Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Seed Cutter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Seed Cutter so you can tailor your answers to impress potential employers.

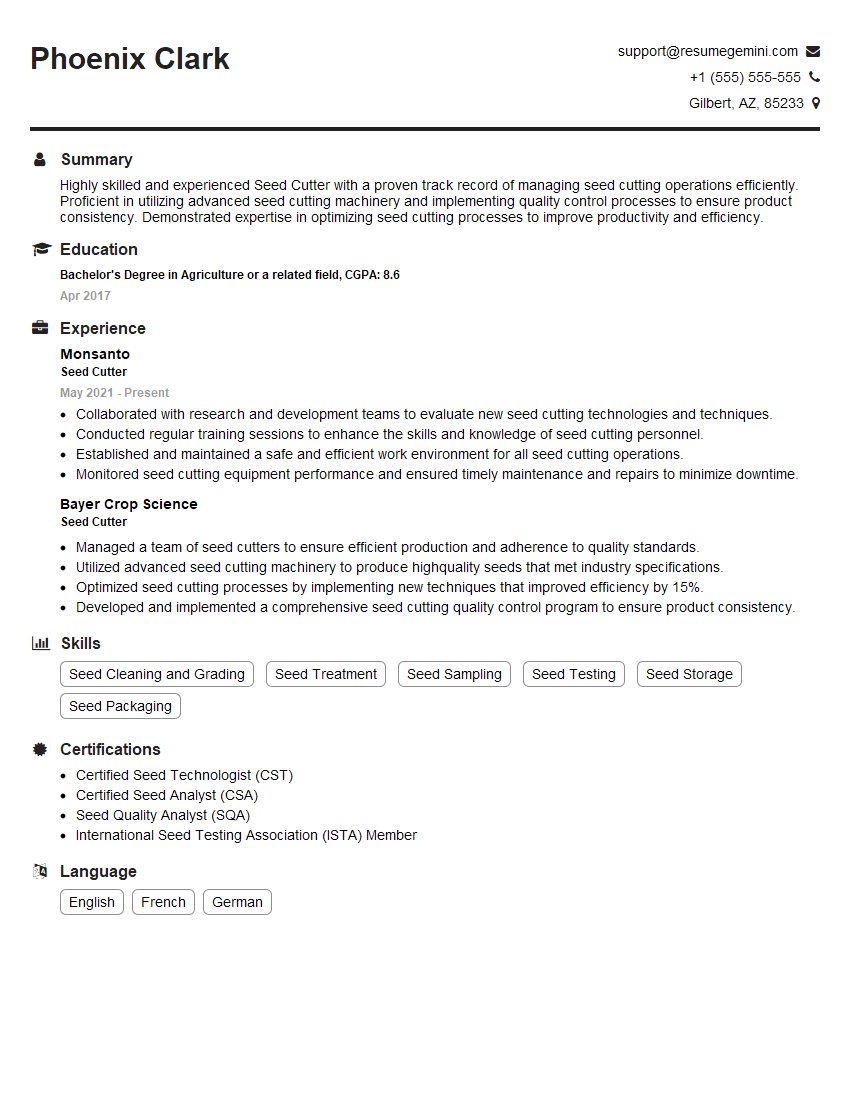

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seed Cutter

1. How do you ensure the accuracy and precision of seed cutting processes?

To ensure the accuracy and precision of seed cutting processes, I employ the following techniques:

- Calibration and maintenance of equipment: I regularly calibrate and maintain all cutting equipment, including seed cutters, sharpeners, and conveyors, to ensure they meet precision standards.

- Use of high-quality cutting blades: I select and use high-quality cutting blades that are designed for precise cuts and prevent seed damage.

- Visual inspection: I conduct thorough visual inspections of cut seeds to identify any defects or inconsistencies and make necessary adjustments.

- Adherence to cutting specifications: I strictly adhere to established cutting specifications, ensuring that seeds are cut to the correct size, shape, and depth.

- Quality control measures: I implement quality control measures throughout the cutting process, including sampling and testing, to verify accuracy and precision.

2. What techniques do you use to minimize seed damage during the cutting process?

Prevention of blade overheating

- Use of sharp blades to prevent tearing and crushing

- Adequate cooling systems to prevent excessive heat build-up

Seed handling techniques

- Gentle handling to avoid bruising or damage

- Proper seed preparation and conditioning to enhance cut quality

Cutting environment optimization

- Controlled humidity and temperature to prevent seed dehydration or damage

- Vibration reduction to minimize seed agitation and potential damage

3. How do you handle different seed types with varying hardness and moisture content?

To handle different seed types with varying hardness and moisture content, I employ the following strategies:

- Adjusting cutting parameters: I adjust cutting parameters such as blade speed, feed rate, and depth to accommodate different seed characteristics.

- Selection of appropriate cutting blades: I use specialized cutting blades designed for specific seed types and hardness levels.

- Moisture conditioning: I pre-condition seeds with varying moisture content to achieve optimal cutting conditions.

- Customized cutting processes: I develop customized cutting processes for different seed types, considering their unique properties.

4. What troubleshooting techniques do you employ when encountering seed cutting issues?

When encountering seed cutting issues, I utilize the following troubleshooting techniques:

- Equipment inspection: I thoroughly inspect cutting equipment, including blades, conveyors, and sensors, to identify any malfunctions or damage.

- Review of cutting parameters: I check and adjust cutting parameters such as blade speed, feed rate, and depth to optimize the cutting process.

- Seed analysis: I examine cut seeds to identify any defects or inconsistencies that may indicate underlying issues.

- Consultation with experts: I consult with experienced colleagues or technical specialists to seek guidance and support in resolving complex problems.

5. How do you maintain and calibrate seed cutting equipment to ensure optimal performance?

To maintain and calibrate seed cutting equipment for optimal performance, I follow these procedures:

- Regular cleaning and inspection: I clean and inspect equipment regularly, including blades, conveyors, and sensors, to remove debris and identify potential issues.

- Blade sharpening and replacement: I sharpen or replace cutting blades regularly to maintain their sharpness and prevent seed damage.

- Calibration of equipment: I calibrate equipment according to manufacturer specifications, using specialized tools and techniques to ensure accurate cutting.

- Preventive maintenance: I perform preventive maintenance tasks, such as lubrication and component replacement, to minimize equipment downtime and extend its lifespan.

6. What safety protocols do you follow when operating seed cutting equipment?

To ensure safety when operating seed cutting equipment, I adhere to the following protocols:

- Proper training: I have received comprehensive training on the safe operation of seed cutting equipment.

- Personal protective equipment: I wear appropriate personal protective equipment, such as safety glasses, gloves, and earplugs, to minimize potential hazards.

- Equipment safety features: I ensure that all equipment safety features, such as blade guards and emergency stop buttons, are in good working order.

- Safe operating procedures: I follow established safe operating procedures to minimize risks and prevent accidents.

7. How do you optimize seed cutting efficiency while minimizing waste?

To optimize seed cutting efficiency and minimize waste, I implement the following strategies:

- Proper equipment setup: I ensure that equipment is properly set up and calibrated to minimize seed damage and maximize yield.

- Batch optimization: I group similar seed types and sizes together to minimize blade changes and downtime.

- Seed conditioning: I pre-condition seeds to optimize their moisture content and enhance cut quality, reducing waste due to breakage or crushing.

- Waste reduction techniques: I employ techniques such as seed collection systems and blade sharpening to minimize seed loss and maximize utilization.

8. How do you stay up-to-date with the latest seed cutting technologies and best practices?

To stay up-to-date with the latest seed cutting technologies and best practices, I engage in the following activities:

- Industry conferences and seminars: I attend industry conferences and seminars to learn about new technologies, research findings, and best practices.

- Trade publications and journals: I read trade publications and journals to keep abreast of industry trends and advancements.

- Networking with peers: I network with colleagues and experts in the field to exchange knowledge and stay informed about emerging technologies.

- Continuing education: I pursue continuing education opportunities, such as workshops and online courses, to expand my knowledge and skills.

9. What is your understanding of seed viability and how do you ensure that cut seeds remain viable?

Seed viability refers to the ability of seeds to germinate and produce healthy plants. I take the following steps to ensure that cut seeds remain viable:

- Minimizing seed damage: I use sharp blades and employ proper cutting techniques to minimize seed damage and preserve viability.

- Appropriate seed storage: I store cut seeds in controlled environments with optimal temperature and humidity to maintain their viability.

- Seed testing: I conduct seed viability tests to assess the germination rate and ensure that cut seeds meet quality standards.

- Collaboration with plant scientists: I collaborate with plant scientists to stay informed about factors that affect seed viability and develop strategies to preserve it.

10. How do you handle and dispose of seed waste generated during the cutting process?

I handle and dispose of seed waste generated during the cutting process in an environmentally responsible manner, adhering to the following practices:

- Waste segregation: I segregate seed waste from other materials to prevent contamination.

- Composting: I compost biodegradable seed waste to create nutrient-rich soil amendments.

- Landfilling: I dispose of non-biodegradable seed waste in designated landfills according to local regulations.

- Waste minimization: I implement waste minimization strategies, such as optimizing cutting processes and reusing materials, to reduce waste generation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seed Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seed Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Seed Cutter is responsible for the safe and efficient operation of the seed cutting machine, ensuring high-quality seed production and minimizing waste.

1. Machine Operation and Maintenance

intro paragraph

- Operate the seed cutting machine according to established procedures and safety protocols.

- Perform routine maintenance and troubleshooting on the machine to ensure optimal performance.

2. Seed Preparation and Handling

intro paragraph

- Inspect and prepare seeds for cutting, ensuring they meet quality standards.

- Handle seeds carefully to prevent damage and preserve their viability.

3. Quality Control and Monitoring

intro paragraph

- Monitor the seed cutting process and adjust parameters as needed to ensure consistent quality.

- Conduct visual inspections and use quality control tools to identify and remove defective seeds.

4. Production and Efficiency

intro paragraph

- Meet production targets by optimizing machine settings and maximizing efficiency.

- Minimize waste and ensure efficient use of resources.

Interview Tips

Preparing thoroughly can greatly increase your chances of success in an interview. Here are some tips to help you ace your interview for the Seed Cutter position:

1. Research the Company and Position

Research the company’s website, annual reports, and industry news to gain insights into their business, values, and seed cutting operations. Understand the specific responsibilities of the Seed Cutter role and how they align with your skills and experience.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful, articulate answers that highlight your relevant skills and experiences. Practice these answers aloud to improve your delivery and confidence.

3. Showcase Your Technical Knowledge

Demonstrate your understanding of seed cutting machinery, quality control techniques, and industry best practices. Cite specific examples from your previous work experience that showcase your technical proficiency.

4. Emphasize Safety and Efficiency

Emphasize your commitment to safety protocols and your ability to operate the seed cutting machine efficiently. Share examples of how you have prioritized safety and maximized productivity in previous roles.

5. Prepare Questions for the Interviewer

Preparing questions for the interviewer shows your interest in the position and the company. Ask thoughtful questions about the company’s seed production process, growth opportunities for the role, and their commitment to sustainability.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Seed Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.