Are you gearing up for a career in Sectional Belt-Mold Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Sectional Belt-Mold Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

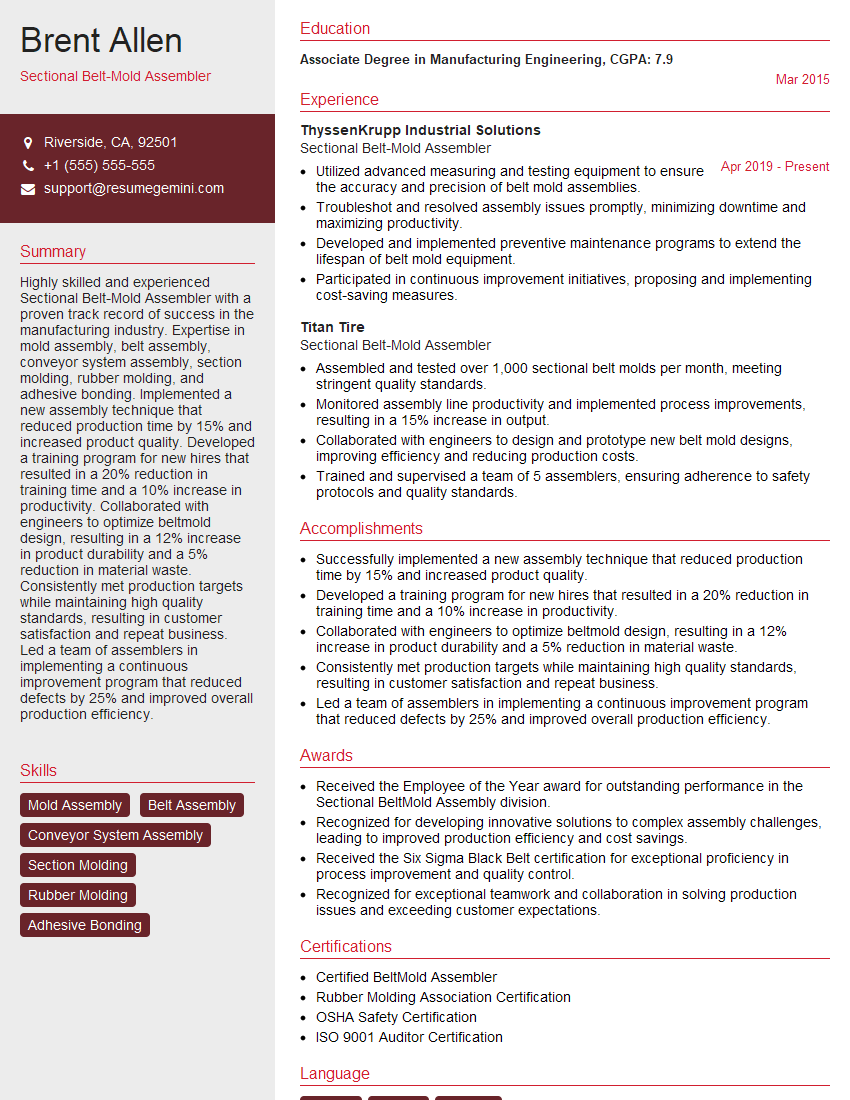

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sectional Belt-Mold Assembler

1. How do you ensure the proper alignment of molds during assembly?

To ensure proper alignment of molds during assembly, I follow these steps:

- Inspect the molds for any defects or damage.

- Use alignment pins or fixtures to guide mold placement.

- Check the alignment using a straightedge or laser level.

- Make adjustments as necessary to achieve precise alignment.

2. What techniques do you use to minimize belt tension and prevent belt slippage?

Adjusting Tension

- Use tensioning devices such as idlers or tensioner pulleys.

- Monitor belt tension using a tension gauge or tachometer.

- Follow manufacturer’s recommendations for optimal tension levels.

Preventing Slippage

- Select belts with appropriate friction characteristics.

- Use pulleys with the correct groove profile and diameter.

- Ensure pulleys and belts are free of debris or contamination.

3. How do you troubleshoot and repair common belt-mold assembly issues?

When troubleshooting belt-mold assembly issues, I follow these steps:

- Identify the problem by observing the assembly and listening for unusual noises.

- Check for loose or misaligned components, worn belts, or damaged molds.

- Use appropriate tools, such as wrenches or screwdrivers, to make adjustments or repairs.

- Test the assembly after repairs to ensure proper operation.

4. What safety precautions do you follow when working with belt-mold assemblies?

I prioritize safety by adhering to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Ensuring the work area is well-lit and free of hazards.

- Inspecting equipment and machinery regularly and reporting any issues.

- Following lockout/tagout procedures to prevent accidental start-up.

5. How do you stay up-to-date on industry best practices and technological advancements in belt-mold assembly?

I stay updated by:

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Consulting with experts and professionals in the field.

- Participating in online forums and discussions.

6. What is the importance of maintaining proper belt tension in minimizing energy consumption?

Appropriate belt tension is crucial for energy efficiency because:

- It reduces friction between the belt and pulleys, lowering energy losses.

- It prevents belt slippage, which can waste energy and damage the belt.

- It ensures proper power transmission and prevents excessive wear on components.

7. What factors do you consider when selecting the right belt material for a specific application?

When choosing a belt material, I evaluate factors such as:

- Load capacity and tensile strength.

- Flexibility and resistance to abrasion.

- Environmental conditions, including temperature, moisture, and chemicals.

- Type and speed of operation.

8. How do you handle complex assemblies that require precision alignment of multiple components?

For complex assemblies, I:

- Use precision measuring tools, such as calipers and micrometers.

- Create detailed assembly plans and follow them meticulously.

- Work systematically and pay attention to detail.

- Perform regular inspections throughout the assembly process.

9. What are the potential causes of belt vibration and how do you address them?

Potential causes of belt vibration include:

- Misalignment of pulleys.

- Belt tension issues.

- Worn or damaged belts.

- Bearing problems.

To address these issues, I:

- Inspect the assembly and identify the source of vibration.

- Make necessary adjustments, such as aligning pulleys or tightening belts.

- Replace worn or damaged components.

10. How do you ensure that your assemblies meet the required specifications and quality standards?

I ensure quality by:

- Following established assembly procedures and using proper tools and equipment.

- Conducting rigorous inspections at each stage of the assembly process.

- Using calibrated measuring and testing equipment.

- Adhering to industry standards and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sectional Belt-Mold Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sectional Belt-Mold Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sectional Belt-Mold Assemblers are responsible for assembling and checking conveyor belt sections according to specifications, using hand and power tools.

1. Assemble belt sections

Assemble belt sections by joining individual components, such as fabric, rubber, and metal, using adhesives, bolts, or other fasteners.

- Follow blueprints and work orders to determine the correct components and assembly procedures.

- Use hand tools, such as wrenches, screwdrivers, and hammers, to assemble the belt sections.

2. Inspect belt sections

Inspect belt sections for defects, such as tears, cuts, or misalignments, using visual and tactile methods.

- Use measuring tools, such as rulers and calipers, to ensure that the belt sections meet specifications.

- Mark and repair any defects found during inspection.

3. Test belt sections

Test belt sections to ensure that they meet performance standards, such as strength, durability, and resistance to wear and tear.

- Use testing equipment, such as tensile testers and load cells, to evaluate the performance of the belt sections.

- Make adjustments to the belt sections as needed to meet performance requirements.

4. Maintain work area

Maintain a clean and organized work area to ensure safety and efficiency.

- Keep tools and materials organized and in their designated places.

- Dispose of waste materials and scrap properly.

Interview Tips

Preparing for an interview can be nerve-wracking, but with the right strategies, you can increase your chances of success.

1. Research the company and the position

Take the time to learn about the company’s values, culture, and recent news. This will help you understand the company’s goals and how you can contribute to them.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Practice your answers to common interview questions

There are certain questions that are commonly asked in interviews, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare your answers to these questions in advance so that you can deliver them confidently.

- Use the STAR method to answer behavioral questions (Situation, Task, Action, Result).

- Tailor your answers to the specific job description and company.

3. Be prepared to talk about your skills and experience

The interviewer will want to know what you can bring to the table. Be prepared to discuss your skills, experience, and accomplishments in detail.

- Quantify your accomplishments whenever possible.

- Use specific examples to illustrate your skills and experience.

4. Ask questions

Asking questions shows that you are engaged in the conversation and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Prepare a list of questions to ask the interviewer.

- Ask questions that are relevant to the position and the company.

5. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for the job.

- Arrive for your interview a few minutes early.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sectional Belt-Mold Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!