Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Seed Cleaner Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

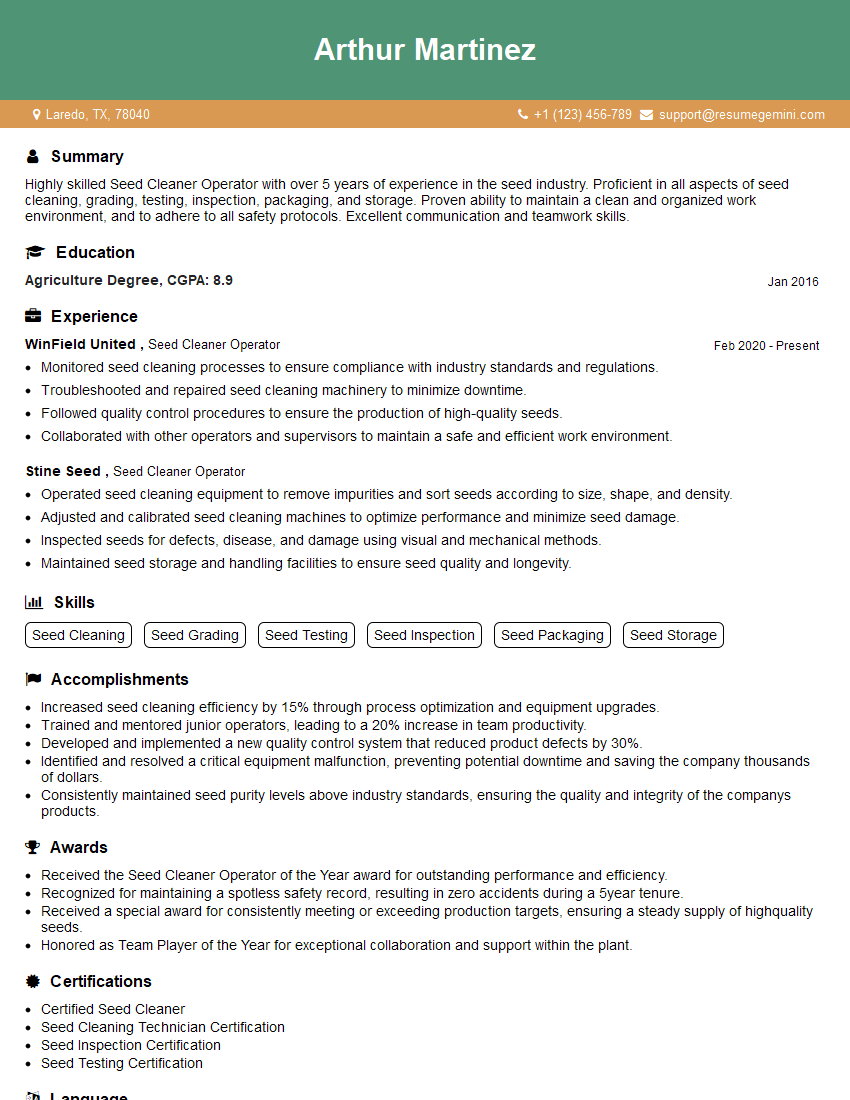

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seed Cleaner Operator

1. Describe your experience in operating different types of seed cleaning equipment?

In my previous role as a Seed Cleaner Operator, I gained hands-on experience operating various seed cleaning equipment, including:

- Gravity separators

- Screen cleaners

- Aspirators

- Magnetic separators

- Seed treaters

2. Explain the process of seed cleaning and grading, including the different steps involved?

Understanding the Seed

- Identifying the crop and variety

- Examining the seed’s physical characteristics

Pre-Cleaning

- Removing large debris and foreign materials

- Scalping to separate seeds by size

Cleaning

- Using gravity separators to remove heavier impurities

- Employing screen cleaners to separate seeds by size and shape

Grading

- Utilizing aspirators to remove light materials

- Separating seeds by density using magnetic separators

- Applying seed treaters to protect seeds from pests and diseases

3. What are the different types of impurities commonly found in seed, and how are they removed?

Impurities found in seed include:

- Rocks and soil: Removed using gravity separators

- Weed seeds: Separated by size using screen cleaners

- Chaff: Removed using aspirators

- Insects and eggs: Eliminated using magnetic separators

- Diseased seeds: Detected and removed during visual inspection

4. What quality control measures do you follow to ensure the accuracy and reliability of seed cleaning processes?

I implement the following quality control measures:

- Regular calibration and maintenance of equipment

- Monitoring seed flow and making adjustments as needed

- Conducting visual inspections of the cleaned seed

- Sampling and testing the seed to verify purity and germination rates

- Maintaining detailed records of all cleaning processes

5. What are the safety protocols you adhere to when operating seed cleaning equipment?

- Wearing appropriate safety gear, including gloves, safety glasses, and a respirator

- Following lockout/tagout procedures before servicing equipment

- Keeping work areas clean and free of tripping hazards

- Being aware of potential hazards, such as dust explosions

- Reporting any accidents or near misses promptly

6. How do you troubleshoot common issues encountered in seed cleaning operations?

- Clogged screens: Cleaning or replacing screens

- Insufficient aspiration: Adjusting air flow or cleaning ducts

- Seed damage: Verifying equipment settings and calibrations

- Impurities not removed: Identifying the type of impurity and adjusting cleaning methods accordingly

- Low seed yield: Optimizing cleaning parameters and inspecting equipment for wear and tear

7. Describe your approach to maintaining a clean and organized work environment?

I maintain a clean work environment by:

- Regularly sweeping and cleaning floors

- Storing materials and equipment properly

- Disposing of waste and debris promptly

- Following established cleaning protocols

- Encouraging a culture of cleanliness and organization among colleagues

8. Can you explain the importance of seed cleaning in the agricultural industry?

Seed cleaning is crucial in the agricultural industry because it provides the following benefits:

- Improved seed quality and germination rates

- Reduced disease and pest transmission

- Increased crop yields and profitability

- Complies with industry standards and regulations

- Contributes to sustainable agricultural practices

9. What are the latest advancements in seed cleaning technology that you are familiar with?

- Optical sorters: Utilizing cameras and sensors to identify and remove foreign materials

- Precision air classification: Separating seeds based on their aerodynamic properties

- Automated quality control systems: Monitoring and adjusting cleaning processes in real-time

- Seed enhancements: Applying treatments to improve seed performance and longevity

- Robotics and AI: Streamlining seed handling and improving efficiency

10. How do you stay up to date with the latest industry best practices in seed cleaning?

- Attending industry conferences and workshops

- Subscribing to trade publications and online resources

- Consulting with experts and researchers in the field

- Participating in online forums and discussion groups

- Continuously seeking opportunities for professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seed Cleaner Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seed Cleaner Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Seed Cleaner Operators are responsible for the proper and efficient operation of seed cleaning equipment to ensure the production of high-quality, cleaned seeds. Their primary duties include:

1. Equipment Operation and Maintenance

Operating and controlling seed cleaning machinery, including screens, air separators, and gravity tables

- Monitoring and adjusting equipment settings to achieve optimal seed cleaning results

- Performing routine maintenance and minor repairs on seed cleaning equipment

2. Quality Control and Inspection

Inspecting and evaluating the quality of cleaned seeds, including purity, germination percentage, and moisture content

- Taking samples and conducting quality control tests to ensure seeds meet specified standards

- Rejecting batches of seeds that do not meet quality requirements

3. Material Handling

Loading and unloading seed materials from storage bins, conveyors, and other equipment

- Ensuring proper storage and handling techniques to prevent damage or contamination of seeds

- Cleaning and disinfecting equipment and work areas to maintain hygiene and prevent cross-contamination

4. Record Keeping and Documentation

Maintaining accurate records of seed cleaning operations, including equipment settings, quality control results, and production data

- Preparing reports and providing updates on seed cleaning performance to supervisors

- Adhering to company policies and procedures regarding record keeping and documentation

Interview Tips

To prepare for a Seed Cleaner Operator interview, candidates should:

1. Research the Company and Industry

Familiarize themselves with the seed cleaning company, its products, and the industry they operate in

- Research the company’s website, social media, and industry publications

- Attend industry events or conferences to network and gather insights

2. Highlight Relevant Experience and Skills

Emphasize previous experience in operating and maintaining seed cleaning equipment, as well as knowledge of seed quality standards

- Provide specific examples of successful seed cleaning operations and quality control measures implemented

- Showcase technical skills, such as troubleshooting equipment issues and optimizing cleaning processes

3. Demonstrate Attention to Detail and Accuracy

Convey a strong work ethic and an ability to pay close attention to details, as accuracy is crucial in seed cleaning

- Describe instances where they maintained meticulous records and ensured the accuracy of their work

- Emphasize their ability to follow written instructions and adhere to quality control protocols

4. Prepare for Common Interview Questions

Anticipate and prepare answers to common interview questions related to seed cleaning, equipment operation, and quality control

- Example: “Describe your experience in operating seed cleaning equipment.”

- Example: “How do you ensure the quality of cleaned seeds meets industry standards?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Seed Cleaner Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.