Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Semiconductor Wafers and Components Plater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

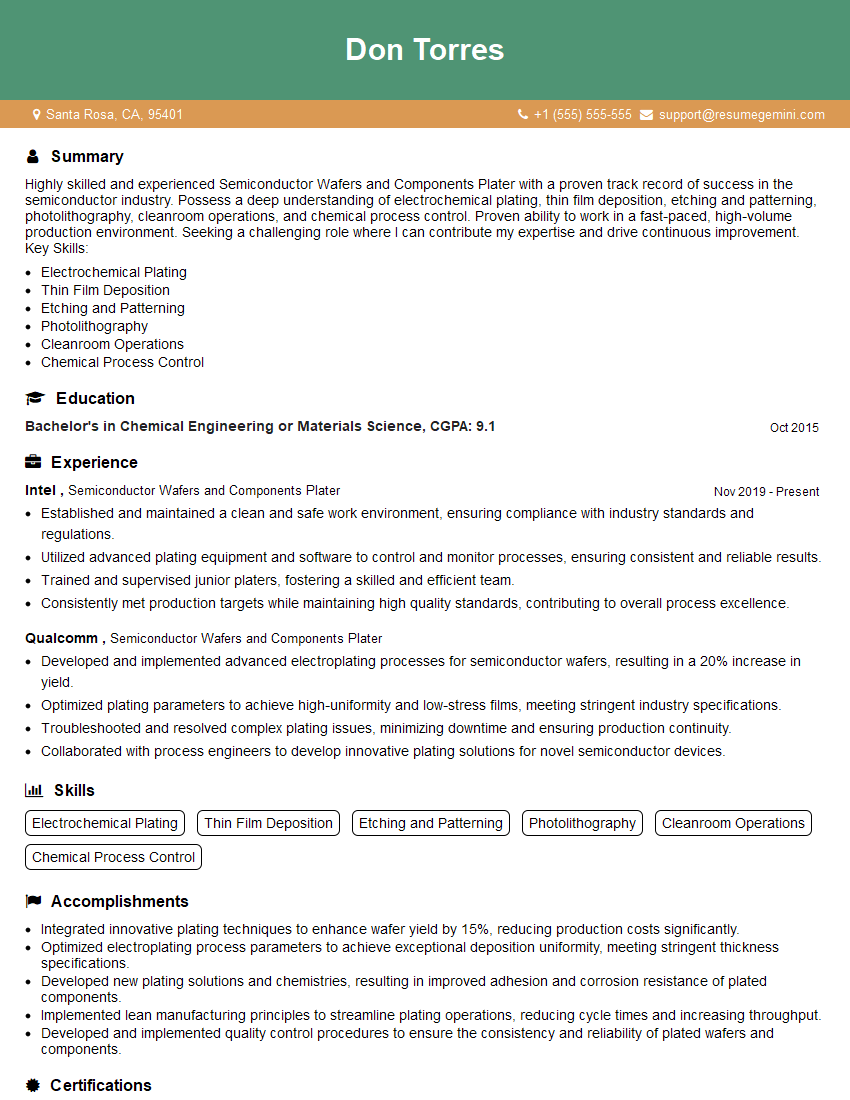

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Wafers and Components Plater

1. What are the different types of plating processes used in the semiconductor industry?

There are various plating processes used in the semiconductor industry, including:

- Electroless plating

- Electroplating

- Immersion plating

- Solder plating

- Gold plating

2. What are the critical parameters to control in electroplating?

Current density

- Affects the thickness, morphology, and quality of the plated film

- High current densities can lead to rough deposits and poor adhesion

- Low current densities can result in slower plating rates and thinner deposits

Bath temperature

- Affects the solubility of metal ions and the rate of deposition

- High temperatures can lead to faster plating rates but also increase the risk of defects

- Low temperatures can result in slower plating rates and more uniform deposits

Solution composition

- Determines the type and properties of the plated film

- Concentration of metal ions, complexing agents, and additives affect the deposition process

- Impurities can lead to defects and poor quality deposits

3. Describe the different techniques used for measuring the thickness of plated films.

Techniques used for measuring the thickness of plated films include:

- X-ray fluorescence (XRF)

- Scanning electron microscopy (SEM)

- Ellipsometry

- Atomic force microscopy (AFM)

- Cross-sectional analysis

4. What are the common defects in plated films and how can they be prevented?

Common defects in plated films include:

- Pin holes: Caused by gas bubbles or impurities in the plating solution

- Nodules: Caused by high current densities or impurities in the plating solution

- Cracks: Caused by stress in the plated film or thermal expansion mismatch

- Poor adhesion: Caused by improper surface preparation or contamination

These defects can be prevented by:

- Properly controlling plating parameters

- Using high-quality plating solutions

- Ensuring proper surface preparation

- Implementing quality control measures

5. What are the safety precautions that need to be taken when working with plating chemicals?

When working with plating chemicals, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, lab coat, and safety glasses

- Handle chemicals in a well-ventilated area

- Avoid contact with skin and eyes

- Dispose of chemicals properly according to local regulations

- Be aware of the potential hazards of each chemical

6. What are the environmental regulations that apply to the plating industry?

The plating industry is subject to various environmental regulations, including:

- Clean Water Act: Regulates the discharge of wastewater from plating operations

- Clean Air Act: Regulates the emission of air pollutants from plating operations

- Resource Conservation and Recovery Act: Regulates the disposal of hazardous waste from plating operations

- Toxic Substances Control Act: Regulates the use and disposal of certain toxic chemicals used in plating

7. What are the latest advancements in plating technology?

Some of the latest advancements in plating technology include:

- Selective plating: Allows for the deposition of metal only in specific areas of a substrate

- Nanoplating: Allows for the deposition of ultra-thin, uniform films with controlled crystal structure

- Pulse plating: Improves the quality and properties of plated films by using a pulsed current

- Advanced materials: Development of new plating materials with improved properties, such as higher corrosion resistance and electrical conductivity

8. What are the challenges facing the plating industry?

The plating industry faces a number of challenges, including:

- Environmental regulations: Increasingly stringent environmental regulations make it more difficult and expensive to dispose of plating waste

- Rising costs: The cost of raw materials and energy has been increasing steadily, which puts pressure on plating companies

- Competition: The plating industry is a global market, and companies face competition from low-cost producers in other countries

- Technological advancements: Rapid advancements in plating technology make it difficult for companies to keep up with the latest developments

9. What are your strengths and weaknesses as a Semiconductor Wafers and Components Plater?

My strengths include:

- Expertise in electroplating and electroless plating techniques

- Strong understanding of plating chemistry and metallurgy

- Experience in optimizing plating processes for various applications

- Excellent troubleshooting skills

- Attention to detail and quality control

My weaknesses include:

- Limited experience with some of the latest plating technologies

- Not yet certified in all areas of plating

10. Why are you interested in working as a Semiconductor Wafers and Components Plater at our company?

I am interested in working as a Semiconductor Wafers and Components Plater at your company because I am passionate about the semiconductor industry and I believe that my skills and experience would be a valuable asset to your team.

I have been working in the plating industry for the past 5 years, and I have experience in a variety of plating techniques, including electroplating, electroless plating, and immersion plating.

I am also familiar with the different types of plating equipment and materials used in the semiconductor industry, and I have a strong understanding of the quality control procedures that are required to ensure that plated products meet the highest standards.

I am confident that I can use my skills and experience to help your company produce high-quality semiconductor wafers and components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Wafers and Components Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Wafers and Components Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Semiconductor Wafers and Components Plater, you will be responsible for the electroplating of semiconductor wafers and components.

1. Electroplating

You will be responsible for:

- Setting up and operating electroplating equipment

- Monitoring the plating process and adjusting parameters as needed

- Ensuring that the plated wafers and components meet specifications

2. Plating Chemistry

You will be responsible for:

- Understanding the chemistry of the plating process

- Maintaining the plating solutions

- Troubleshooting plating problems

3. Substrate Preparation

You will be responsible for:

- Preparing the wafers and components for plating

- Cleaning and etching the wafers and components

- Applying seed layers

4. Quality Control

You will be responsible for:

- Performing quality control tests on the plated wafers and components

- Maintaining records of quality control data

- Investigating and resolving quality control issues

Interview Tips

To ace your semiconductor wafers and components plater interview, you should do the following:

1. Research the company

Learn about the company’s culture, products, and services. This will help you answer questions about why you want to work for the company and how your skills and experience can benefit them.

2. Practice your answers to common interview questions

Prepare for questions about your experience, skills, and qualifications. You should also be able to articulate why you are interested in the position and why you would be a good fit for the company.

3. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. You should also be on time and prepared to answer questions about your qualifications.

4. Be enthusiastic and positive

Show the interviewer that you are excited about the opportunity to work for the company. Be positive and enthusiastic about your skills and experience, and be willing to answer questions about your qualifications.

Next Step:

Now that you’re armed with the knowledge of Semiconductor Wafers and Components Plater interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Semiconductor Wafers and Components Plater positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini