Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Semiconductor Bonder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Semiconductor Bonder so you can tailor your answers to impress potential employers.

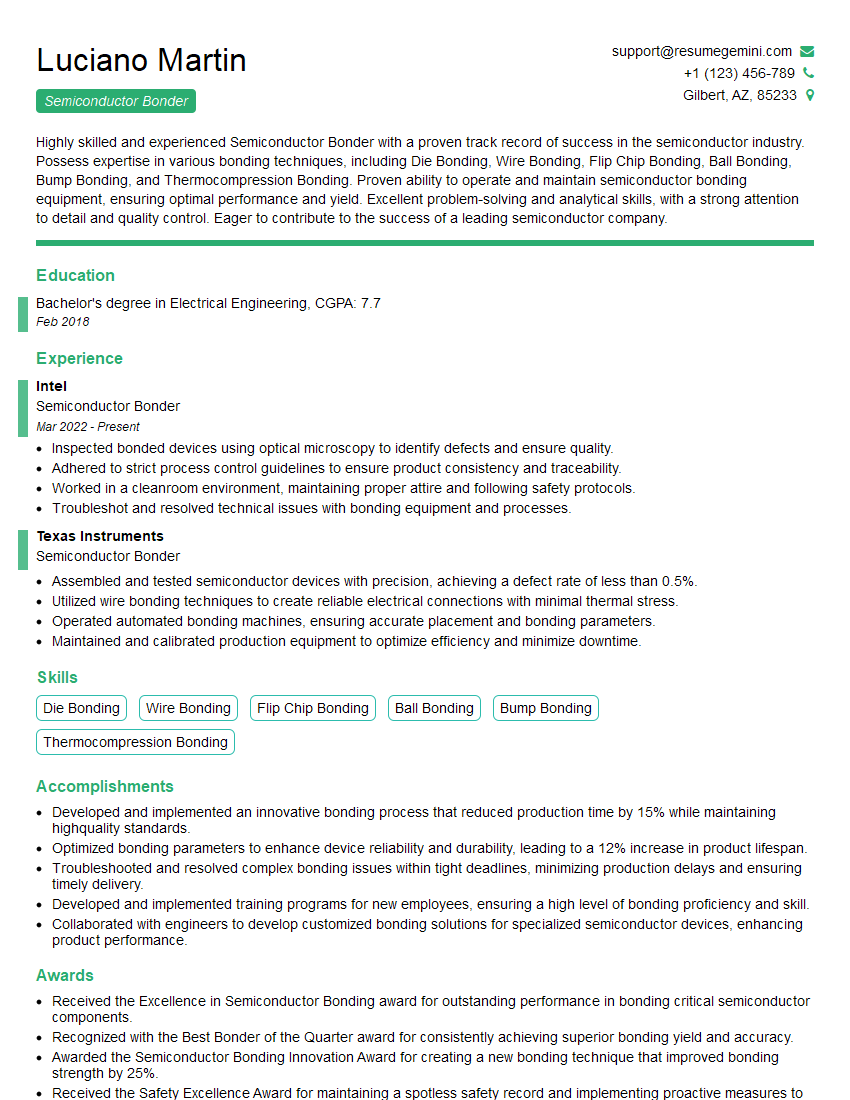

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Bonder

1. What are the different types of semiconductor bonding techniques?

There are three main types of semiconductor bonding techniques:

- Wire bonding

- Flip chip bonding

- Tape automated bonding (TAB)

2. What are the advantages and disadvantages of each bonding technique?

Wire bonding

- Advantages: Low cost, mature technology, and does not require high precision equipment.

- Disadvantages: Can be time-consuming, and the wires can be fragile.

Flip chip bonding

- Advantages: High-speed, high-density, and low-cost.

- Disadvantages: Requires high precision equipment, and the yield can be lower than other methods.

TAB

- Advantages: High-speed, high-density, and low-cost.

- Disadvantages: Can be difficult to align the tape, and the yield can be lower than other methods.

3. What are the key considerations when selecting a semiconductor bonding technique?

- Type of semiconductor device

- Package size and shape

- Production volume

- Cost

- Reliability

4. What are the common problems that can occur during semiconductor bonding?

- Bonding wire breakage

- Flip chip delamination

- TAB alignment errors

- Voiding in the bond

- Contamination

5. How do you troubleshoot semiconductor bonding problems?

- Inspect the bond area for any visible defects.

- Check the bonding parameters and compare them to the manufacturer’s recommendations.

- Perform a bond pull test to determine the bond strength.

- Use an X-ray or other inspection method to look for voids or other internal defects.

- Consult with the manufacturer or a bonding specialist.

6. What are the safety precautions that must be taken when working with semiconductor bonding equipment?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Handle chemicals with care and follow the manufacturer’s instructions.

- Be aware of the potential for electrical hazards and take appropriate precautions.

- Keep the work area clean and free of clutter.

- Follow all safety procedures and guidelines.

7. What are the latest trends in semiconductor bonding technology?

- Increased use of automation

- Development of new bonding materials and techniques

- Focus on high-density and high-speed bonding

- Integration of bonding with other semiconductor processes

8. What are the challenges facing the semiconductor bonding industry?

- The need for higher precision and reliability

- The increasing complexity of semiconductor devices

- The need for lower costs

- The shortage of skilled workers

9. What do you think the future of semiconductor bonding technology?

- Increased use of automation and robotics

- Development of new bonding materials and techniques

- Integration of bonding with other semiconductor processes

- Focus on high-density and high-speed bonding

10. What are your strengths and weaknesses as a semiconductor bonder?

- Excellent problem-solving skills

- Strong attention to detail

- Experience with a variety of semiconductor bonding techniques

- Ability to work independently and as part of a team

- Excellent communication skills

- Lack of experience with certain types of semiconductor devices

- Need to improve my speed and efficiency

- Can be impatient at times

Strengths:

Weaknesses:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Bonder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Bonder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Semiconductor Bonder is a skilled professional responsible for operating and maintaining semiconductor bonding equipment. They play a crucial role in the manufacturing process of electronic devices, ensuring precise and reliable bonding of semiconductor wafers.

1. Equipment Operation and Maintenance

Operate and maintain semiconductor bonding equipment, including wire bonders, thermal compression bonders, and ultrasonic bonders.

- Set up and calibrate equipment according to process specifications.

- Monitor equipment performance and make necessary adjustments to optimize bonding parameters.

- Perform routine maintenance and troubleshooting to ensure equipment reliability.

2. Bonding Process Control

Control the bonding process to ensure the quality and reliability of the bonded products.

- Monitor bonding parameters such as temperature, pressure, and bonding time.

- Inspect bonded products using optical microscopes and other testing equipment.

- Identify and correct defects in the bonding process.

3. Process Development and Improvement

Participate in the development and improvement of semiconductor bonding processes.

- Evaluate new bonding materials and techniques.

- Suggest process improvements to enhance bonding quality and efficiency.

- Collaborate with engineers and other stakeholders to optimize the bonding process.

4. Quality Control and Assurance

Adhere to quality control and assurance procedures to ensure the integrity of the bonded products.

- Follow documented work instructions and process specifications.

- Maintain accurate records of bonding parameters and inspection results.

- Participate in quality audits and reviews to identify potential issues.

Interview Tips

Preparing for a Semiconductor Bonder interview requires thorough research and practice. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Semiconductor Bonder position. Familiarize yourself with the company’s products, services, and industry standing. Understand the key responsibilities and qualifications for the role.

2. Practice Your Answers

Prepare thoughtful answers to common interview questions related to semiconductor bonding. Practice your responses to questions about your experience, technical skills, and problem-solving abilities. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and highlight your accomplishments.

3. Highlight Your Technical Skills

Emphasize your technical proficiency in semiconductor bonding. Discuss your experience with specific equipment, bonding processes, and quality control procedures. Quantify your accomplishments and provide specific examples to demonstrate your skills.

4. Demonstrate Your Problem-Solving Abilities

Interviewers often assess problem-solving abilities during Semiconductor Bonder interviews. Be prepared to discuss how you handled challenging situations in your previous roles. Explain your thought process and the steps you took to resolve issues efficiently.

5. Prepare Questions for the Interviewer

Asking insightful questions at the end of the interview shows your interest and engagement. Prepare thoughtful questions about the company, the semiconductor bonding process, or the future of the industry. This demonstrates your eagerness to learn and your passion for the field.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Semiconductor Bonder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!