Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Semiconductor Manufacturing Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

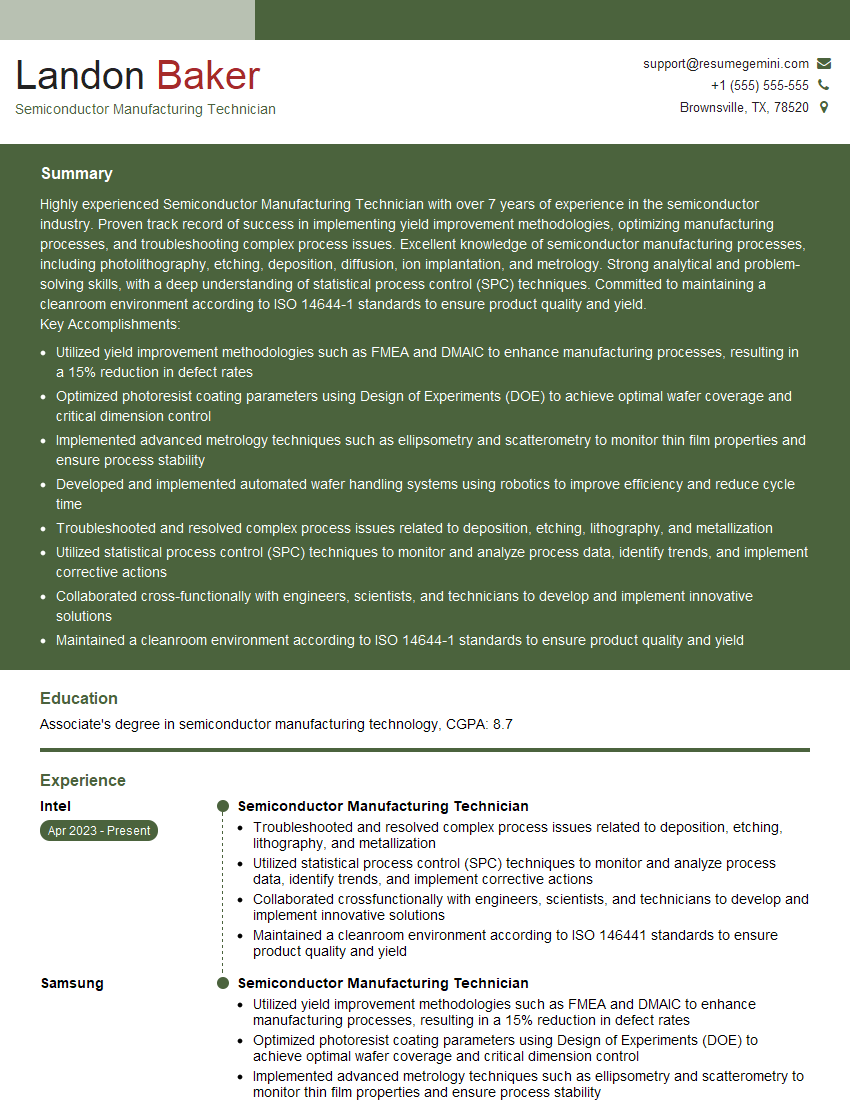

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Manufacturing Technician

1. What would you do if you noticed a sudden drop in the yield of wafers?

- Check the equipment for any malfunctions or calibration issues.

- Inspect the wafers for any defects or contamination.

- Review the process parameters to identify any deviations.

- Consult with colleagues and supervisors to gather insights.

- Implement corrective actions and monitor the results to restore yield.

2. How do you interpret data from process control charts?

Identifying trends and patterns

- Analyze the data points to identify any significant trends or patterns.

- Determine the center line and control limits to assess process stability.

Taking corrective actions

- Identify assignable causes of variation beyond the control limits.

- Implement corrective actions to bring the process back into control.

3. Describe your experience in troubleshooting semiconductor manufacturing equipment.

– Experience in diagnosing and resolving hardware and software issues. – Ability to use diagnostic tools and perform root cause analysis. – Understanding of equipment specifications and maintenance procedures. – Efficient troubleshooting techniques to minimize downtime.

4. How do you handle the delicate nature of wafers during processing?

– Use proper handling techniques to prevent damage. – Wear gloves and ESD-safe clothing. – Handle wafers with care, avoiding contact with edges or surfaces. – Use wafer carriers and transport systems to minimize contamination.

5. Explain the importance of maintaining a cleanroom environment.

– Prevention of contamination and defects in semiconductor devices. – Control of temperature, humidity, and particulate levels. – Use of cleanroom suits, gloves, and other protective gear. – Regular cleaning and maintenance of equipment and surfaces. – Compliance with industry standards and regulations.

6. Describe your understanding of photolithography and its role in semiconductor manufacturing.

– Transferring circuit patterns onto wafers using light-sensitive materials. – Use of photoresist, masks, and exposure tools. – Processes of development, etching, and stripping. – Importance of precision and accuracy in patterning.

7. What safety precautions are essential when working with hazardous chemicals?

– Use of personal protective equipment (PPE) such as gloves, goggles, and respirators. – Proper handling and storage of chemicals. – Knowledge of Material Safety Data Sheets (MSDSs). – Emergency response procedures for spills or accidents.

8. How do you ensure the traceability of wafers throughout the manufacturing process?

– Use of unique identifiers and tracking systems. – Maintaining accurate and timely documentation. – Tracing wafers through all processing steps. – Importance for quality control and defect analysis.

9. Explain the concept of statistical process control (SPC) and its applications in semiconductor manufacturing.

– Monitoring and controlling processes using statistical techniques. – Use of control charts and other data analysis methods. – Identifying and eliminating sources of variation. – Improving process stability and reducing defects.

10. How do you stay updated on advancements in semiconductor manufacturing technology?

– Attending industry conferences and workshops. – Reading technical journals and articles. – Participating in training programs and certifications. – Networking with peers and experts in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Manufacturing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Manufacturing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Semiconductor Manufacturing Technician plays a pivotal role in the production of semiconductor devices, ensuring their quality and reliability. Their responsibilities encompass a wide range of tasks, including:

1. Equipment Operation and Maintenance

Operate and maintain semiconductor manufacturing equipment, including photolithography machines, deposition systems, and etching tools.

- Calibrate and troubleshoot equipment to optimize performance and minimize downtime.

- Monitor equipment parameters and make adjustments as needed to ensure product specifications are met.

2. Process Control and Monitoring

Monitor and control production processes, ensuring that they adhere to established procedures and specifications.

- Inspect wafers and devices at various stages of production to identify defects and non-conformances.

- Take corrective actions to resolve process issues and maintain product quality.

3. Data Collection and Analysis

Collect and analyze data from manufacturing processes to identify trends and areas for improvement.

- Use statistical process control techniques to analyze data and identify potential problems.

- Recommend process modifications and equipment upgrades to enhance productivity and reduce costs.

4. Problem Solving and Troubleshooting

Troubleshoot and resolve technical issues that arise during production.

- Analyze error logs and equipment diagnostics to identify root causes of problems.

- Work with engineers and other technicians to develop and implement solutions.

Interview Tips

To ace an interview for a Semiconductor Manufacturing Technician role, it is essential to prepare thoroughly and demonstrate your technical skills and problem-solving abilities. Here are some tips to help you succeed:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and current projects. Research the semiconductor industry to understand the latest trends and technological advancements.

- Read the company’s website, news releases, and annual reports.

- Attend industry events and webinars to gain insights into the latest developments.

2. Prepare for Technical Questions

Be ready to answer questions about your experience with semiconductor manufacturing equipment, processes, and troubleshooting techniques. Review your resume and highlight your relevant skills and accomplishments.

- Practice answering questions about specific equipment you have operated, such as photolithography machines or etching tools.

- Prepare examples of problems you have solved and the steps you took to resolve them.

3. Emphasize Your Problem-Solving Abilities

In this role, problem-solving is crucial. Highlight your analytical skills and ability to identify and resolve issues in a timely manner.

- Share examples of how you have successfully diagnosed and fixed equipment problems.

- Describe your experience using statistical process control techniques to improve production processes.

4. Showcase Your Communication Skills

Effective communication is essential for collaborating with colleagues and resolving production issues. Demonstrate your ability to clearly articulate technical information and work in a team environment.

- Practice answering questions about your experience working with other technicians and engineers.

- Highlight your ability to write technical reports and present your findings.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Semiconductor Manufacturing Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!