Feeling lost in a sea of interview questions? Landed that dream interview for Semiautomatic Ultrasonic Seaming Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Semiautomatic Ultrasonic Seaming Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

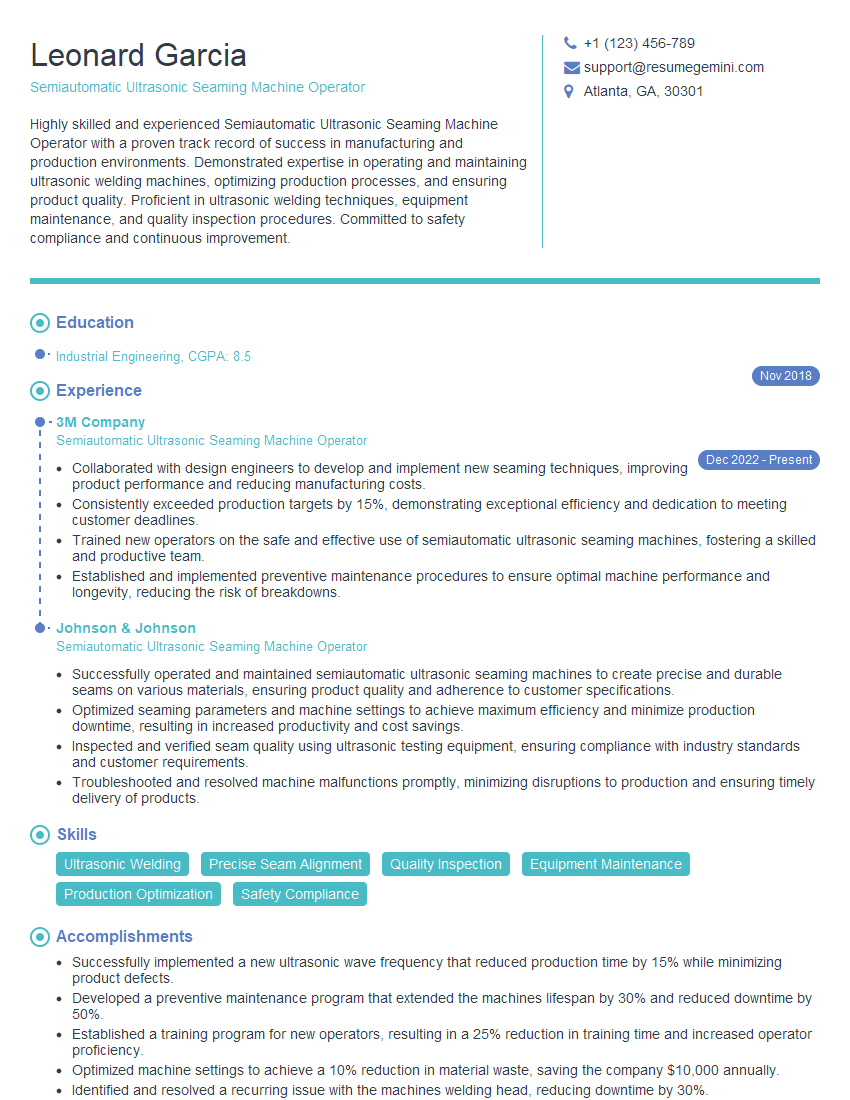

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiautomatic Ultrasonic Seaming Machine Operator

1. Explain the working principle of a semiautomatic ultrasonic seaming machine?

The machine uses high-frequency ultrasonic waves to create frictional heat between two or more layers of fabric, causing them to bond together. The ultrasonic waves are generated by a transducer and transmitted through a horn, which directs the energy to the fabric. The pressure applied by the horn helps to create a strong bond between the layers.

2. What are the different types of ultrasonic seaming machines?

Manual

- Requires an operator to manually move the fabric through the machine.

- Suitable for small-scale production or custom work.

Semiautomatic

- The operator loads the fabric into the machine, and the machine automatically moves it through the seaming process.

- Faster and more efficient than manual machines.

Automatic

- Fully automated, with the machine handling all aspects of the seaming process.

- Fastest and most efficient type of ultrasonic seaming machine.

3. What are the main components of a semiautomatic ultrasonic seaming machine?

- Ultrasonic transducer

- Horn

- Anvil

- Pneumatic press

- Control panel

4. How do you set up and operate a semiautomatic ultrasonic seaming machine?

- Mount the horn on the machine.

- Adjust the height of the horn to match the thickness of the fabric.

- Set the operating parameters (power, frequency, and speed) on the control panel.

- Load the fabric into the machine and align it under the horn.

- Start the machine and allow the horn to descend and apply pressure to the fabric.

- Monitor the seaming process and make adjustments as needed.

5. What are the common problems that can occur when operating a semiautomatic ultrasonic seaming machine?

- Poor seam quality

- Fabric damage

- Machine breakdowns

6. How do you troubleshoot and resolve common problems with a semiautomatic ultrasonic seaming machine?

- Check the horn for damage or wear.

- Inspect the anvil for damage or contamination.

- Check the pneumatic press for air leaks.

- Check the control panel for loose connections or faulty components.

7. What are the safety precautions that must be taken when operating a semiautomatic ultrasonic seaming machine?

- Wear ear protection, as the machine generates high-frequency noise.

- Wear safety glasses to protect your eyes from flying debris.

- Keep your hands away from the moving parts of the machine.

- Do not operate the machine if it is damaged or malfunctioning.

8. What are the maintenance procedures for a semiautomatic ultrasonic seaming machine?

- Clean the horn and anvil regularly.

- Inspect the pneumatic press for leaks.

- Check the control panel for loose connections or faulty components.

- Lubricate the moving parts of the machine.

9. What are the quality control procedures for ultrasonic seams?

- Inspect the seams for defects, such as holes, tears, or wrinkles.

- Test the seams for strength and durability.

- Ensure that the seams meet the required specifications.

10. What are the advantages of using a semiautomatic ultrasonic seaming machine over other seaming methods?

- Strong, durable seams

- No needle or thread required

- Fast and efficient

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiautomatic Ultrasonic Seaming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiautomatic Ultrasonic Seaming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Semiautomatic Ultrasonic Seaming Machine Operators are responsible for operating semiautomatic ultrasonic sewing equipment to join similar or dissimilar materials together. The job requires proficiency in machine operation, material handling, and quality control.

1. Machine Operation

Set up and operate semiautomatic ultrasonic sewing equipment according to standard operating procedures.

- Load and unload materials.

- Adjust machine settings, speed, temperature, and pressure.

- Monitor machine performance and make necessary adjustments.

- Troubleshoot and resolve minor machine malfunctions.

2. Material Handling

Handle materials, and ensure proper alignment for accurate seams.

- Inspect materials for defects or damage.

- Load and unload materials onto the machine.

- Align materials properly for accurate seams.

- Remove finished products from the machine.

3. Quality Control

Inspect finished products for quality and accuracy.

- Check seams for strength, uniformity, and aesthetics.

- Identify and correct defects.

- Maintain quality records and report any issues.

- Conduct scheduled maintenance on equipment.

4. Safety and Compliance

Follow all safety protocols and regulations.

- Wear appropriate safety gear.

- Operate machines safely and cautiously.

- Comply with all safety regulations and procedures.

- Maintain a clean and organized work area.

Interview Tips

To ace an interview for a Semiautomatic Ultrasonic Seaming Machine Operator position, candidates should prepare thoroughly and demonstrate their skills and experience.

1. Research the Company and Position

Learn about the company’s products or services, industry, and culture.

- Review the job description thoroughly.

- Identify key skills and responsibilities required for the role.

2. Highlight Relevant Skills and Experience

In your resume and interview, emphasize skills and experience that are directly relevant to the job.

- Quantify your accomplishments whenever possible.

- Provide specific examples of your machine operation, material handling, and quality control expertise.

3. Practice Answering Common Interview Questions

Familiarize yourself with common interview questions and prepare your answers.

- Tell me about your experience operating semiautomatic ultrasonic sewing equipment.

- Describe your process for ensuring the quality of finished products.

- How do you handle machine malfunctions or unexpected situations?

- What is your knowledge of safety protocols and regulations in the manufacturing industry?

4. Be Enthusiastic and Professional

Show your enthusiasm for the position and the industry.

- Dress professionally for the interview.

- Maintain eye contact and speak clearly.

- Ask thoughtful questions about the company and the position.

Next Step:

Now that you’re armed with the knowledge of Semiautomatic Ultrasonic Seaming Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Semiautomatic Ultrasonic Seaming Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini