Are you gearing up for an interview for a Segmental Paver Installer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Segmental Paver Installer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

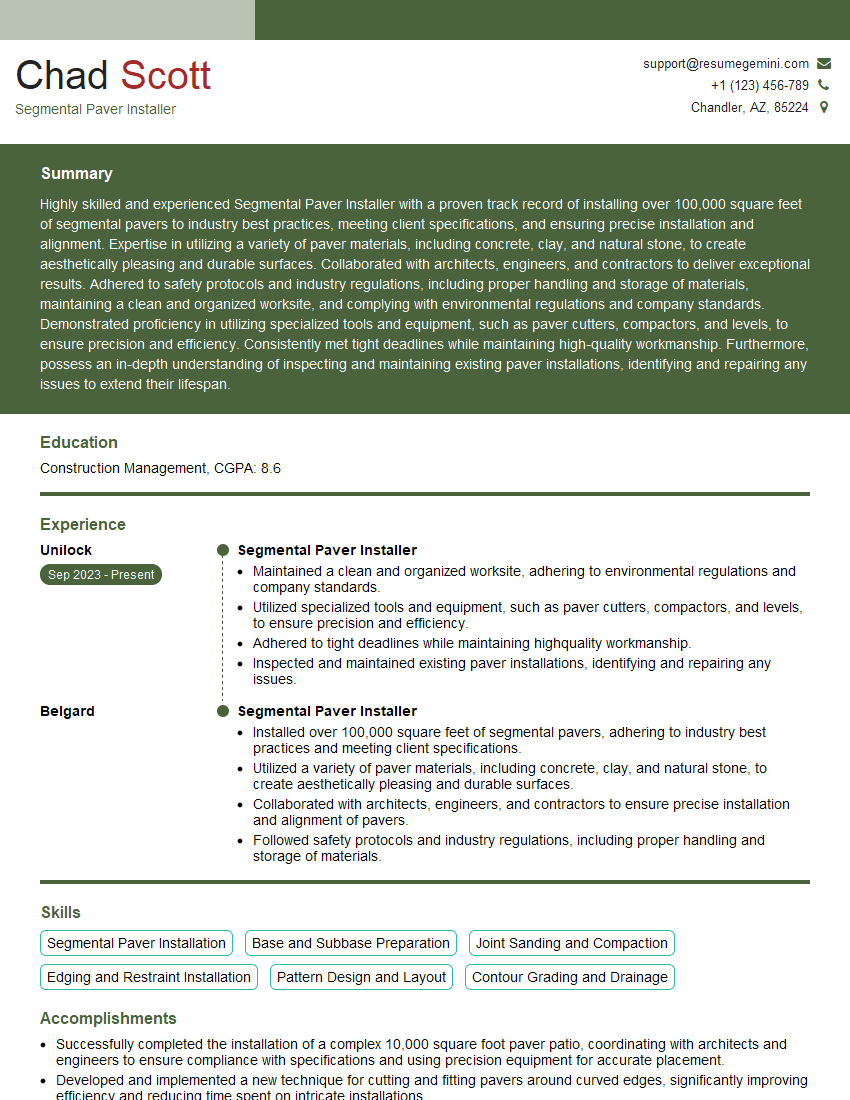

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Segmental Paver Installer

1. Explain the steps involved in preparing the subbase for a segmental paver installation?

The steps involved in preparing the subbase for a segmental paver installation include:

- Excavating the area to the desired depth.

- Compacting the soil to create a firm base.

- Installing a geotextile fabric to prevent weeds and other materials from migrating into the subbase.

- Adding a layer of crushed stone or gravel to create a stable base for the pavers.

- Compacting the subbase to ensure a level and stable surface.

2. What are the different types of jointing materials used for segmental pavers?

Mortar

- Used for heavy-duty applications with heavy traffic.

- Provides a strong and durable bond between pavers.

- Can be more difficult to install and requires specialized tools.

Polymeric sand

- Used for residential and light commercial applications with moderate traffic.

- Easy to install and can be applied with a broom.

- Provides a flexible bond that allows for some movement.

3. How do you determine the proper slope for a segmental paver installation?

The proper slope for a segmental paver installation depends on the intended use of the area and the local climate. In general, a slope of 1/4 inch per foot is recommended for residential applications and 1/2 inch per foot for commercial applications. The slope should be consistent throughout the entire installation and should be directed away from buildings and other structures to prevent water from pooling.

4. What are the common causes of segmental paver failure?

The common causes of segmental paver failure include:

- Improper subbase preparation leading to settlement or cracking.

- Insufficient drainage which can cause water to pool and freeze, leading to cracking or heaving.

- Use of improper jointing materials or inadequate compaction, leading to movement and separation of pavers.

- Excessive weight or impact loads, which can cause pavers to crack or break.

5. How do you handle drainage during a segmental paver installation?

Drainage is an important consideration for segmental paver installations. To ensure proper drainage, the following measures should be taken:

- The subbase should be sloped to direct water away from buildings and other structures.

- Geotextile fabric should be installed to prevent fines from clogging the drainage system.

- Catch basins or other drainage structures may be installed to collect and discharge water.

- Proper jointing materials should be used to prevent water from penetrating the surface and compromising the subbase.

6. What are the advantages of using segmental pavers over other paving materials?

Segmental pavers offer several advantages over other paving materials, including:

- Durability: Pavers are made of concrete or brick, which are highly durable materials that can withstand heavy loads and impact.

- Versatility: Pavers come in a wide variety of colors, shapes, and textures, allowing for endless design possibilities.

- Easy maintenance: Pavers can be easily repaired or replaced if they become damaged.

- Permeability: Pavers are porous, allowing water to infiltrate the ground and reducing runoff.

7. What are the different tools used in segmental paver installation?

The following tools are commonly used in segmental paver installation:

- Paver saw: For cutting pavers.

- Tamping plate: For compacting the subbase and pavers.

- Screed: For leveling the subbase and pavers.

- Jointing sand: For filling the joints between pavers.

- Broom: For sweeping jointing sand into the joints.

8. How do you ensure that segmental pavers are level and aligned?

To ensure that segmental pavers are level and aligned, the following steps should be taken:

- The subbase should be properly compacted and graded to provide a level surface.

- String lines should be used to guide the installation and ensure that the pavers are aligned.

- A screed or straight edge can be used to level the pavers and ensure that they are flush with each other.

- A tamping plate or other compaction tool should be used to firmly seat the pavers in place.

9. How do you handle obstacles such as trees or underground utilities during a segmental paver installation?

When encountering obstacles such as trees or underground utilities during a segmental paver installation, the following steps should be taken:

- Identify the location of the obstacle and mark it.

- Cut the pavers around the obstacle, using a paver saw or other appropriate tool.

- Compact the subbase around the obstacle.

- Install the pavers around the obstacle, ensuring that they are level and aligned.

- Use jointing sand to fill the joints between the pavers and the obstacle.

10. What safety precautions should be taken when installing segmental pavers?

The following safety precautions should be taken when installing segmental pavers:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Use caution when operating power tools, such as paver saws and tampers.

- Be aware of overhead hazards, such as power lines and trees.

- Work in well-ventilated areas to avoid inhaling dust or fumes.

- Take breaks and stay hydrated, especially when working in hot weather.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Segmental Paver Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Segmental Paver Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Segmental Paver Installers work in outdoor environments to create patios, walkways, and other surfaces using pre-cast concrete pavers. Their responsibilities include:

1. Site Preparation

Preparing the installation site by clearing the area, leveling the ground, and installing a base layer of crushed stone or gravel.

- Determining the proper depth and slope for the base layer.

- Compacting the base layer to ensure a stable foundation.

2. Paver Installation

Installing the pavers according to the design plan, ensuring they are level, aligned, and properly spaced.

- Cutting pavers to fit around obstacles or create curves.

- Using specialized tools and equipment to set the pavers in place.

3. Grouting

Applying grout between the pavers to fill any gaps and secure them in place.

- Mixing the grout according to the manufacturer’s instructions.

- Applying the grout using a grout bag or squeegee.

4. Finishing

Completing the installation by cleaning the pavers, removing excess grout, and applying a sealant to protect the surface.

- Using a power washer or broom to clean the pavers.

- Applying a sealant to protect the pavers from weathering and fading.

Interview Tips

To ace an interview for a Segmental Paver Installer position, follow these tips:

1. Research the Company and Industry

Learn about the company’s history, values, and current projects. Understanding the industry’s trends and best practices will demonstrate your interest and knowledge.

- Visit the company’s website and social media pages.

- Read industry publications and attend trade shows.

2. Highlight Your Skills and Experience

Emphasize your proficiency in site preparation, paver installation, grouting, and finishing techniques. Quantify your experience by providing specific examples of projects you have completed.

- Use the STAR method (Situation, Task, Action, Result) to describe your accomplishments.

- Be prepared to discuss your knowledge of different paver materials and installation methods.

3. Showcase Your Physical Abilities

Segmental Paver Installers must be physically fit to perform demanding tasks. Highlight your strength, endurance, and attention to detail.

- Mention any relevant certifications or training, such as OSHA safety certifications.

- Emphasize your ability to work independently and as part of a team.

4. Express Your Passion for the Trade

Convey your enthusiasm for creating beautiful and durable outdoor spaces. Explain why you are drawn to the field and what motivates you to excel.

- Share examples of projects you have worked on that you are particularly proud of.

- Discuss your interest in staying up-to-date with industry advancements.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Segmental Paver Installer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.