Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Semiconductor Packages Sealer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Semiconductor Packages Sealer so you can tailor your answers to impress potential employers.

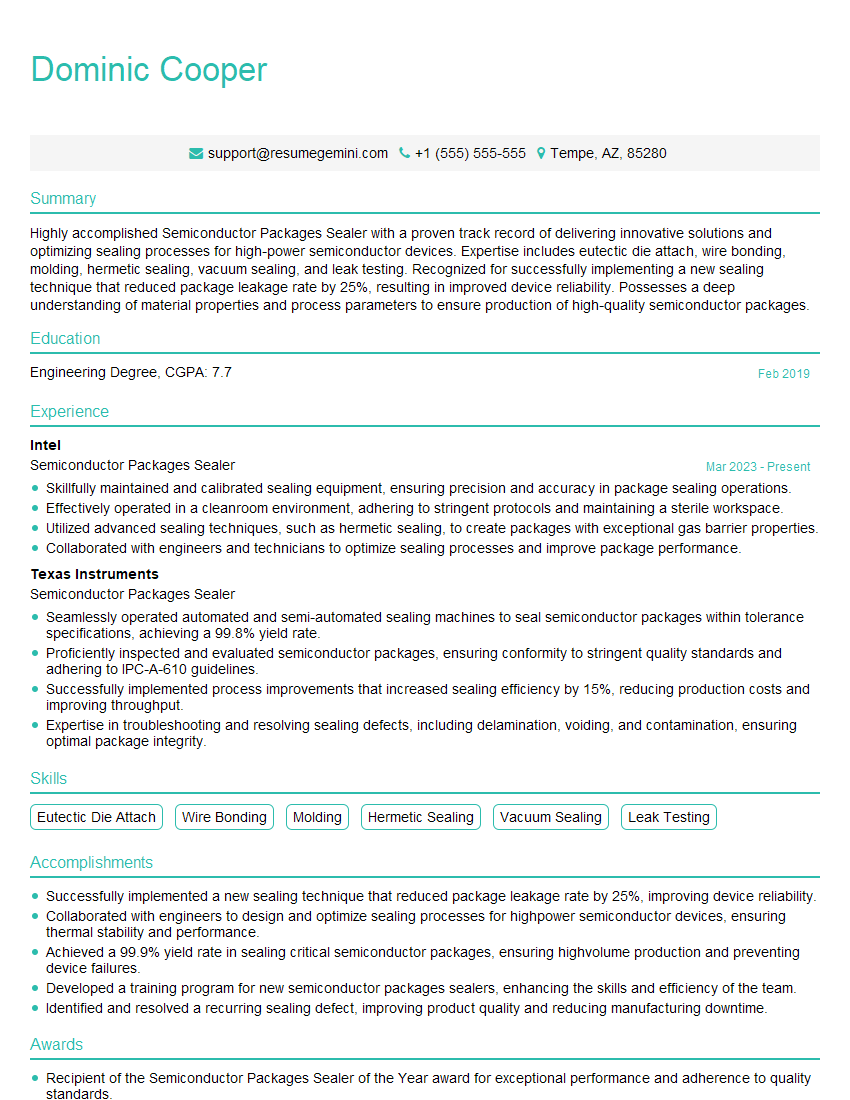

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Packages Sealer

1. What are the different types of semiconductor packages and their applications?

- Dual In-line Package (DIP): Used in through-hole mounting, commonly found in older electronic devices.

- Quad Flat Package (QFP): Surface-mount package with pins on all four sides, used in high-density applications.

- Ball Grid Array (BGA): Surface-mount package with solder balls on the bottom, providing high I/O count and improved thermal performance.

- Small Outline Integrated Circuit (SOIC): Surface-mount package with gull-wing leads, suitable for high-volume production.

- Thin Small Outline Package (TSOP): Ultra-thin surface-mount package, commonly used in portable electronics.

2. Describe the process of semiconductor packaging sealing.

Pre-sealing Preparation:

- Inspecting packages for defects and ensuring cleanliness.

- Applying underfill material to improve package integrity.

Sealing:

- Choosing the appropriate sealing material (e.g., epoxy, silicone).

- Dispensing the sealing material around the package edge.

- Curing the seal using heat, UV light, or a combination of both.

Post-sealing Inspection:

- Examining the sealed package for leaks or defects.

- Performing electrical tests to ensure package integrity.

3. What are the key quality control measures involved in semiconductor package sealing?

- Monitoring sealing material properties (e.g., viscosity, cure time).

- Verifying sealing equipment performance (e.g., temperature, dispensing accuracy).

- Conducting visual inspections for defects (e.g., cracks, voids).

- Performing environmental stress tests (e.g., temperature cycling, humidity)

- Adhering to industry standards and specifications.

4. What are the common challenges faced during semiconductor package sealing?

- Leaks: Ensuring a hermetic seal is crucial to prevent moisture ingress.

- Package Deformation: High sealing temperatures can cause packages to warp or crack.

- Material Compatibility: The sealing material must be compatible with the package materials to avoid delamination.

- Containment: Preventing the sealing material from contaminating other components is essential.

- Process Optimization: Finding the ideal combination of material, process parameters, and equipment to achieve high yield.

5. Describe the role of moisture sensitivity in semiconductor package sealing.

- Moisture can cause corrosion, delamination, and electrical failure within packages.

- Sealing packages in dry environments using moisture-resistant materials is crucial.

- Packages must be stored and handled properly to prevent moisture absorption.

- Implementing package drying techniques (e.g., baking) prior to sealing can remove moisture.

- Adhering to moisture sensitivity levels (MSL) is essential to ensure package integrity.

6. What are the different techniques used to test semiconductor package seals?

- Pressure Decay Test: Detecting leaks by measuring pressure changes within the package.

- Fine and Gross Leak Test: Using helium or other tracer gases to identify leaks.

- Dye Penetration Test: Visual inspection after immersing the package in a dye solution.

- X-ray Inspection: Identifying internal voids or defects.

- Scanning Acoustic Microscopy (SAM): Detecting delamination or cracks using sound waves.

7. What is the importance of process control in semiconductor package sealing?

- Ensures consistent product quality and performance.

- Reduces production defects and rework costs.

- Facilitates troubleshooting and process optimization.

- Maintains compliance with industry standards and customer specifications.

- Improves overall manufacturing efficiency.

8. Describe the safety precautions necessary during semiconductor package sealing.

- Chemical Handling: Using proper personal protective equipment and following safe handling procedures.

- High Temperatures: Wearing heat-resistant gloves and clothing when working with hot sealing equipment.

- Compressed Gas: Handling gas cylinders and connections safely to prevent explosions.

- Cleanroom Environment: Maintaining a clean and static-free environment to prevent contamination.

- Training and Certification: Ensuring all personnel are adequately trained and certified.

9. What are the latest advancements in semiconductor package sealing technology?

- Glass-Encapsulated Packages: Providing high thermal conductivity and improved sealing reliability.

- Ultrasonic Sealing: Using ultrasonic energy to create a hermetic seal, reducing sealing temperature.

- Advanced Materials: Developing new materials with improved adhesion, thermal stability, and moisture resistance.

- Automated Inspection Systems: Using AI and machine vision to enhance seal quality and reduce defects.

- Cloud-Based Monitoring: Enabling remote monitoring of sealing processes and data analysis.

10. How do you stay up-to-date with industry best practices and advancements in semiconductor package sealing?

- Attending industry conferences and workshops.

- Reading technical papers and journals.

- Networking with peers and experts in the field.

- Participating in training and certification programs.

- Staying informed through online resources and forums.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Packages Sealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Packages Sealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Semiconductor Packages Sealer is responsible for sealing semiconductor packages in a manner that meets quality standards.

1. Prepare work area

Prepare work area by cleaning and setting up equipment and materials.

- Follow established procedures and maintain a clean and organized work environment.

- Maintain proper inventory of materials to ensure efficient operation.

2. Operate sealing equipment

Operate sealing equipment to seal semiconductor packages.

- Use proper techniques and follow established procedures to ensure proper sealing.

- Monitor equipment performance and make necessary adjustments to maintain optimal operation.

3. Inspect sealed packages

Inspect sealed packages to ensure they meet quality standards.

- Visually inspect packages for defects and damage.

- Conduct tests to verify seal integrity and performance.

4. Troubleshoot and resolve issues

Troubleshoot and resolve issues with sealing equipment and processes.

- Identify and diagnose problems based on symptoms and observations.

- Implement corrective actions to restore equipment and processes to optimal performance.

Interview Tips

Interviewing for a job can be a nerve-wracking experience, but by following a few simple tips, you can increase your chances of success.

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture and what they’re looking for in a candidate.

- Visit the company’s website and social media pages.

- Read news articles and industry blogs about the company.

- Talk to people in your network who may know about the company or the position.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Be specific and provide examples when answering questions.

- Practice your answers out loud so that you can become more comfortable with them.

3. Dress professionally and arrive on time

Your appearance and punctuality say a lot about you, so it’s important to dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you’re serious about the position.

- Choose clothing that is appropriate for the company culture and the position you’re applying for.

- Make sure your clothes are clean and pressed.

- Arrive at the interview on time, or even a few minutes early.

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position, and to show that you’re interested and engaged.

- Prepare a few questions to ask the interviewer.

- Your questions should be specific and relevant to the position and the company.

- Don’t be afraid to ask clarifying questions if you don’t understand something.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Semiconductor Packages Sealer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Semiconductor Packages Sealer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.