Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Semiconductor Processing Equipment Production Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Semiconductor Processing Equipment Production Technician so you can tailor your answers to impress potential employers.

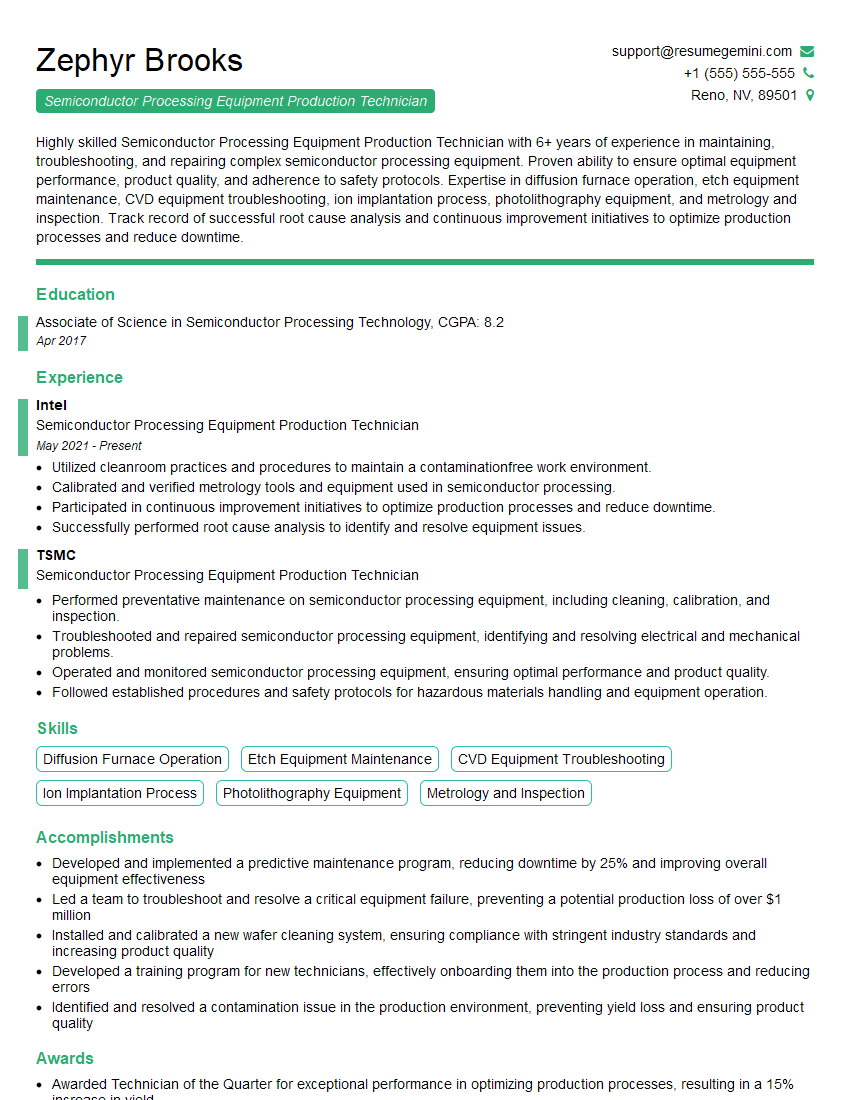

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Processing Equipment Production Technician

1. How do you ensure that the semiconductor processing equipment is calibrated and maintained according to specification?

- Perform regular calibration checks using certified standards.

- Maintain a calibration schedule and documentation.

- Follow established maintenance procedures and use validated spare parts.

- Monitor equipment performance data and identify any deviations from specifications.

- Troubleshoot and resolve any equipment issues promptly.

2. What are the key safety protocols you must adhere to when working with semiconductor processing equipment?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and lab coat.

- Follow lock-out/tag-out procedures before servicing equipment.

- Handle hazardous chemicals with caution and follow proper disposal protocols.

- Be aware of potential electrical hazards and take precautions to prevent shocks.

- Report any safety concerns or incidents immediately to supervisor.

3. How do you monitor and control process parameters to ensure product quality?

- Use in-situ sensors and monitoring systems to track critical parameters.

- Set process control limits and monitor data for deviations.

- Calibrate and maintain monitoring equipment regularly.

- Identify and correct any process deviations promptly.

- Document all process parameters and variations.

4. Describe the steps involved in troubleshooting and resolving equipment malfunctions.

- Isolate the issue to a specific equipment or component.

- Review maintenance history and equipment logs for potential clues.

- Perform diagnostic tests and inspections to identify the root cause.

- Replace or repair faulty components using approved parts.

- Test the equipment and verify that the issue is resolved.

5. How do you manage spare parts inventory and ensure availability for production?

- Maintain a comprehensive inventory of critical spare parts.

- Monitor inventory levels and reorder parts as needed.

- Establish a system for tracking part usage and identifying potential shortages.

- Work with suppliers to secure expedited delivery of parts.

- Optimize spare parts stock levels to minimize downtime.

6. Describe your experience in working with cleanroom environments and maintaining contamination control.

- Followed gowning and glove-wearing protocols.

- Used ESD-safe materials and grounding techniques.

- Minimized particle generation and contamination.

- Monitored cleanroom conditions and identified potential sources of contamination.

- Participated in cleanroom audits and certification processes.

7. How do you stay up-to-date with the latest advancements and best practices in semiconductor processing equipment?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Engage in online forums and discussion groups.

- Receive training from equipment manufacturers and suppliers.

- Seek mentorship from experienced engineers in the field.

8. What is your understanding of semiconductor manufacturing processes, such as lithography, etching, and deposition?

- Basic understanding of semiconductor manufacturing steps.

- Knowledge of the equipment used in these processes.

- Awareness of the critical parameters and quality control measures involved.

- Interest in learning more about the technical details of these processes.

9. Describe your experience in using data analysis tools and techniques to improve equipment performance and yield.

- Proficient in using statistical process control (SPC) tools.

- Experience in data mining and analysis.

- Ability to identify trends and patterns in data.

- Developed and implemented solutions to improve equipment reliability and yield.

10. How do you prioritize your work and manage multiple tasks in a fast-paced production environment?

- Prioritize tasks based on urgency and impact.

- Use a task management system to track progress and deadlines.

- Delegate tasks and responsibilities effectively.

- Communicate regularly with colleagues and supervisors.

- Remain calm and focused under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Processing Equipment Production Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Processing Equipment Production Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Semiconductor Processing Equipment Production Technicians are responsible for the production and maintenance of semiconductor processing equipment. They work in a cleanroom environment and must follow strict safety protocols. Their key responsibilities include:

1. Equipment Assembly

Assemble and install semiconductor processing equipment according to specifications.

- Follow blueprints and schematics to assemble and install equipment.

- Ensure that all components are properly connected and functioning.

2. Equipment Maintenance

Perform preventive maintenance and repairs on semiconductor processing equipment.

- Inspect equipment for wear and tear.

- Replace worn or damaged parts.

- Calibrate and adjust equipment to ensure optimal performance.

3. Process Development

Assist in the development and implementation of new semiconductor processing techniques.

- Work with engineers and scientists to develop new processes.

- Test and evaluate new processes to ensure that they meet specifications.

4. Quality Control

Inspect and test semiconductor wafers to ensure that they meet quality standards.

- Use microscopes and other equipment to inspect wafers for defects.

- Perform electrical tests to ensure that wafers are functioning properly.

Interview Tips

To ace the interview for a Semiconductor Processing Equipment Production Technician position, it is important to prepare thoroughly. Here are some tips:

1. Research the Company and the Position

Learn about the company’s history, products, and culture. Research the specific position you are applying for and the key responsibilities.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people who work in the semiconductor industry.

2. Practice Your Answers to Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself” and “Why are you interested in this position?”. Practice your answers out loud so that you can deliver them confidently.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments whenever possible.

- Be enthusiastic and positive.

3. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview. Arrive on time and be prepared to shake hands with the interviewer.

- Wear a suit or business casual attire.

- Be punctual.

- Make eye contact and smile.

4. Be Yourself and Be Honest

The interviewer wants to get to know you, so be yourself and be honest about your skills and experience. Don’t try to be someone you’re not.

- Be authentic.

- Be transparent.

- Be confident.

5. Ask Questions

At the end of the interview, be sure to ask questions about the company, the position, and the next steps in the process. This shows that you are interested and engaged.

- Ask about the company’s culture.

- Ask about the training and development opportunities.

- Ask about the company’s plans for the future.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Semiconductor Processing Equipment Production Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.