Are you gearing up for an interview for a Section Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Section Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

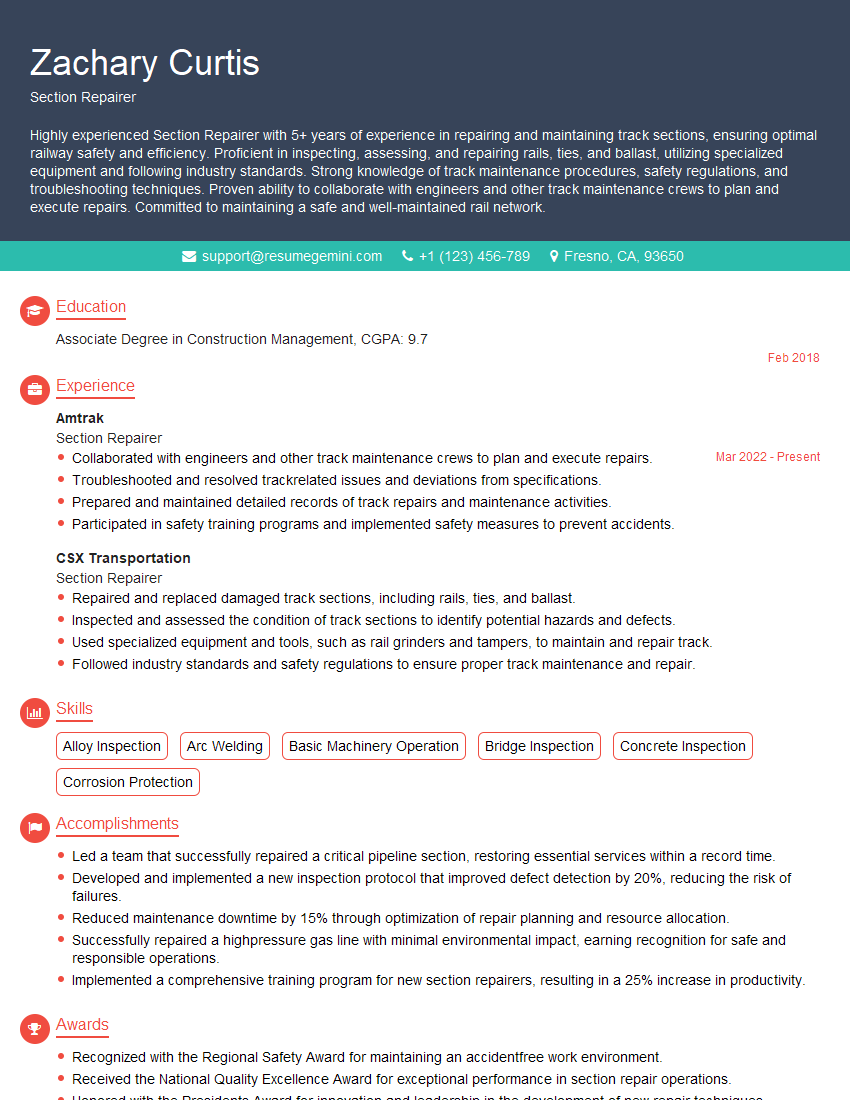

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Section Repairer

1. Could you please describe the procedure of repairing a damaged section of a pipeline?

Sure, here’s the general procedure for repairing a damaged section of a pipeline:

- Identify and isolate the damaged section.

- Excavate the damaged section and remove it.

- Prepare the ends of the pipe for welding.

- Weld in a new section of pipe.

- Pressure test the repaired section.

- Backfill the excavation and restore the area.

2. What are the different types of pipeline defects and how do you detect them?

There are several types of pipeline defects, including:

Corrosion

- Internal corrosion is caused by the chemical reaction between the pipeline and the fluid flowing through it.

- External corrosion is caused by the chemical reaction between the pipeline and the soil or water surrounding it.

Cracks

- Cracks can be caused by a variety of factors, including stress, fatigue, and corrosion.

- Cracks can be detected using a variety of methods, including visual inspection, ultrasonic testing, and radiography.

Dents

- Dents are caused by the impact of an object on the pipeline.

- Dents can be detected using a variety of methods, including visual inspection, magnetic particle inspection, and ultrasonic testing.

3. How do you ensure the safety of yourself and others while working on a pipeline repair?

Safety is paramount when working on a pipeline repair. Here are some steps I take to ensure the safety of myself and others:

- Follow all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE).

- Use proper tools and equipment.

- Be aware of the hazards associated with the work.

- Work with a qualified team.

4. What are the challenges of working as a Section Repairer?

Some challenges of working as a Section Repairer include:

- Working in all weather conditions.

- Working in confined spaces.

- Working with hazardous materials.

- Being on call 24/7.

5. What is your experience with using specialized equipment for pipeline repair?

I have experience using a variety of specialized equipment for pipeline repair, including:

- Pipeline cutting and welding equipment

- Excavation equipment

- Non-destructive testing equipment

- Pressure testing equipment

6. How do you stay up-to-date on the latest pipeline repair techniques?

I stay up-to-date on the latest pipeline repair techniques by:

- Attending industry conferences and workshops

- Reading trade publications

- Taking online courses

- Networking with other pipeline repair professionals

7. What are some of the common mistakes that you see made by less experienced Section Repairers?

Some of the common mistakes that I see made by less experienced Section Repairers include:

- Not following safety procedures

- Using the wrong tools or equipment

- Not properly preparing the pipe for welding

- Not pressure testing the repaired section

8. How do you prioritize your work when you have multiple projects to complete?

When I have multiple projects to complete, I prioritize my work based on the following factors:

- The importance of the project

- The deadline for the project

- The resources available to me

- The potential impact of the project

9. How do you handle working under pressure?

I handle working under pressure by:

- Staying calm and focused

- Prioritizing my work

- Delegating tasks to others when necessary

- Taking breaks when needed

10. What are your career goals?

My career goals are to:

- Become a certified pipeline repair technician

- Work on more complex and challenging pipeline repair projects

- Eventually become a supervisor or manager of a pipeline repair crew

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Section Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Section Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Inspecting and Assessing Damage

Thoroughly inspect damaged sections of the vessel to determine the extent of repair required.

- Identify the type of damage, such as corrosion, structural cracks, or collision damage.

- Assess the severity of the damage and prioritize repairs based on urgency.

2. Repairing and Fabricating

Execute repairs and fabrications in line with established standards and specifications:

- Weld, cut, grind, and shape metal components using appropriate tools and techniques.

- Fabricate new sections or replace damaged ones using various materials, including steel, aluminum, and fiberglass.

3. Installing and Assembling

Install and assemble repaired or new sections onto the vessel:

- Position components accurately and securely using lifting equipment and tools.

- Align and fasten components using bolts, rivets, or welding techniques.

4. Testing and Inspection

Conduct thorough testing and inspection to ensure the quality of repairs:

- Perform non-destructive tests, such as ultrasonic testing or radiography, to inspect welds and identify any defects.

- Conduct pressure tests or load testing to verify the integrity and functionality of repaired sections.

5. Maintaining Equipment and Tools

Maintain and regularly inspect equipment and tools to ensure optimal performance:

- Clean and lubricate tools and machinery to prevent breakdowns and extend their lifespan.

- Identify and report any maintenance or repair needs promptly.

Interview Tips

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and recent developments in the shipbuilding and repair industry.

- Visit the company website, read industry publications, and engage in online forums.

- Learn about the specific types of vessels or projects the company specializes in.

2. Showcase Technical Expertise and Experience

Highlight your technical skills and experience relevant to the job responsibilities. Use specific examples to demonstrate your proficiency.

- Provide instances where you successfully repaired complex damage, fabricated new sections, or conducted thorough inspections.

- Quantify your accomplishments whenever possible, such as time saved or cost reductions due to efficient repairs.

3. Emphasize Safety and Quality

Consistently emphasize your commitment to safety and quality in all aspects of your work.

- Share examples of your adherence to safety protocols and industry best practices.

- Describe your attention to detail and thorough approach to ensuring the quality of your repairs.

4. Demonstrate Teamwork and Communication

Highlight your ability to work effectively in a team environment and communicate clearly with colleagues.

- Describe situations where you successfully collaborated with others to complete complex repairs on schedule.

- Provide examples of how you effectively communicate technical information to non-technical team members.

5. Prepare Questions to Ask

Preparing thoughtful questions to ask the interviewer demonstrates your interest in the company and the role.

- Ask about the company’s current projects and future growth plans.

- Inquire about the team structure and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Section Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!