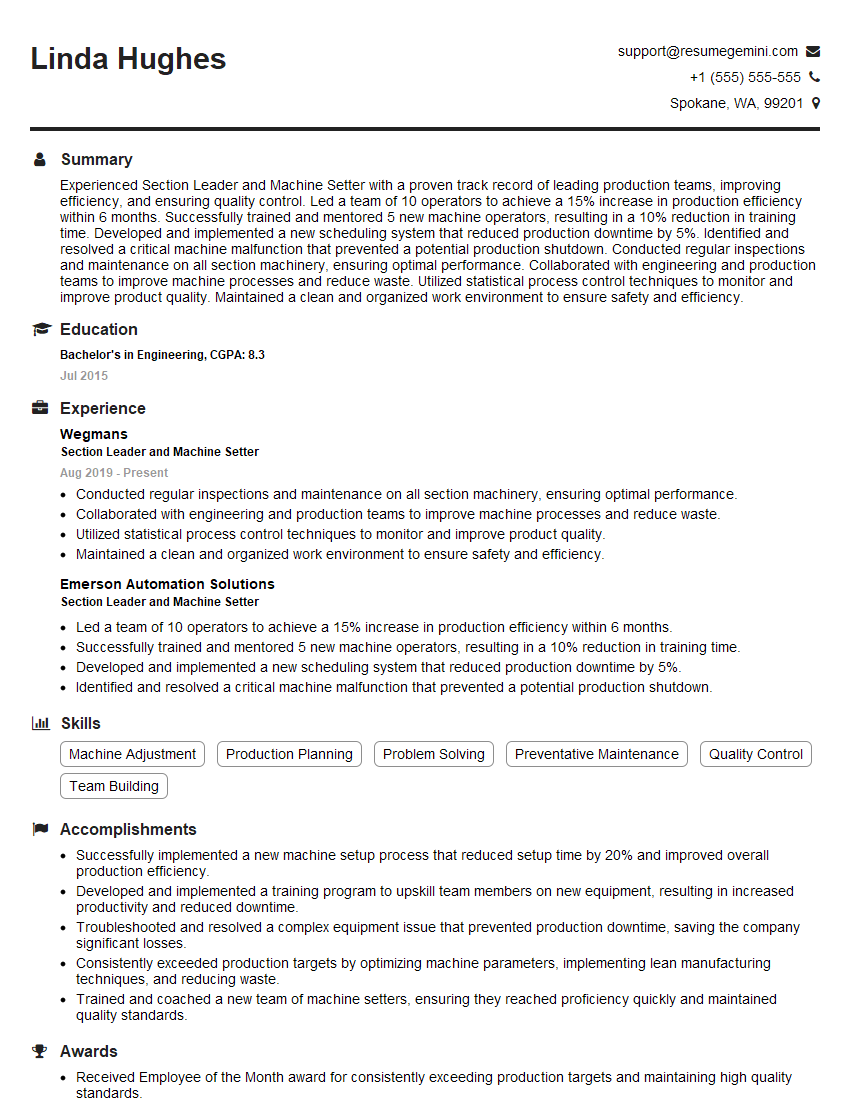

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Section Leader and Machine Setter

1. What is the role of a Section Leader in a manufacturing environment?

As a Section Leader, my primary responsibilities involve managing and overseeing a specific section or department within the manufacturing facility. I am accountable for:

- Leading and motivating a team of operators and technicians to achieve production goals and quality standards.

- Planning and scheduling production activities, ensuring efficient workflow and adherence to deadlines.

- Monitoring production processes to identify and resolve bottlenecks and improve productivity.

- Implementing and maintaining safety protocols and ensuring compliance with regulatory requirements.

- Troubleshooting technical issues and coordinating with maintenance personnel for equipment repairs.

- Providing training and development opportunities to team members to enhance their skills and knowledge.

- Collaborating with other departments and management to optimize overall production processes.

2. What are the key performance indicators (KPIs) that you track as a Section Leader?

Production Output

- Units produced per hour or shift

- Overall equipment effectiveness (OEE)

- Production yield and scrap rates

Quality Control

- Number of defects per unit

- Customer satisfaction and complaint rates

- Adherence to quality standards and specifications

Team Performance

- Attendance and punctuality rates

- Training completion and skill development

- Employee engagement and morale

Cost Management

- Material and labor costs

- Equipment maintenance and downtime expenses

- Continuous improvement initiatives to reduce costs

3. Describe the steps involved in setting up a new machine for production.

Setting up a new machine for production involves the following steps:

- Reviewing machine specifications and understanding its capabilities.

- Preparing the machine by installing it in the designated location and connecting utilities.

- Calibrating the machine according to manufacturer’s instructions and company standards.

- Loading the necessary tooling, fixtures, and materials into the machine.

- Configuring the machine’s parameters and settings to meet production requirements.

- Running test cycles to ensure proper operation and accuracy.

- Documenting the setup process and machine parameters for future reference.

- Training operators on how to operate and maintain the machine.

4. How do you ensure that machines are maintained properly to minimize downtime?

To minimize machine downtime and ensure proper maintenance, I follow these key practices:

- Establish a regular maintenance schedule based on manufacturer’s recommendations and usage patterns.

- Conduct daily inspections to identify potential issues and address them promptly.

- Lubricate and clean machines regularly to prevent wear and tear.

- Monitor machine performance data to detect any anomalies or early signs of problems.

- Train operators to perform basic maintenance tasks and report any unusual observations.

- Maintain a spare parts inventory to minimize delays in case of breakdowns.

- Collaborate with maintenance personnel to address complex issues and ensure timely repairs.

- Implement preventive maintenance strategies, such as predictive analytics and condition monitoring, to anticipate and mitigate potential failures.

5. What are some common challenges faced by Machine Setters and how do you overcome them?

Common challenges faced by Machine Setters include:

- Equipment breakdowns and malfunctions

- Quality issues and non-conforming products

- Tight production schedules and deadlines

- Lack of skilled labor and training opportunities

- Safety hazards and compliance concerns

To overcome these challenges, I:

- Prioritize regular maintenance and preventive measures to minimize equipment downtime.

- Implement stringent quality control measures and train operators on inspection techniques.

- Work closely with production planning to manage schedules and adjust them as needed.

- Identify training needs and collaborate with management to provide opportunities for skill development.

- Conduct thorough risk assessments and implement safety protocols to ensure a safe work environment.

6. How do you stay up-to-date on the latest manufacturing technologies and best practices?

To stay current with industry advancements, I actively engage in the following activities:

- Attend industry conferences, seminars, and workshops.

- Read technical journals and publications.

- Network with colleagues and experts in the field.

- Explore online resources and webinars.

- Collaborate with vendors and equipment manufacturers to learn about emerging technologies.

7. How do you handle conflicts or disagreements within your team?

When conflicts or disagreements arise within my team, I approach them in a professional and constructive manner:

- Create a safe and open environment where team members feel comfortable expressing their views.

- Listen actively to all perspectives and try to understand the underlying reasons for the conflict.

- Facilitate discussions and encourage respectful communication.

- Identify common ground and areas of agreement.

- Work collaboratively to develop solutions that address the concerns of all parties involved.

- Document agreements and follow up to ensure that resolutions are implemented.

8. What are your strengths and weaknesses as a Section Leader?

Strengths

- Strong leadership skills and ability to motivate and inspire teams

- Excellent problem-solving and decision-making abilities

- Deep understanding of manufacturing processes and best practices

- Proven track record of improving productivity and reducing costs

- Excellent communication and interpersonal skills

Weaknesses

- Can be overly detail-oriented at times

- May have difficulty delegating tasks

- Still developing my knowledge in specific areas of manufacturing technology

9. What are your career goals and aspirations?

My career goals include:

- Continuing to grow and develop as a leader in manufacturing.

- Taking on more responsibilities and managing larger teams.

- Implementing innovative technologies and processes to improve operational efficiency.

- Mentoring and training future leaders in the industry.

10. Why are you interested in this position at our company?

I am highly interested in this position at your esteemed company for several reasons:

- Your company’s reputation for excellence in manufacturing and commitment to innovation aligns with my own values and aspirations.

- The scope of responsibilities outlined in this role matches my skills and experience, providing me with the opportunity to make significant contributions.

- I am eager to collaborate with a team of experienced professionals and learn from industry leaders.

- I believe that my expertise and dedication can add value to your organization and help drive continued success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Section Leader and Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Section Leader and Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Section Leader and Machine Setter plays a pivotal role in overseeing production operations, ensuring machine efficiency, and maintaining high-quality standards.

1. Production Management

Supervises production activities within a specific section or area.

- Manages work schedules and allocates tasks to team members.

- Monitors production progress and makes necessary adjustments to meet deadlines.

2. Machine Setting and Maintenance

Sets up, calibrates, and maintains machinery according to specifications.

- Troubleshoots and resolves machine malfunctions promptly.

- Performs regular maintenance tasks to ensure optimal machine performance.

- Monitors machine metrics and identifies potential issues.

3. Quality Control

Ensures adherence to quality standards and identifies areas for improvement.

- Conducts inspections and verifies product quality.

- Implements quality control measures and corrective actions.

- Provides feedback and training to team members on quality-related matters.

4. Team Management

Supervises and motivates a team of operators and assistants.

- Provides guidance and support to team members.

- Conducts performance evaluations and provides constructive feedback.

- Recognizes and rewards employee achievements.

5. Continuous Improvement

Contributes to process improvement initiatives and seeks ways to enhance efficiency.

- Identifies production bottlenecks and develops solutions.

- Implements new technologies and best practices to improve operations.

- Shares ideas and knowledge with colleagues.

Interview Tips

Preparing for an interview for the Section Leader and Machine Setter position requires careful planning and attention to detail.

1. Research the Company and Position

Thoroughly research the company, its products, and the specific job responsibilities.

- Visit the company website, read industry news, and connect with employees on LinkedIn.

- Learn about the company’s culture, values, and growth trajectory.

- Identify the key skills and qualifications required for the role.

2. Practice Your Answers to Common Interview Questions

Prepare well-structured responses to common interview questions.

- Describe your experience in production management and machine setting.

- Tell me about a time you successfully resolved a complex machine problem.

- How do you ensure that your team consistently meets quality standards?

- What are your strengths and weaknesses as a leader?

3. Highlight Your Skills and Experience

- Quantify your accomplishments whenever possible.

- Use action verbs and provide specific examples to demonstrate your abilities.

- Tailor your resume and cover letter to the specific job description.

Emphasize your relevant skills and experience in your resume and cover letter.

4. Ask Thoughtful Questions

Asking intelligent questions during the interview shows interest and engagement.

- Inquire about the company’s growth plans and industry outlook.

- Ask about opportunities for career advancement within the organization.

- Seek clarification on any aspect of the job that you find unclear.

Next Step:

Now that you’re armed with the knowledge of Section Leader and Machine Setter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Section Leader and Machine Setter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini